Dear Lee,

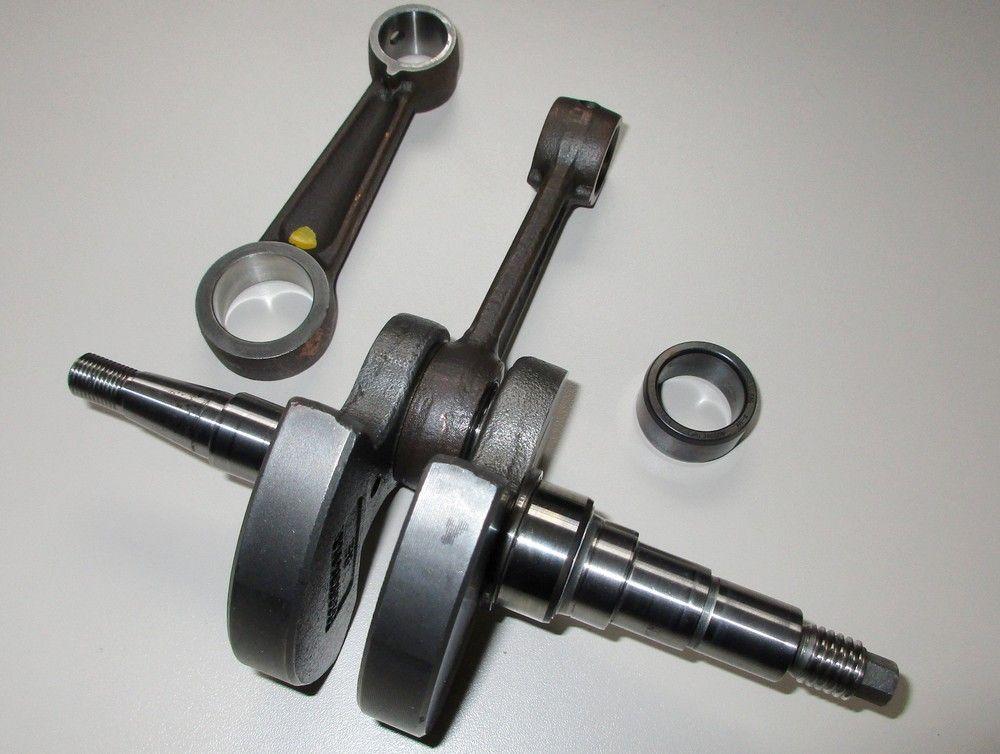

had to dig out your thread, because I had to pull apart my 2nd Dolmar 166.

Different from the description (while buying more than 7 year ago) it needs major revision.

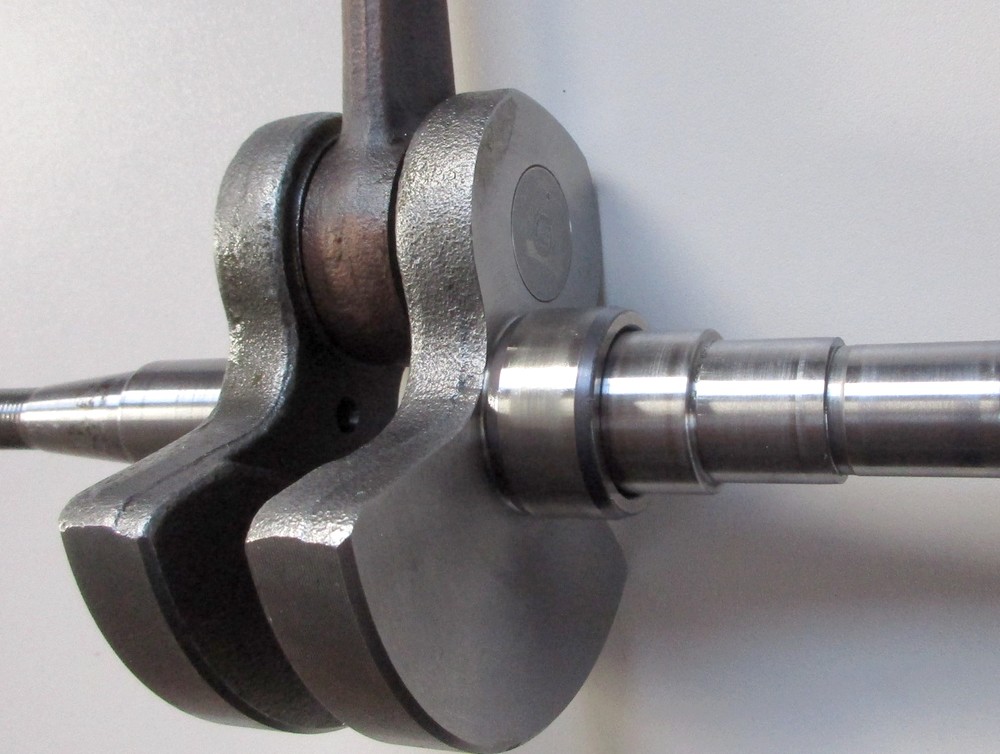

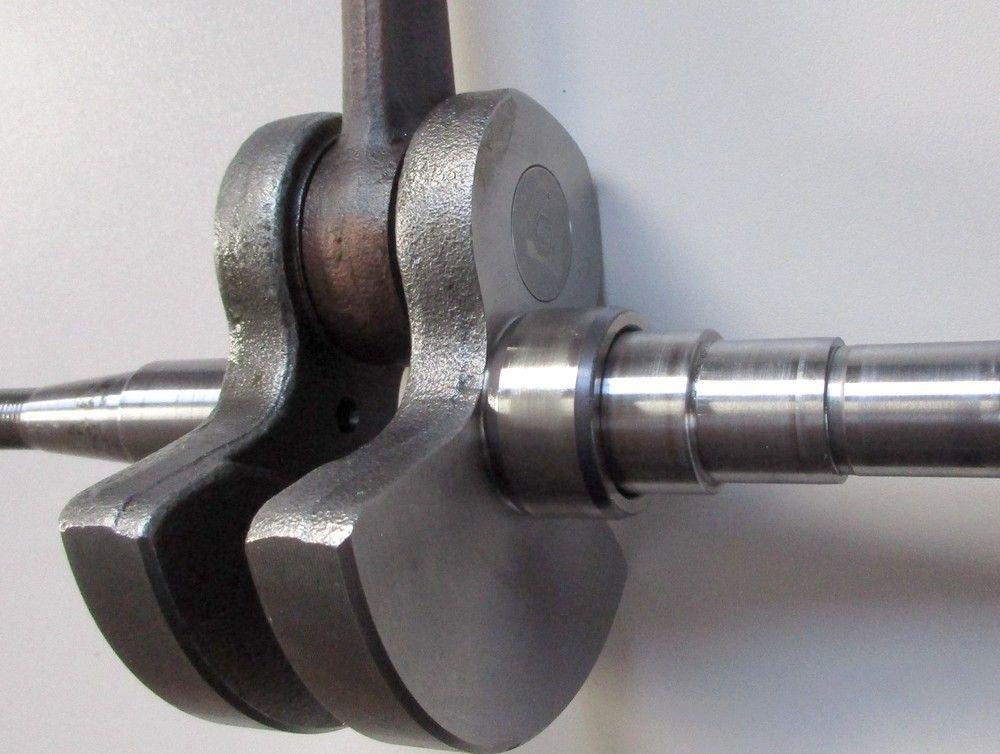

Today I removed the crank. The inner bushing of the roller bearing makes me nerveous, it is just a plain cylinder

which might come with the bearing of type NU2041E.

That means not "step" at the inner end, to prevent the crank from getting pushed to the bearing.

Seems that the one who assembled that particular saw made a major mistake ?

(glad that I finally pulled it apart completely)

At your picture, however, the inner ring is different:

Where do I get such a ring from ? Bearing Type "NJ" comes with such a ring, however, I have seen the type "NU" in various crank cases of 166.

Was it part of the original Dolmar bearing ?

I cannot find it on the IPL, it is not drawn separately.

Did they combine 2 bearings, inner ring from NJ and outer ring and rolls from type NU ?

Or is it just an NJ204E, and the outer ring of those bearings is also labelled "NU" as they might be the same ?

https://www.ekugellager.de/nj204-ec...SA&utm_term=kugellager&utm_content=Kugellager

would be glad if someone could give some information

best Chris