Blue42

ArboristSite Operative

I've been pulling 300 lb slabs up a steep hill with block and tackle. It's a killer on about a 35 degree incline. (Yea. 35. I measured it.) After taking an hour per slab yesterday and about 20 times up and down the hill pulling, adjusting, de-snagging ropes, etc., I'm done. Thinking about an ATV winch. It will not be on a vehicle. I'll bolt it to some 2x4s.

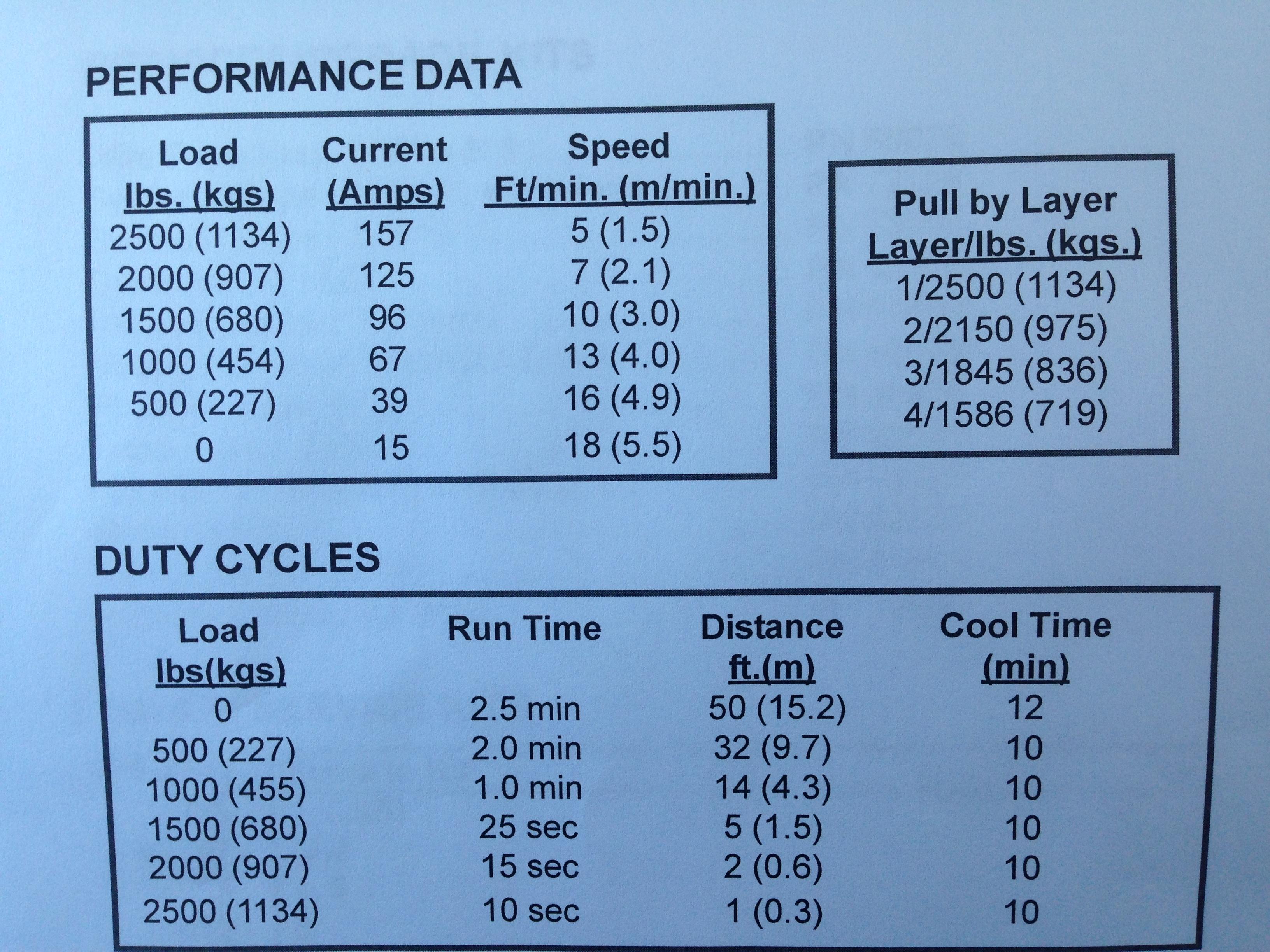

Anyone done this before or have any advice? I think it should be fine, but I also think the motor might not like it, since its normal use is pulling one thing 10-20 ft, one time. Not 6 things 100 ft, one after the other.

Anyone done this before or have any advice? I think it should be fine, but I also think the motor might not like it, since its normal use is pulling one thing 10-20 ft, one time. Not 6 things 100 ft, one after the other.