ChoppyChoppy

Tree Freak

Can you make the photos bigger? The ones you have are real small and go blurry when I zoom in.

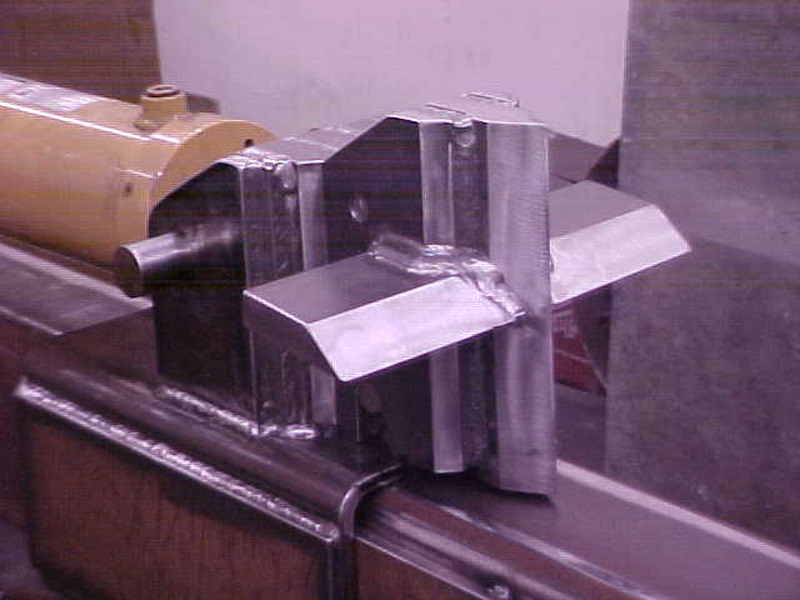

The wings are about a 2/3rds chisel cut. The bottom side has a very slight taper but I can grind them to a straight cut. I tipped the wings forward a bit to help keep it from binding back into the beam but it was a trial thought. I am hoping running the wings higher up in the wedge will help push the wood out easier without binding but I may be way off.Is your 4 way wings double beveled? If so, you are going to have have pieces get wedged between the wing and the bottom plate or your slide plate.

Also, use soft bolts. If you put in hardened bolts, if something isn't right, you want those bolts to break, so you don't twist the beam and bend that.

I'm not sure how, when I click on the pics it brings them up full screen and clear. If I click the thumbnails they are small and blurry.Can you make the photos bigger? The ones you have are real small and go blurry when I zoom in.

Ya it loaded, he looks sound as a poundThis one load for you? It big enough to see for me.View attachment 539211

I'm ordering the steel for the bottom plate today. Would you suggest adding 2 2x2 bars the full length of the bottom or 1x3 bars the full length? The 1x3 is how I see it done on big residential splitters for saleIf you were having issues splitting ash I would suggest there is a problem with your current setup. May be a worn out pump, cylinder blow by or your wedge is too aggressive. Do you have access to a pressure gauge or is there one on there? Most splitters have no issue with elm as it is just stringy and makes it hard for manual wedging or doing it by hand. I'm running a 5 inch and it can split most everything you throw at it. With a 7, even at a lower idle, you are going to have to be careful. Totally agree with muddstopper, your base plate is going to bend quickly.

I have a wedge on the ram but mine is horizontal only. I never liked vertical and get around that with a lift boom for the big stuff. I made a quick release system for my wedges that requires no tool and is just a single pin and drop pin to hold it.

Lower pin is fixed and drops over. Rock back and slide pin in and a chopped bolt is dropped in from the top to lock in place.

Make sure if you make a 4 way to not have the contact surface all at once on the cross. Let the upright start to split then the secondary horizontal. have it lift up as shown above to avoid pinching. Honestly, with what you have now I wouldn't recommend doing it as it'll just bend your base faster. I was going to do a 6 inch on mine and I have the strength there to handle it. I decided not to as the speed was more important than the 2 times in 1000 I might need a 6 inch bore and I'm running a 28 gpm pump. I know you have the 7" allready but I don't think you'll be happy in the long run. Once again, if you do decide to move forward with it, be careful. A 7 inch can pop those bolts and they will fly like missiles. I split for a while with a guy how had a 8" cylinder with 12, 5/8" grade 8 bolts on his slide. He ended up putting a guard over the bolts after he got hit with one. He ran that thing off an excavator.

1 x 3 with the 1" thickness welded to the bottom. You have a lot of tons going there force wise. Even with that I would take it easy as I'm pretty sure you are going to see some beam flex as well.I'm ordering the steel for the bottom plate today. Would you suggest adding 2 2x2 bars the full length of the bottom or 1x3 bars the full length? The 1x3 is how I see it done on big residential splitters for sale

1 x 3 with the 1" thickness welded to the bottom. You have a lot of tons going there force wise. Even with that I would take it easy as I'm pretty sure you are going to see some beam flex as well.

What part of the wedge?How many passes (weld) did you make on your wedge?

Any way to gusset or box in the end of the beam so you don't tear that plate off?

It should be rather solid. I appreciate your response. I also am curious, most the replies I've received have all stated that I will have gobs of tonnage pushing on the base plate which is obvious with a 7 inch ram but that being said. I've compared the way I'm building this and the overall size of everything I'm using from the beam, slide, to the top and bottom plates and nothing sold here locally from the 27 ton to the 37 ton splitters even compare. I know I've rented 37 ton splitters and they have split everything I've put in front of them and cut through what wouldn't split. Am I thinking correctly that if the 37 will push through everything then this splitter though has the capability of producing 59 tons, more than likely will never operate at near thathe tonnage because the wood will split long before building that tonage?I was looking at the base plate and where the wedge where welded together. Pictures never do justice but sounds like you have everything tied together pretty well.

Are those a pair of White's Hiding in the corner?This one load for you? It big enough to see for me.View attachment 539211

Haha let's just keep it to engine blocks and not my leg. Definitely want to be safe with, even if I drop it down to 4o tons it won't hurt my feelings as long as it splits and the pump will be sipping Mai Tais running at 2000 PSIFrom what everyone says the cheaply made ones aren't true of there advertised tonnage. My preference is speed, fast cycle time and enough power to run a 6 way wedge. You'll have enough power to crush engine blocks and anything else you decide to destroy.