Show pics of the side of the sprocket drum where the chain brake band rubs and the chain brake band. A monster saw like the 291 will easily pull through a baby spruce with the chain brake engaged, even faster if it has the FARM BOSS sticker!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl MS 291 burnt out after 1 hr

- Thread starter west041

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

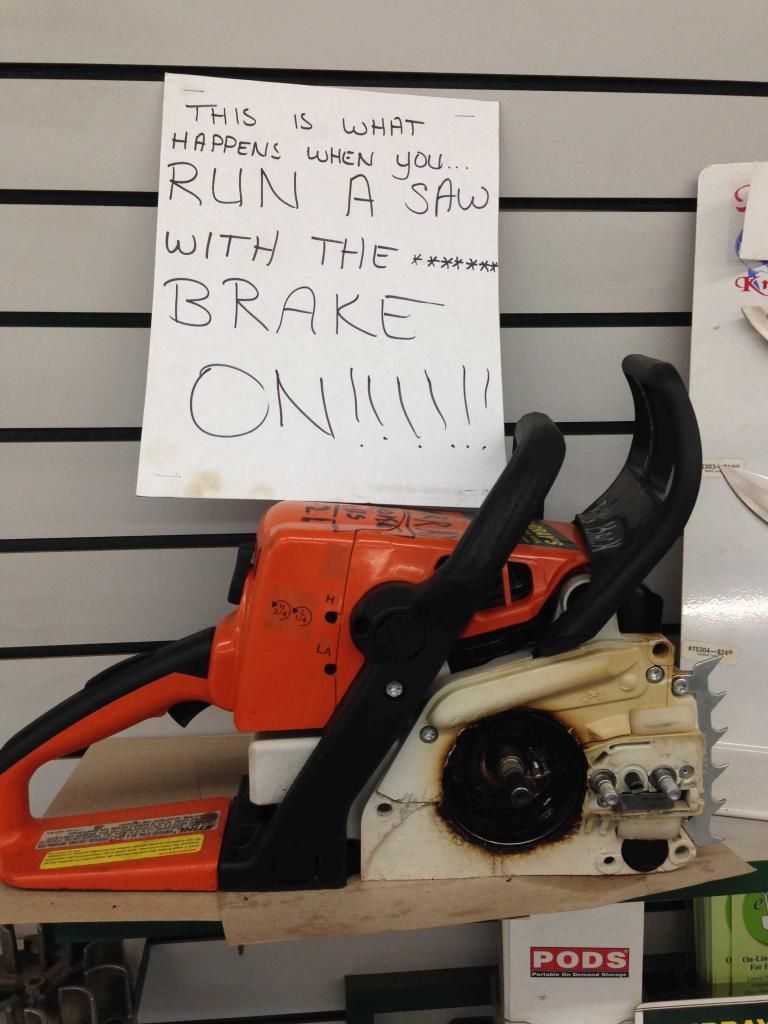

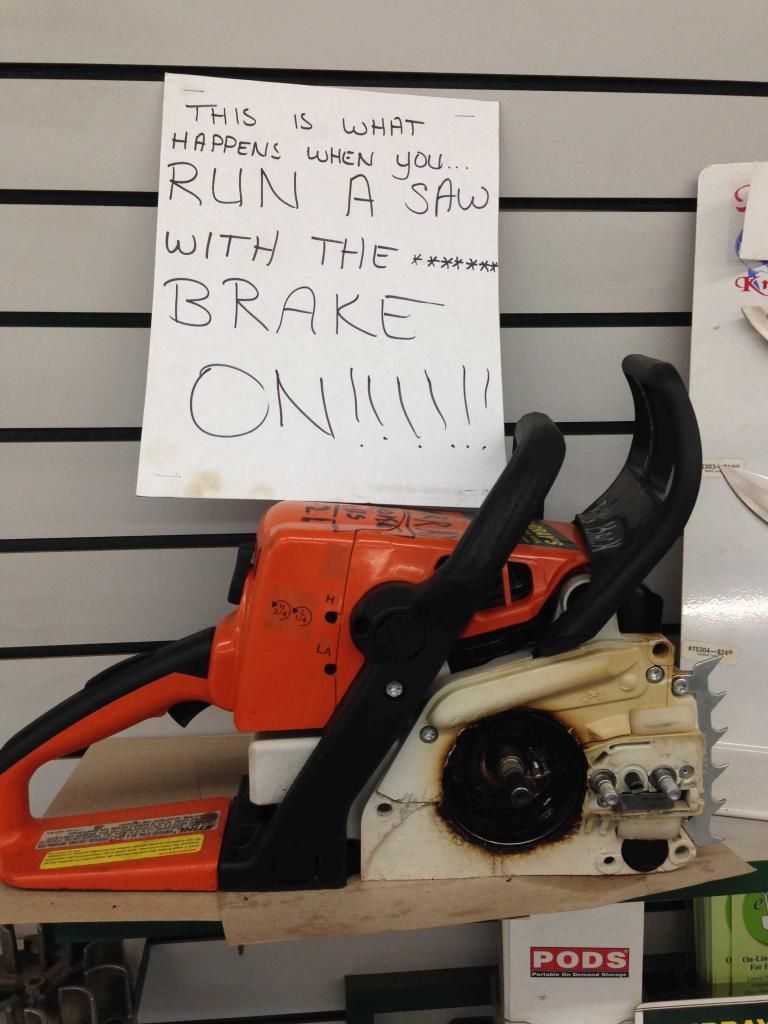

The sap heats up and the water is " boiled " away and it just become harder, coats the brake band and slowly builds up. gets hotter and then begins to bind things up. a good cleaning, perhaps place the power head in a plastic bag and then place it into the fridge get the nice and cold the sap will break off easier. then make a list of the parts you need. I do not blame Stihl as much as I would blame the dealer. If you identify the problem correctly then you can easily get the issue solved. The dealer is asked what they think happened to the unit, Stihl can only base if the saw is worth repairing from what they said. A good cleaning will show you pretty quickly if it is indeed melted or just coated in sap. From the photos I can see you need a new oiler gear, dunno if the brake band is toast, clutch may need a good tear down and cleaning. If you are very lucky all that would be needed are a few parts and a good cleaning.

That is exactly what I was thinking, Stihl or any OEM for that fact relies on info sent to them through their authorized dealers, reps, and repair centers, so the big question is what did your dealer tell Stihl their diagnosis was?

If I was you I would demand to see the dealer's diagnostic report they sent to Stihl.

Burning saw from an unkown reason, the heavyweight 90% fall to the customer . now you see diagnostic reportThat is exactly what I was thinking, Stihl or any OEM for that fact relies on info sent to them through their authorized dealers, reps, and repair centers, so the big question is what did your dealer tell Stihl their diagnosis was?

If I was you I would demand to see the dealer's diagnostic report they sent to Stihl.

I should just stay out of this, but none of the scenarios listed in this thread are Stihl's fault. They cannot control how clean a customer keeps a saw or if it's filled up with junk. From the picture evidence that I can see, it needs a new bearing, brake band, worm gear and probably and oil pump. 15 minutes of work and $60 worth of parts. This is a good case of why it's a good idea to inspect and clean saws when they are being done being used, particularly with sappy softwood.

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,088

Hmmmmm....

brand new saw out on it's first rental from a local company, he cut the tree down with the brake on

just sayin

Dave

brand new saw out on it's first rental from a local company, he cut the tree down with the brake on

just sayin

Dave

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

Okay, that prolly won't buff out...

Is it possible the brake hit while you were running it and you didnt catch it?

Is it possible the brake hit while you were running it and you didnt catch it?

That's why I want to see the side of drum and the brake band....it will be clear if it was left on and the heat from the brake plus the sap could easily damage the plastic as in the picture. I have abused the **** out of a MS290 and it keeps coming back for more. I have a 291 in the garage and it is built similarly to the MS290 (drive line anyway, engine is completely different). I'm usually anti-corporation in these scenarios, but I can't imagine another scenario that could result in the damage...

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,088

the modern saws have a lot less travel in the brake handle so they trip quick enough for the regulations

Dave

Dave

beermeatguns

ArboristSite Member

- Joined

- Apr 9, 2014

- Messages

- 57

- Reaction score

- 81

Yikes. My first post on this thread, I was dubious that could happen, in that the saw would still turn the chain over. I was wrong. My 394 and 3120 won't move the chain at all when the brake is on.

RandyMac

Stiff Member

typical inboard clutch design flaw

SteveSS

Addicted to ArboristSite

Hard to tell from the pics if it's accumulated tree sap that boiled and burned, or if it's blistered plastic from running with the brake on. If I were a claims adjuster at Stihl Corporate, I'd need more definitive proof. Like, toss it in an ultrasonic cleaner and show me before and after pics to prove the tree sap theory. Without real proof like that, I'd be in the "ran it with brake on"camp. Not saying that the OP is a doofus though, because like someone else said......winter time, gloves, loss of sense of feel, etc. It happens. I'd be more inclined to fix it myself than pay labor fees though.

banana boat

ArboristSite Operative

My ms460 will not move the chain if the brake is on even if the saw is at full throttle, how could you cut with the brake on? Actually now that I think of it the manual says to test the brake ingage the brake while the saw is at full throttle and it should stop the chain immediately, never tired seems like it would be a lot of stress on parts.

That explains wYikes. My first post on this thread, I was dubious that could happen, in that the saw would still turn the chain over. I was wrong. My 394 and 3120 won't move the chain at all when the brake is on.

Then that puts Stihl in a bad position now dont it! It aint supposed to do it but they say he did it.My ms460 will not move the chain if the brake is on even if the saw is at full throttle, how could you cut with the brake on? Actually now that I think of it the manual says to test the brake ingage the brake while the saw is at full throttle and it should stop the chain immediately, never tired seems like it would be a lot of stress on parts.

ckelp

just being myself

my aunt let a "friend" barrow her 391. her friend let the day labor run it, he ran it with the chain brake on for two cuts and did identical damage.

id take pics of the saw but i'm watching the kid and i'm lazy

id take pics of the saw but i'm watching the kid and i'm lazy

juttree

ArboristSite Guru

Dull chain+sap+no bar oil= melted plastics. POS saw not worth the plastic it was molded in.

jughead500

Sasquatch

Ooooooo the New Stihl's. Don't ask me about the low hour 311 i bout a while back with non existant Main Bearing cages and 4 BB's bouncing around between the bottom and top end.

Don't ask me about the low hour 311 i bout a while back with non existant Main Bearing cages and 4 BB's bouncing around between the bottom and top end.