benp

Addicted to ArboristSite

Dang!!! Nice!!

Someone's gonna be happy!!!!

Someone's gonna be happy!!!!

the 660 has a 2mm longer stroke if you stroked a 385(54mm bore) crank 2mm and you would have a 91.6cc saw which is the exact same cc's of a 660. I would really like to see that build I bet I know what saw would win . I will give you a hint it starts with an H for HAHAHA huskys are always faster. LOL

Looks REAL strong there Stumpy! What RPMs do you have her tuned to? What's the compression?

That thing must pull like a freight train now.

Nice work as always!

I'd like to see how she does in bigger wood.

I hear thats were they really shine.

Thanks Brad, it's tuned to 13,300 & pullin around 10,200 in the wood. Comp is @210 @ shouldn't get much higher since I didn't have to replace the rings.

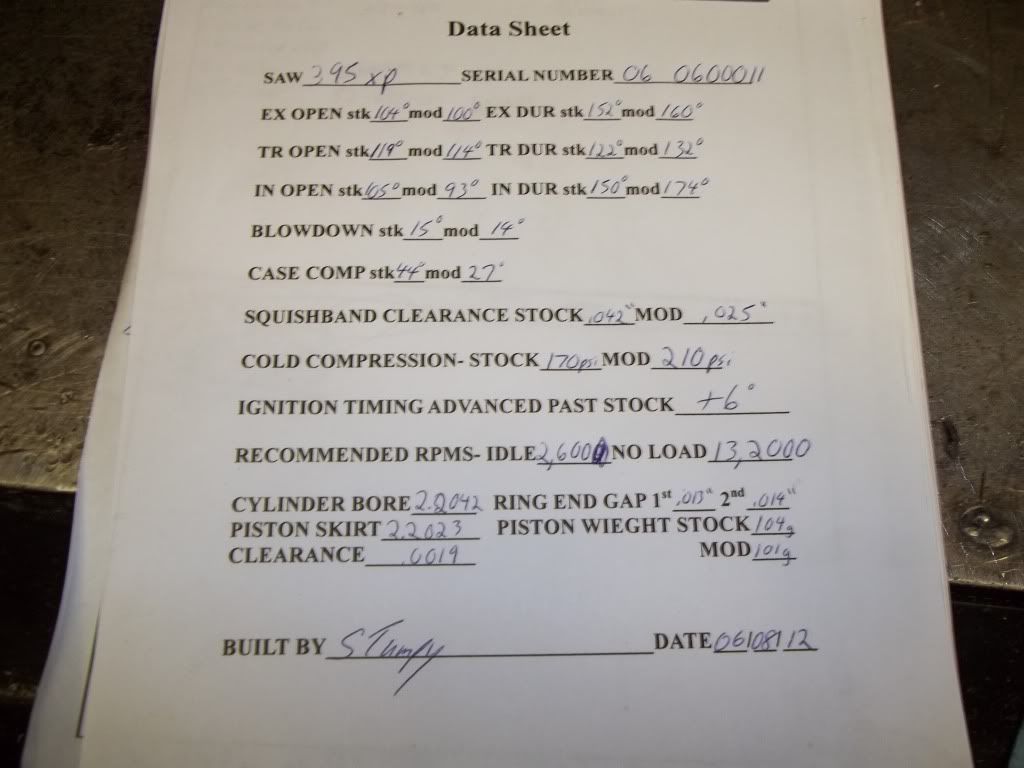

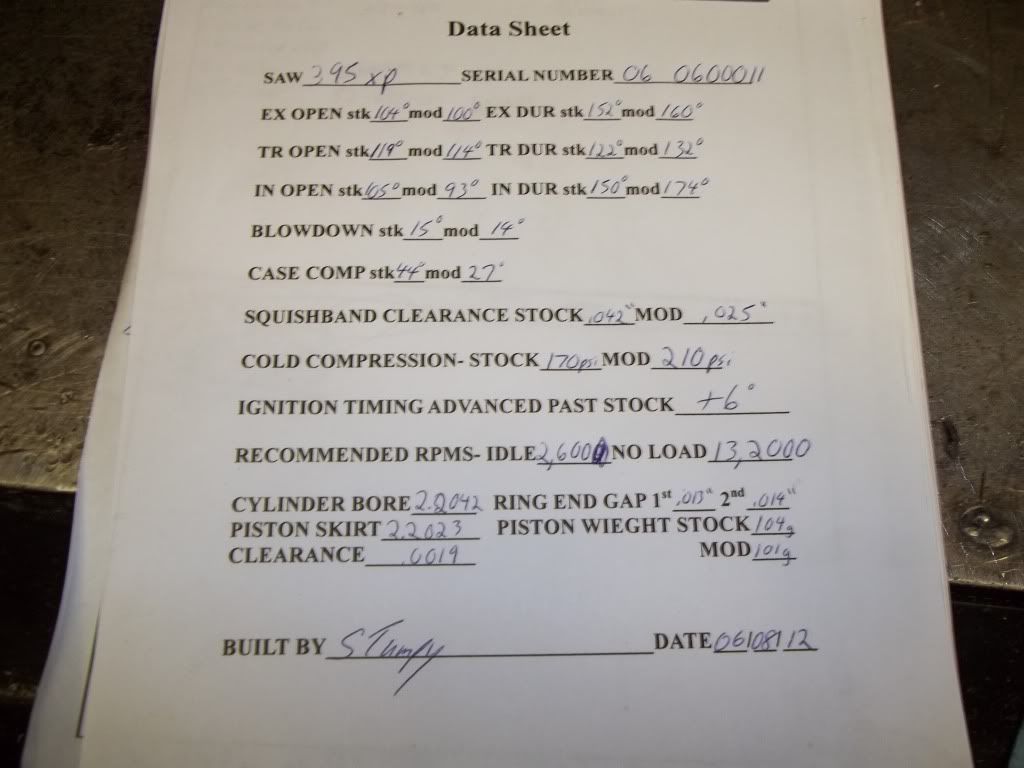

Here's the Data sheet with all the info on it.

Nice work! But I have a couple of questions. First how much was removed from the squish band ? Second why so little blow down? I thought that this saw would gain from more blow down and less case volume. I have ran alot of 395xp's over the years but never a ported one I would like to port one I have even though about stroking the crank to 40mm and useing my NOS 2100 thin ring piston to make a quad transfer port 398xp or a 3100xp but I know whatever you want to call it it would scream. I have heard of guys stuffing the cases on these saws and also have full circle cranks made for them to reduce case volume. So why go so big with the lower transfers? I am not criticizing I just am trying to learn what I can before I try one. I was also wondering if the lower transfers on a 066 can be opened up like that or not I am trying to get a 064 BB saw running the way I would like it to and I think that I just don't have enough case volume any thoughts or suggestions would be greatly appreciated. I thought if I could open up the lowers like you have on this 395 that it might give me a what I need the only other thing I was thinking of doing was going to a 395 piston using just the top ring and a spacer plate in between the case and cylinder.

Hey Stumpy,

That data sheet is a nice touch. Do you include a copy of it for the customer or is it just for your personal reference?

My 394 is set at 13,3 - 13,2 also and barks along quite happily there.uttahere2:

Again, great work Stumpy!! :msp_thumbup:

.png) . What's the case comp degrees? Intake closed till bottom dead center?

. What's the case comp degrees? Intake closed till bottom dead center?I like the data sheet stump. What's the case comp degrees? Intake closed till bottom dead center?

intake closed till the upper transfers open. During that time the crank case is being pressurized.

, i gotch ya!

, i gotch ya!Enter your email address to join: