blk05crew

I like 'em green

well, mine at least starts and runs, at 180 psi it must be worth twice that....not to mention the chain brake...

Yeah that one on Ebay wasn't even a runner!

well, mine at least starts and runs, at 180 psi it must be worth twice that....not to mention the chain brake...

Yes, I remember that now. How is the shoulder now? I don't remember what the problem was with Brad's saw...I do recall running up to the shop and finding a small piece of fuel line that he wanted for something on it. Still don't sound bad in this video.

Gregg,

Duh....Mark was the one with the bad shoulder...just clicked in my not so sharp mind.

Gregg,

Rebuilt carb and fooling with Lo needle it either runs or dies. Have it set about 1 1/4 open if I recall. This is on my PP 475 which is a Jonsered 2077 clone. Maybe I'll fool with it again today.Did you rebuild the carb?

Gary had a 655 and a P65 at the Poulan 2013 GTG and I wish I could have tried them but was concerned about doing too much with my healing Achilles tendon.

BL Snelling had a nice 655 there as well but couldn't get it running right.

well, mine at least starts and runs, at 180 psi it must be worth twice that....not to mention the chain brake...

Gary, I would like yo see pics of that saw if you could arrange it.

The only part issue with that saw is the starter pulley. If it did go and you can't find one you could easily buy a clapped out 3400 and swap the flywheels out and use a 3400 pulley which are easy to find. The air filters are scarce but if you take care of the one you have it won't be an issue.

It does have a muffler mod. Just the removal of the very restrictive spark screen, and drilled the center baffle holes some. It already has a side outlet, just like the 4000 does.

Gregg,

Figure I may as well do the muffler mod while I'm cleaning the saw up. I took off the spark screen already. What size did you drill the center baffle holes?

I just drill them out and leave enough meat between the holes when done.I clean up the holes and surfaces with files after I drill them. Just to remove burrs metal bits and stuff. Just so they don't find their way inside the engine.

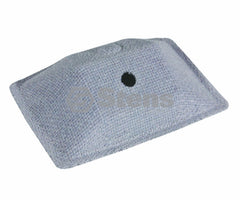

I assume you have this filter, you should on the 375. They are the same as a 4000. They are nylon and can be washed easy enough. I don't replace them until they get a hole, torn or something. There was a seller on Ebay that use to stock these. Just have to do a little searching.

Gregg,

What's the purpose for the baffle anyway? Seems like an unnecessary part.

Edit: Never mind, sounds like it serves as a spacer to prevent over tightening and possibly provides back pressure. Good search feature on this site.

Good, no holes or tears on my filter so I guess all it needs is a good cleaning. There's some fine wood particles stuck on it and possibly some oil.

Just use the dish soap like you said and some warm tap water and let it soak for a while and then rinse it out and let it dry.

I have also washed these two styles of Poulan filters and kept as long as the the mesh is completely covered with cloth. These are just internet images...What's the purpose for the baffle anyway? Seems like an unnecessary part.

Edit: Never mind, sounds like it serves as a spacer to prevent over tightening and possibly provides back pressure. Good search feature on this site.

Good, no holes or tears on my filter so I guess all it needs is a good cleaning. There's some fine wood particles stuck on it and possibly some oil.

There's no other function of the foam other than keeping dirt out from behind the oil pump cover. If you are at least flush with the opening you're OK.I have to send/post a pic of my oiler foam plug thingy. Man I just totally screwed the name up lol. I was able to use the foam pipe insulation but I don't think it sticks out of the opening far enough. Looking at a pic of yours, it seems I pushed my plug in too far.