Trigger-Time

Addicted to ArboristSite

Do you put slack in the chain, when your done cutting for the day?

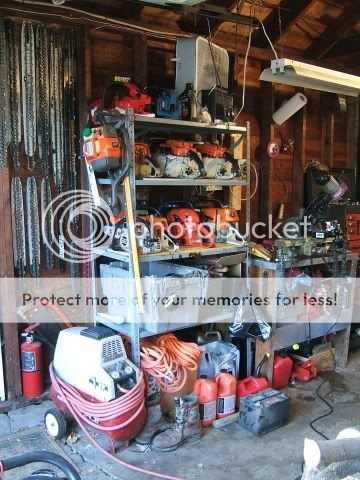

computeruser said:Nope. I take it off the saw and put it on the to-be-sharpened hook next to the grinder. Then I clean the saw, set the powerhead on the shelf, and hang the bar in its spot on the wall-o-bars-and-chains.

computeruser said:Nope. I take it off the saw and put it on the to-be-sharpened hook next to the grinder. Then I clean the saw, set the powerhead on the shelf, and hang the bar in its spot on the wall-o-bars-and-chains.

Nope, because I'm just gonna be cutting again the next day.Trigger-Time said:Do you put slack in the chain, when your done cutting for the day?

Mike Maas said:Why would one put slack in the chain?

computeruser said:Nope. I take it off the saw and put it on the to-be-sharpened hook next to the grinder. Then I clean the saw, set the powerhead on the shelf, and hang the bar in its spot on the wall-o-bars-and-chains.

Mike Maas said:You'd have to adjust the chain pretty tight while it's hot, to have it shrink and damage the bearings. But I'm sure it's been done, or they wouldn't have he warning.

Just about the time they make something idiot proof, they make a bigger idiot.

treeclimber jul said:I just set the chain when cold and when I am done the chain is a little loose on the bar so no need to loosen.

Paul B said:Steel expands .000006 inchs per degree F per inch of length. So lets assume you are using a 24 inch bar. So the chain length is about 60 inches. Lets say its 30 degerees outside and the chain temp rises to 90 while in use. Thats 60 inches * a 60 degree change in temp * .000006 inches = 21/1000 expansion. I don't think I will adjust to compensate for this.