Lakeside53

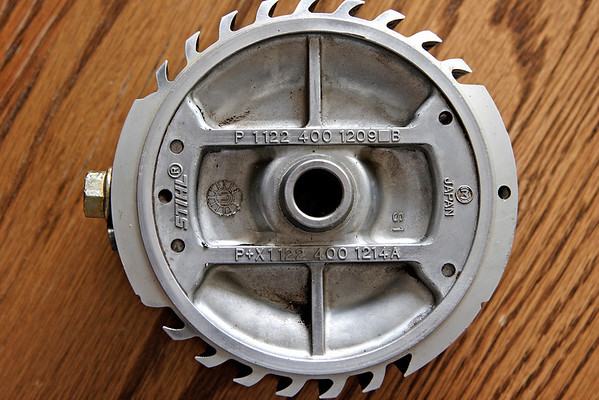

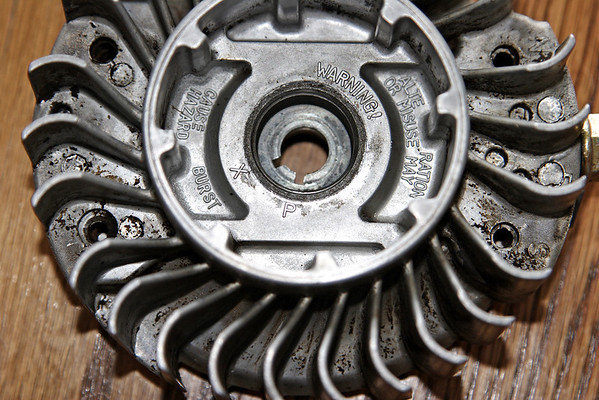

Stihl Wrenching

It is supposed to be unlimited and "smart", but it's not all that common and was discontinued by Stihl. Not sure why... maybe because the saw has to be pulled over at least 900rpm before you get spark - and no deco... lolol

Try a 0000-400-1300... you'll probably like it.

Try a 0000-400-1300... you'll probably like it.

Last edited: