You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 07/07S prototype

- Thread starter Steffen

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Steffen

Collect old Stihls. Contra, 07, 08...

SawTroll

Information Collector

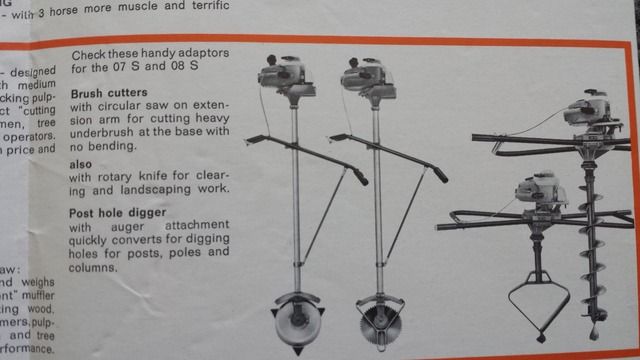

I guess I am going to have to take a picture for sure now!!Heres a reference to the 07s being used for a brushcutter/post hole digger attachment, but only shows the 08s as the powerhead?

Thanks for that picture.

BBB

Steffen

Collect old Stihls. Contra, 07, 08...

Im starting to clean up the prototype to put it on display.

I thought the cylinder was the same as on the production 07, but compared it to my early 07 and there were som difference on the top of the cylinder, the top rip and the casting ports.

I also found out that the muffler is sandcast as the rest of the saw. It has rough surface and is also a bit diffent that the production muffler and bigger.

I might have showed it before, but the oilpump is diffent. it dont has the adjusting of oilflow.

When i took the muffler of the saw a crank stop bolt showed up, like on the Contra. The production 07 dont has that either.

The carburator looks like an Tillotson, but dont have the name anywere. Not the HL code either. It has the codes on the pictures, dos anyone knows this carburator??

.

I thought the cylinder was the same as on the production 07, but compared it to my early 07 and there were som difference on the top of the cylinder, the top rip and the casting ports.

I also found out that the muffler is sandcast as the rest of the saw. It has rough surface and is also a bit diffent that the production muffler and bigger.

I might have showed it before, but the oilpump is diffent. it dont has the adjusting of oilflow.

When i took the muffler of the saw a crank stop bolt showed up, like on the Contra. The production 07 dont has that either.

The carburator looks like an Tillotson, but dont have the name anywere. Not the HL code either. It has the codes on the pictures, dos anyone knows this carburator??

.

Steffen

Collect old Stihls. Contra, 07, 08...

I have found one of the early 07 from the start of the productionline. This has a special cylinder design that looks alot like the one on my prototype. This design was only used in a short period of time in the start of the production of the 07. Im happy to join this saw in my collection.

You can see the differens to the normal 07/07S cylinder.

.

You can see the differens to the normal 07/07S cylinder.

.

Steffen

Collect old Stihls. Contra, 07, 08...

I got some very sad news from Stihl today.

I have mailed them about my prototype and showed pictures and videos of the saw. But they dont belive that this saw is made by Stihl.

They told me it was a copy of there product and they had no call of a prototype or testsaw of the model 07.

Im not the person that gives up, and i still belive this is a prototype of the Stihl 07. The saw is sandcastet and most of the saws parts have the part nr. in the casting with the nr. 1107 in front.

The guy i have been talking to will now go back to the experts he had showed my saw to and hear them what parts they would like to se the part nr. on to belive this is a saw made by Stihl.

Now i just need some more patience ;-)

This saw look like tis made in the samw way as the early Contras from 1959 and has the serial nr. stamped on an id plate from the Contra.

Lets see what the future brings.

If someone knows anything, or know were there is others of these prototype/testsaws.... Please contact me!

Thanks.

I have mailed them about my prototype and showed pictures and videos of the saw. But they dont belive that this saw is made by Stihl.

They told me it was a copy of there product and they had no call of a prototype or testsaw of the model 07.

Im not the person that gives up, and i still belive this is a prototype of the Stihl 07. The saw is sandcastet and most of the saws parts have the part nr. in the casting with the nr. 1107 in front.

The guy i have been talking to will now go back to the experts he had showed my saw to and hear them what parts they would like to se the part nr. on to belive this is a saw made by Stihl.

Now i just need some more patience ;-)

This saw look like tis made in the samw way as the early Contras from 1959 and has the serial nr. stamped on an id plate from the Contra.

Lets see what the future brings.

If someone knows anything, or know were there is others of these prototype/testsaws.... Please contact me!

Thanks.

SawTroll

Information Collector

Good luck with your search for information!

The statement about no prototype or test saw(s) is indeed an odd one. Of course there were, regardless if they can dig up documents that confirm it or not.

The statement about no prototype or test saw(s) is indeed an odd one. Of course there were, regardless if they can dig up documents that confirm it or not.

I wonder who would have copied the 07...

Steffen

Collect old Stihls. Contra, 07, 08...

I got a pile of parts today, and something caught my eye.

The cylinder on the left is missing the round ports that is used to port the cylinders transfer ports after casting. Its after sealed of with a plug. I have never seen this cylinder design before! They are both with the early type sparplughole.

It is a Mahle cylinder and the bore is the same as all other 07 cylinders.

This is very interesting. Has any of you seen this design before?

The cylinder on the left is missing the round ports that is used to port the cylinders transfer ports after casting. Its after sealed of with a plug. I have never seen this cylinder design before! They are both with the early type sparplughole.

It is a Mahle cylinder and the bore is the same as all other 07 cylinders.

This is very interesting. Has any of you seen this design before?

SawTroll

Information Collector

I don't think there are many that has seen any of this before - you are much closer to the source of those saws than most members here, so your chance of finding the really early versions likely is much higher.

SawTroll

Information Collector

I wonder who would have copied the 07...

East Germans, or other Eastern block nations maybe - but most likely no-one.

Steffen

Collect old Stihls. Contra, 07, 08...

At the moment im working on an early 07 with serial 164xxx. I have replaced the bearings and noticed that the old bearings was a brand that i have not seen before.

SRO Switzerland, i then google the name and it turend out the brand was bought by Renault in 1946 and the name was changed to SNR "Société Nouvelle de Roulements" (the "new bearing company"). All other 07 i have worked on had FAG/INA bearings.

I bit fun to find bearings that is that old in a saw from 1961, might just clean and keep these old bearings.

After i fittet the bearings and was putting the crankcase back together, i noticed that the crankcase was different as well... The wall between the oil and fuel tank is a single wall and the fueltank is smaller than other 07...

I went and look in my documents about the 07 and found two pictures to show you what im tanking about.

It turns out the crankcase was changed at some point in the start of the productionline to make a dobble wall and a smaller oiltank.

The oiler is also a more simple design at the start of the production, i have added a picture of that as well.

i hope you enjoy it

.

SRO Switzerland, i then google the name and it turend out the brand was bought by Renault in 1946 and the name was changed to SNR "Société Nouvelle de Roulements" (the "new bearing company"). All other 07 i have worked on had FAG/INA bearings.

I bit fun to find bearings that is that old in a saw from 1961, might just clean and keep these old bearings.

After i fittet the bearings and was putting the crankcase back together, i noticed that the crankcase was different as well... The wall between the oil and fuel tank is a single wall and the fueltank is smaller than other 07...

I went and look in my documents about the 07 and found two pictures to show you what im tanking about.

It turns out the crankcase was changed at some point in the start of the productionline to make a dobble wall and a smaller oiltank.

The oiler is also a more simple design at the start of the production, i have added a picture of that as well.

i hope you enjoy it

.

Steffen

Collect old Stihls. Contra, 07, 08...

Now a little bit about the oilpump.

Its a mecanic pump that is driven by a rod pushed up and down by a spring and a cam on the crankshaft.

The design on the pump was changed very early in production and after that kept the design for the rest of the production of the 07 and 07S.

On my prototype, there is no adjustment of the oilflow. That came on the production model from the start of the production. To adjust the flow you loosen the bolt on the outside of the pumphousing and turn the adjusterarm.

Back to the design change that came very early in the production, probely within the first year of production. I found out why they changed the design after i rebuild the last partsaw i had. Its an early 07 and has the early type oilpump. I have rebuild the saw and it runs great, but then stopped pumping oil for the chain.

I had cleaned all the pipes and the pickup hose. It must be in the pump were the fault was. I took the pump out and found out that the rod from the crankshaft and the oilpump was not connected anymore.

With a little cleance in the housing were the rod goes up to the crankshaft, it can make the little tap on the wheel on the oilpump to pup out of the two rings on the rod when the rod is pushed up and down.

That is what happed here, and i think that happend to many 07 in the start of the production.

Stihl fixed this by mounting the rod on the oilpump by a brace and now the cleance in the hole up to the crankshaft cant make the rod vibrate and the tap on oilpump to come out of contact with the rod. They also fit an oilring in the crankcase to make better sealing to the crankcase. This oilring can be seen on top of the brace on the rod. This oilring is not in the early design.

Its a mecanic pump that is driven by a rod pushed up and down by a spring and a cam on the crankshaft.

The design on the pump was changed very early in production and after that kept the design for the rest of the production of the 07 and 07S.

On my prototype, there is no adjustment of the oilflow. That came on the production model from the start of the production. To adjust the flow you loosen the bolt on the outside of the pumphousing and turn the adjusterarm.

Back to the design change that came very early in the production, probely within the first year of production. I found out why they changed the design after i rebuild the last partsaw i had. Its an early 07 and has the early type oilpump. I have rebuild the saw and it runs great, but then stopped pumping oil for the chain.

I had cleaned all the pipes and the pickup hose. It must be in the pump were the fault was. I took the pump out and found out that the rod from the crankshaft and the oilpump was not connected anymore.

With a little cleance in the housing were the rod goes up to the crankshaft, it can make the little tap on the wheel on the oilpump to pup out of the two rings on the rod when the rod is pushed up and down.

That is what happed here, and i think that happend to many 07 in the start of the production.

Stihl fixed this by mounting the rod on the oilpump by a brace and now the cleance in the hole up to the crankshaft cant make the rod vibrate and the tap on oilpump to come out of contact with the rod. They also fit an oilring in the crankcase to make better sealing to the crankcase. This oilring can be seen on top of the brace on the rod. This oilring is not in the early design.

Similar threads

- Replies

- 15

- Views

- 43K

- Replies

- 106

- Views

- 6K