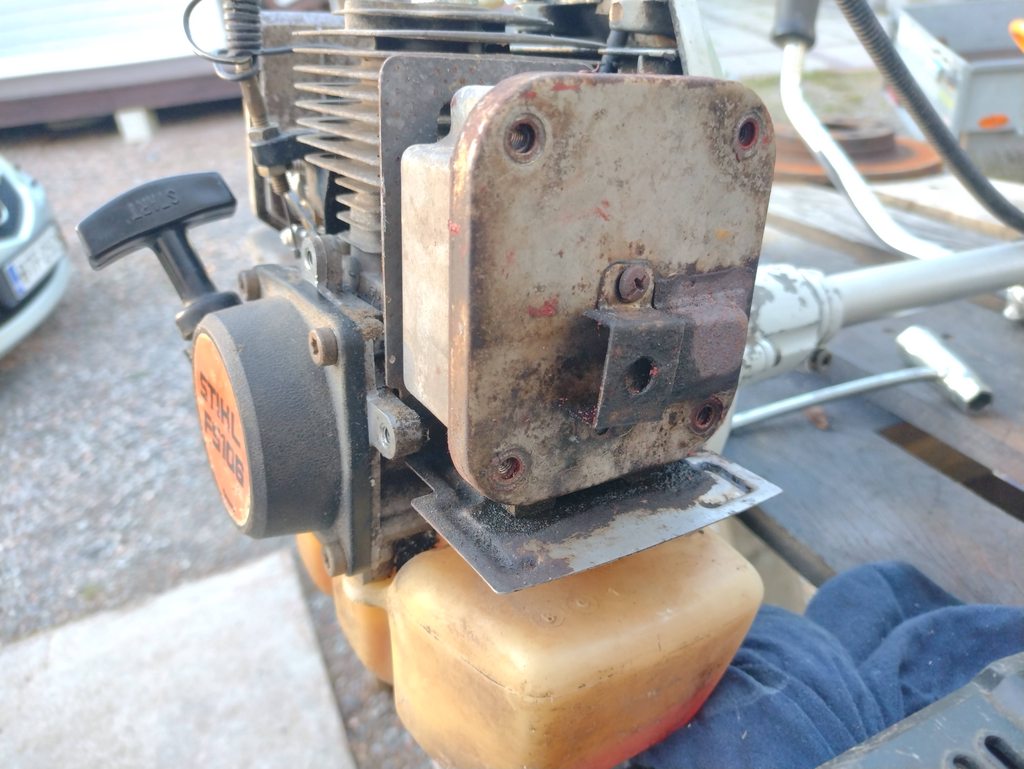

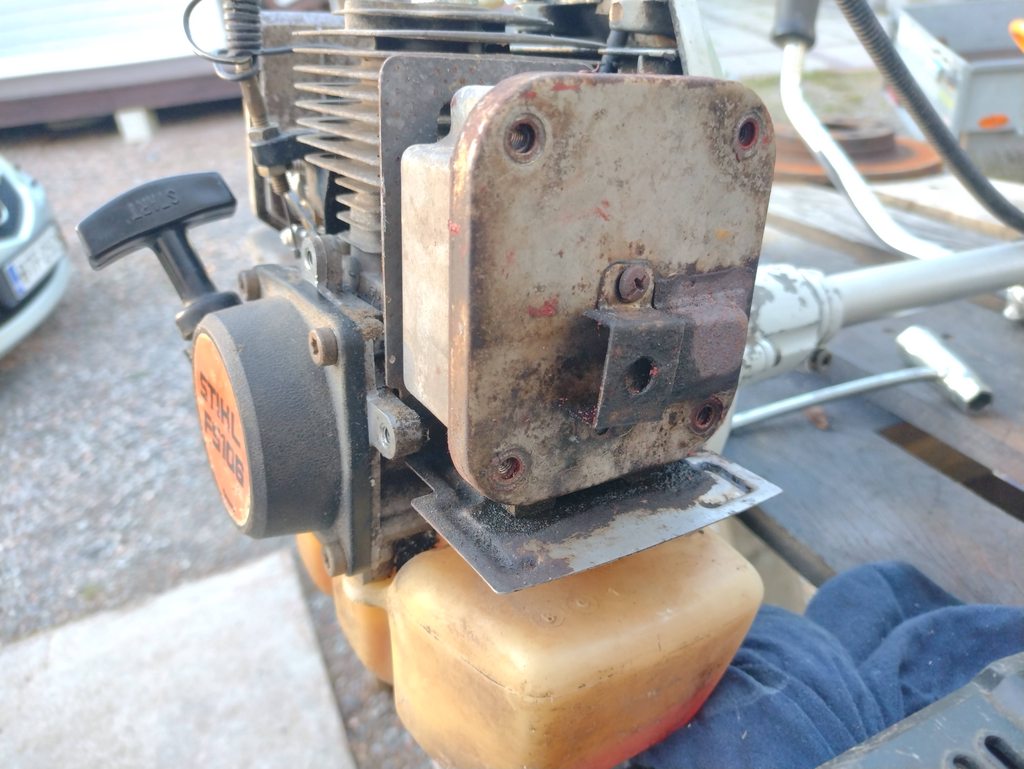

I've been thinking about opening up this muffler on my brush cutter to get a little more oomph. But not sure how to go about it. This one has a long pipe inside the main opening and then the exhaust does a 90 degree bend again before leaving. So I guess I could remove the last forced bend and it'd flow a bit more freely, or I could remove the tube inside. Both maybe?

I'm not even sure it's a good idea. I do like this thing, it has a decent amount of power for it's small size, it's old too, maybe late 80s early 90s. If it could have a little more grunt I'd like that.

I'm not sure how opening up the muffler would change the characteristics of the machine, does it give more power across the whole register, does it make it weaker at lower rpms and stronger at higher rpms, or does it just allow it to rev faster? I'm just not sure it's a good idea or not.

I'm not even sure it's a good idea. I do like this thing, it has a decent amount of power for it's small size, it's old too, maybe late 80s early 90s. If it could have a little more grunt I'd like that.

I'm not sure how opening up the muffler would change the characteristics of the machine, does it give more power across the whole register, does it make it weaker at lower rpms and stronger at higher rpms, or does it just allow it to rev faster? I'm just not sure it's a good idea or not.