That long line your using for a suction hose is going to cause you problems with the way it mounted. You have it looped up and over the splitter, higher than the top of the tank,and down to the pump. What this line is going to do is drain back to tank everytime the machine is cut off and make the pump work to create suction when you first start it up, Fix is easy, just loop the hose around behind the machine and then to the pump. Just keep the loop lower than the hyd fluid level.

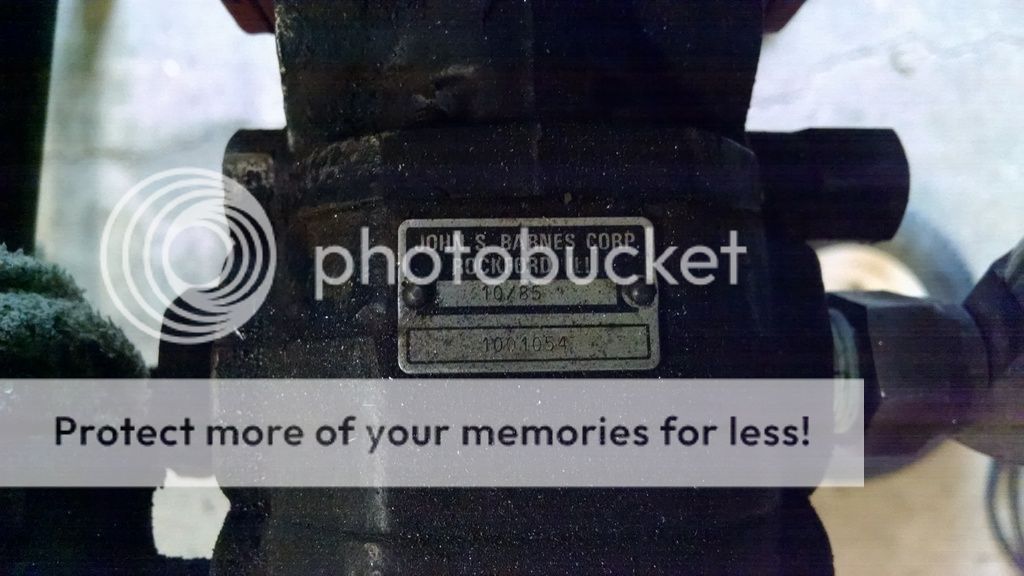

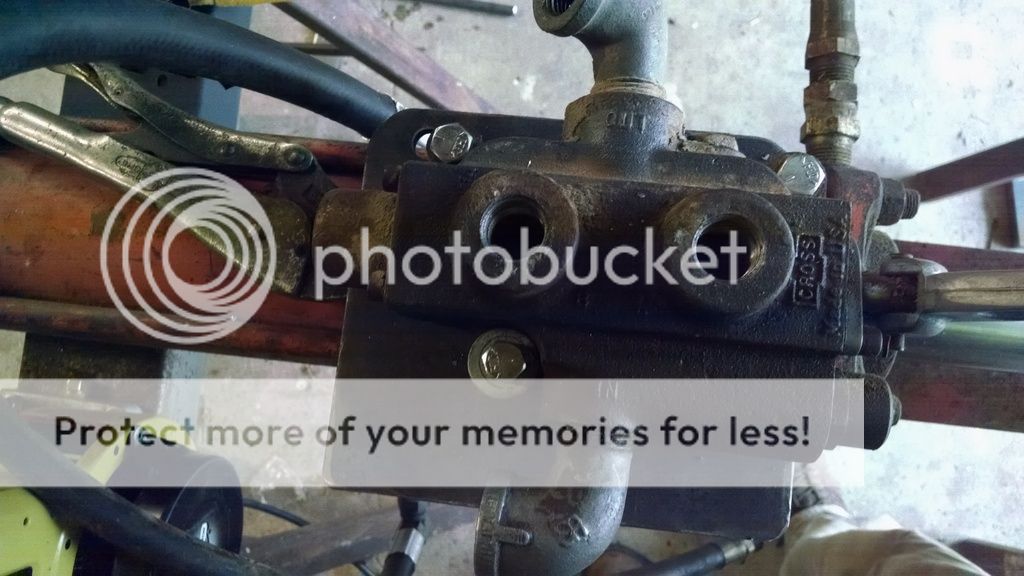

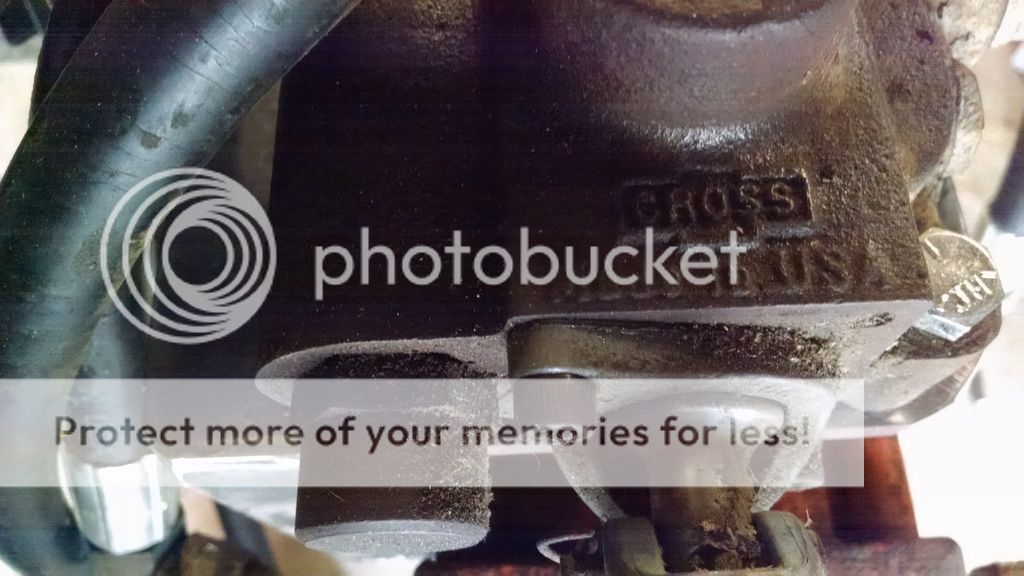

I cant help you on size of the pump, but the Barnes is a good quality pump, if the engine will pull it, it should work fine. Your valve looks like it came off some other piece of equipment. Nothing wrong with it if it works for you, just have a question. Is the lever spring centered, meaning when you let off the lever, does it return to center on its own, or do you have to manually shift it from work to center? You might want to think about changing out those galvanized plumbing fitting also. They are not designed to work in a high pressure hydraulic system, I think the high pressure rating on one of those fittings is something like 650psi, your machine could see pressure spikes in excess of 5 times that amount. Not changing them out could result in a heavy oil bath, and loss of hydraulic oil at the least, and possible personal harm. That looks like a galvanized fitting on your pressure line (IN) to valve, I would at least change it for a high pressure fitting. The (OUT), return line should ever see high pressure so you can leave it in if you want to. I cant tell what kind of fitting are on the cylinder, but if they are galvanized, or water pipe, they should be changed out as well.