You know what your doing , everything I see is right .If you were having issues splitting ash I would suggest there is a problem with your current setup. May be a worn out pump, cylinder blow by or your wedge is too aggressive. Do you have access to a pressure gauge or is there one on there? Most splitters have no issue with elm as it is just stringy and makes it hard for manual wedging or doing it by hand. I'm running a 5 inch and it can split most everything you throw at it. With a 7, even at a lower idle, you are going to have to be careful. Totally agree with muddstopper, your base plate is going to bend quickly.

I have a wedge on the ram but mine is horizontal only. I never liked vertical and get around that with a lift boom for the big stuff. I made a quick release system for my wedges that requires no tool and is just a single pin and drop pin to hold it.

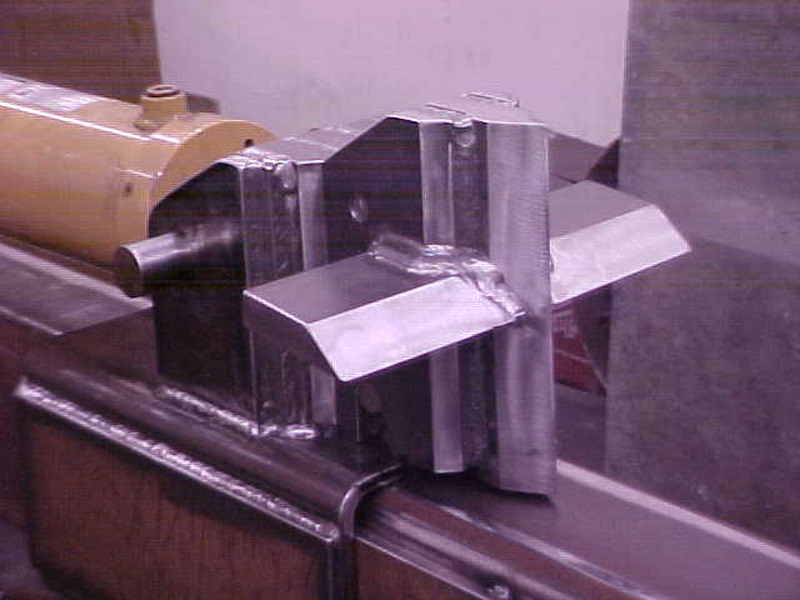

Lower pin is fixed and drops over. Rock back and slide pin in and a chopped bolt is dropped in from the top to lock in place.

Make sure if you make a 4 way to not have the contact surface all at once on the cross. Let the upright start to split then the secondary horizontal. have it lift up as shown above to avoid pinching. Honestly, with what you have now I wouldn't recommend doing it as it'll just bend your base faster. I was going to do a 6 inch on mine and I have the strength there to handle it. I decided not to as the speed was more important than the 2 times in 1000 I might need a 6 inch bore and I'm running a 28 gpm pump. I know you have the 7" allready but I don't think you'll be happy in the long run. Once again, if you do decide to move forward with it, be careful. A 7 inch can pop those bolts and they will fly like missiles. I split for a while with a guy how had a 8" cylinder with 12, 5/8" grade 8 bolts on his slide. He ended up putting a guard over the bolts after he got hit with one. He ran that thing off an excavator.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New splitter build

- Thread starter Charlie Pendleton

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I ran a 4 inch cylinder for years , get the wedge right . Your going to break more than wood . The local welding shop would no longer weld my wedge back on ,I had the money an paid .Not going to throw them under the bus ,they do good work . The back an forth action cause mental fugitive . What I seen your going to break more than wood .

Just a few observations looking at the pics and and some of the replies. The base of the wedge isnt going to have the same stress levels as a wedge on beam design simply because the wedge is being pushed by the cyl. If the wedge had been welded to the beam, I would be very suspect of breaking that wedge off. Base is pretty tall and welded flush to the end of the hbeam. The gusset from beam to base might keep it from ripping off, but the potential is still there that it might start to rip away from the beam. The height will surely allow the base to bend, even with the sqbar welded to the bottom. The 4way wedge I aint really sure how well it will function. The side wings are pretty short and positioned pretty far back from the leading edge. My thoughts are that instead of making a clean 4way split, the short wings will just force the first split wider apart and possibly just get stuck in the second split and not split those pieces cleanly. Looking at the pic's on the first page, it looks as if the cyl is just mounted to a piece of plate that is flush welded to the end of the beam, if this is the case, that will probably be the first area of failure and breakage. The cyl base will have just as much pressure applied to it as the base welded to the opposite end. If the cyl base hasnt been boxed by now, it needs to be before using the splitter. Actual tonnage, based on a 7in cyl with the suggested pressure setting of 2000psi, will make a true 33.5tons of force. More than enough power to split pretty much anything thrown at it, also enough power to find all the weak spots in the build design.

Charlie Pendleton

ArboristSite Operative

I'm listening and changing things quite often. Thanks for you suggestions. The bottom plate extends 9 1/2 inches above the beam. Is that to tall? The pictures make it look much taler than it is. The beam is 12 inches. I'll add some plate to box the rear beam.Just a few observations looking at the pics and and some of the replies. The base of the wedge isnt going to have the same stress levels as a wedge on beam design simply because the wedge is being pushed by the cyl. If the wedge had been welded to the beam, I would be very suspect of breaking that wedge off. Base is pretty tall and welded flush to the end of the hbeam. The gusset from beam to base might keep it from ripping off, but the potential is still there that it might start to rip away from the beam. The height will surely allow the base to bend, even with the sqbar welded to the bottom. The 4way wedge I aint really sure how well it will function. The side wings are pretty short and positioned pretty far back from the leading edge. My thoughts are that instead of making a clean 4way split, the short wings will just force the first split wider apart and possibly just get stuck in the second split and not split those pieces cleanly. Looking at the pic's on the first page, it looks as if the cyl is just mounted to a piece of plate that is flush welded to the end of the beam, if this is the case, that will probably be the first area of failure and breakage. The cyl base will have just as much pressure applied to it as the base welded to the opposite end. If the cyl base hasnt been boxed by now, it needs to be before using the splitter. Actual tonnage, based on a 7in cyl with the suggested pressure setting of 2000psi, will make a true 33.5tons of force. More than enough power to split pretty much anything thrown at it, also enough power to find all the weak spots in the build design.

Charlie Pendleton

ArboristSite Operative

I'm listening and changing things quite often. Thanks for you suggestions. The bottom plate extends 9 1/2 inches above the beam. Is that to tall? The pictures make it look much taler than it is. The beam is 12 inches. I'll add some plate to box the rear beam.

Attachments

Charlie Pendleton

ArboristSite Operative

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

second pics do give a better view. Base plate for cyl mount looks plenty beefy. The bottom plate isnt as long as it looks in previous pics. certainly not as tall as the pusher plate on my 6way splitter, but not as beefy as mine either. The pusher on my processor is 27x27 inches.

Charlie Pendleton

ArboristSite Operative

That's a big pusher. I imagine it splits some woodsecond pics do give a better view. Base plate for cyl mount looks plenty beefy. The bottom plate isnt as long as it looks in previous pics. certainly not as tall as the pusher plate on my 6way splitter, but not as beefy as mine either. The pusher on my processor is 27x27 inches.

still in the assembly mode, but hope to do 12 splits at a time.

Charlie Pendleton

ArboristSite Operative

ChoppyChoppy

Tree Freak

second pics do give a better view. Base plate for cyl mount looks plenty beefy. The bottom plate isnt as long as it looks in previous pics. certainly not as tall as the pusher plate on my 6way splitter, but not as beefy as mine either. The pusher on my processor is 27x27 inches.

Got dang. The pusher on my processor is maybe 8x10"

Can't wait for the report! Oh and video of course.

Yea, but you only split pecker poles. I plan on up to 30in dia rounds.Got dang. The pusher on my processor is maybe 8x10"

ChoppyChoppy

Tree Freak

Yea, but you only split pecker poles. I plan on up to 30in dia rounds.

We do 30" rounds on the 18-20 it. 22-24" will fit through the saw, but it will split bigger. My 15-20 can fit 18".

- Joined

- Jan 14, 2002

- Messages

- 4,800

- Reaction score

- 12,596

- Location

- North of Goderich, Ontario, Canada

My pusher on my 36" stroke splitter is 12x12. I'm going to weld another 4" on the top because I stack 12" rounds and split 2 at a time sometimes. I also don't have any weld beads on the pusher face. I've decided that I want the round to move instead of testing my welds or the bolts holder the pusher on. I cut my rounds pretty straight so no worries of sliding much anyway.

Paint, I never paint. Paint means it's done, I'm never done, I'm always improving things. At least that's what I keep telling my wife.

Paint, I never paint. Paint means it's done, I'm never done, I'm always improving things. At least that's what I keep telling my wife.

Just picking at you a little. I believe your processor just has the straight knife wedges with wings, so pushing with a short pusher plate will push the round all the way thru the wedge. With a box wedge, if your not pushing the entire round, it can split and not push the top of the round thru the wedge.We do 30" rounds on the 18-20 it. 22-24" will fit through the saw, but it will split bigger. My 15-20 can fit 18".

ChoppyChoppy

Tree Freak

Yeah 6 way, they make an 8 way as well.

Have watched a box wedge on a Cord King, can't say I'd choose that type, makes alot more junk.

Have watched a box wedge on a Cord King, can't say I'd choose that type, makes alot more junk.

Charlie Pendleton

ArboristSite Operative

Haha, found a nice big leak after 2nd split. To the hydraulic shop I go dee doh dee doh dee doh

93green12v

ArboristSite Operative

Best way to find them. I had my supply line fitting that was loose but wasn't spraying just a slow leak once everything was warm.

Charlie Pendleton

ArboristSite Operative

Ya so mine sprayed a gallon right at my kids bikes and yard toys, buying degreaser as well what a mess . Bottom cylinder o-ring blew out. Should have been replaced I guess, lolBest way to find them. I had my supply line fitting that was loose but wasn't spraying just a slow leak once everything was warm.

Similar threads

- Replies

- 8

- Views

- 567

- Replies

- 42

- Views

- 2K

- Replies

- 9

- Views

- 398

- Replies

- 2

- Views

- 232

- Replies

- 6

- Views

- 965