Stihlofadeal64

Addicted to ArboristSite

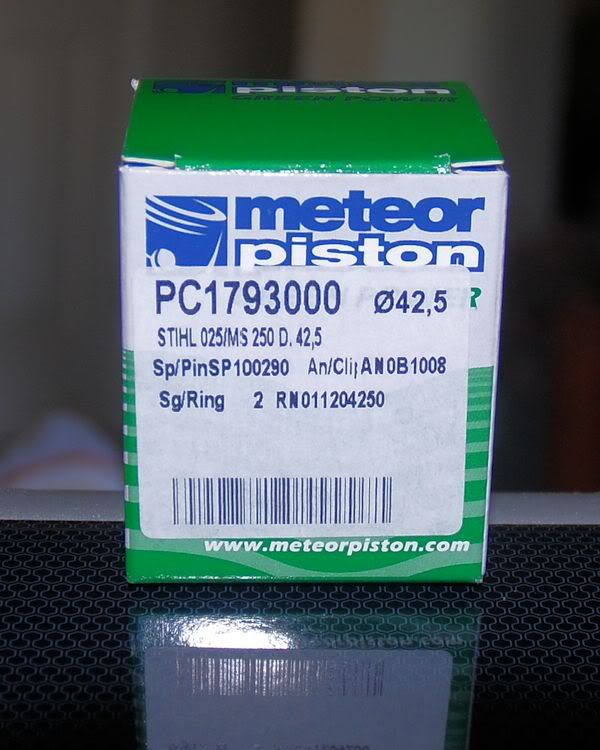

Hey guys, thought I'd throw this question out. I have a box full of parts I've had for ages of Stihl 025/MS250 stuff. I understand there are a few differences in the saws. I've probably built (in days past 25 or 30 already but its been a while.) I picked up a parts saw this weekend from a guy and have some leftover stuff to pull the saw together. Here's my dilemma. One of the differences between the MS250 and the 025 is .5mm. I don't have a dial bore gauge so I can't measure inside.

Since the cylinder is slightly tapered it's hard to tell whether it is a MS250 or an 025.

I have both pistons (42 and 42.5mm). They both fit in the cylinder, one very snugg, and the other with some clearance (without the rings they both dropped clean).

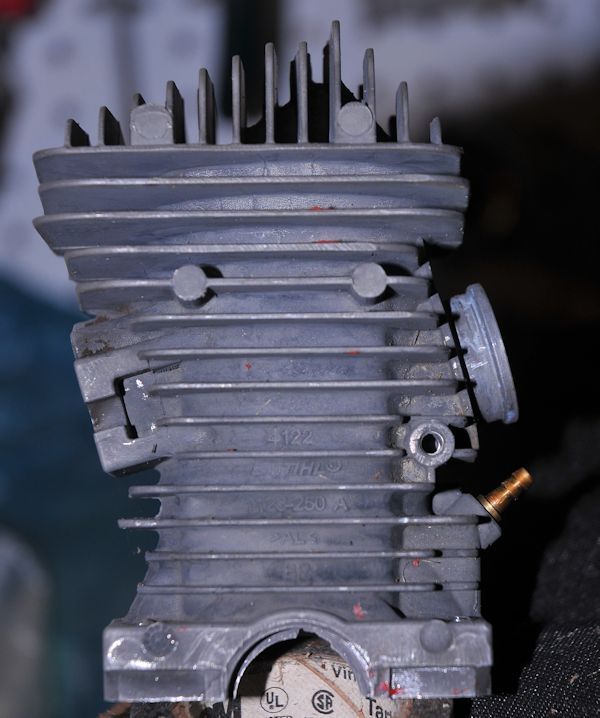

The markings on my cylinder read as follows:

1123-025

>AL<

BR

(not sure if Stihl indicated in some code which one this is or not, maybe someone can chime in. I know on the 029's and the 029supers and the MS290's they have specified 45 and 46mm).

Is there a way I can check the cylinder to see what it is by the markings, or another way I can measure to identify without a dial bore gauge? I am not sure how much clearance should be between the piston and the wall without the rings, or can I check/measure or identify it some other way. It's late and all this may be fuzzy, but I'm just trying to verify. Thanks in advance for your replies. Tommy

Since the cylinder is slightly tapered it's hard to tell whether it is a MS250 or an 025.

I have both pistons (42 and 42.5mm). They both fit in the cylinder, one very snugg, and the other with some clearance (without the rings they both dropped clean).

The markings on my cylinder read as follows:

1123-025

>AL<

BR

(not sure if Stihl indicated in some code which one this is or not, maybe someone can chime in. I know on the 029's and the 029supers and the MS290's they have specified 45 and 46mm).

Is there a way I can check the cylinder to see what it is by the markings, or another way I can measure to identify without a dial bore gauge? I am not sure how much clearance should be between the piston and the wall without the rings, or can I check/measure or identify it some other way. It's late and all this may be fuzzy, but I'm just trying to verify. Thanks in advance for your replies. Tommy