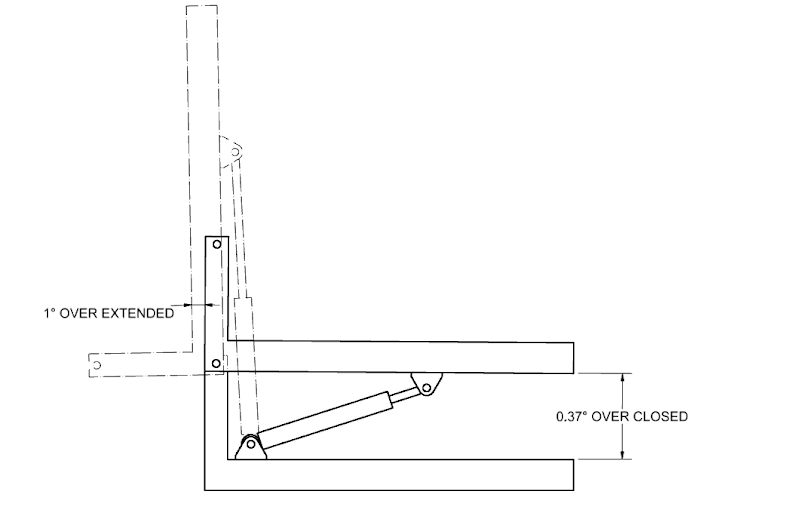

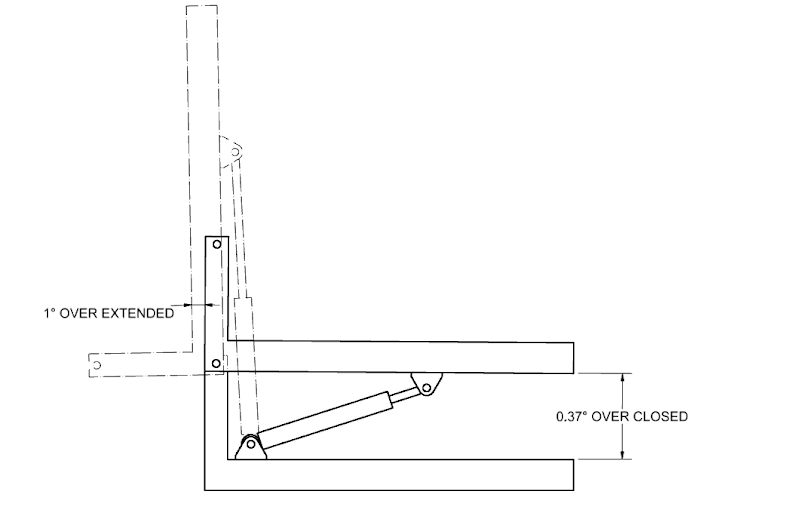

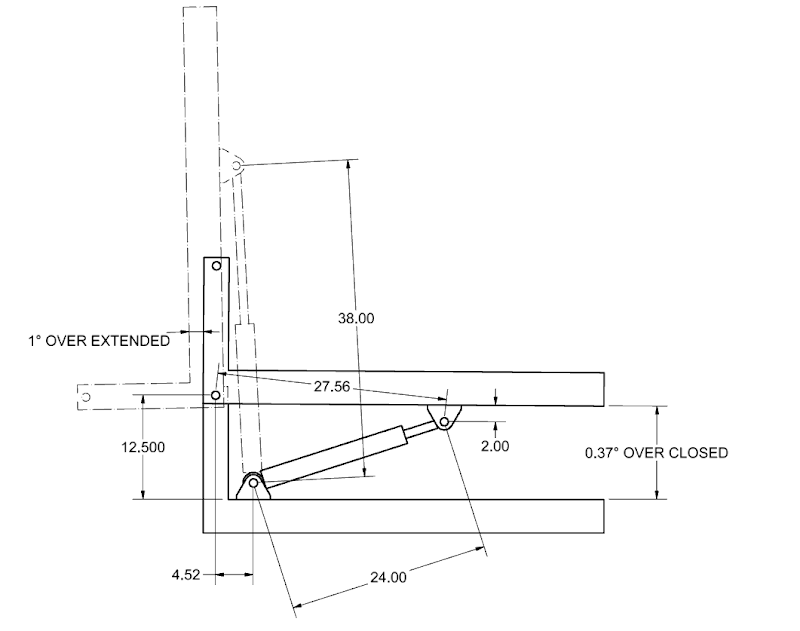

just becase you can figure it out, doesnt mean it doesnt work... the way i had it the rod mount on the beam should be around 10" from beam pivot, and the cylinder base mount would be around 32" laterally from the center line of the beam pivot, that would leave you with about an inch of overstroke and 1/2" of stroke left when in the down position.

its hard to figure out exact measurements because i dont have all of the measurements...

either way will work fine, and a 14 inch stroke cylinder is more than enough for what youre doing. just for comparisons, the log lift on the splitter i built is capable of nearly 180 deg. of movement with just an 18" stroke cylinder, and will lift over 1000 lbs. (only a 2-1/2" cylinder), and the distance between the lift pivot ans the cylinder pivot is less than 8"...