Your 917.353770

I have a very nice running one of those, it is also a Roper 3.7 but is a newer model than the .XXX750 featured in this thread. It's a good saw, and since it has sentimental value to you it's worth whatever effort you put in it. I prefer the 750 style in the Ropers since they seem more compact, less wide/bulky, but that's just my personal bias.

They are very easy to tear down and work on, they also have plastic gas and oil reservoirs, they use the same motor as the 750 with the same crank seals, same piston/rings. I also considered putting a dual adjustable carb on mine, it comes with a Tillotson carb and an RK 23HS rebuild kit will work for it.

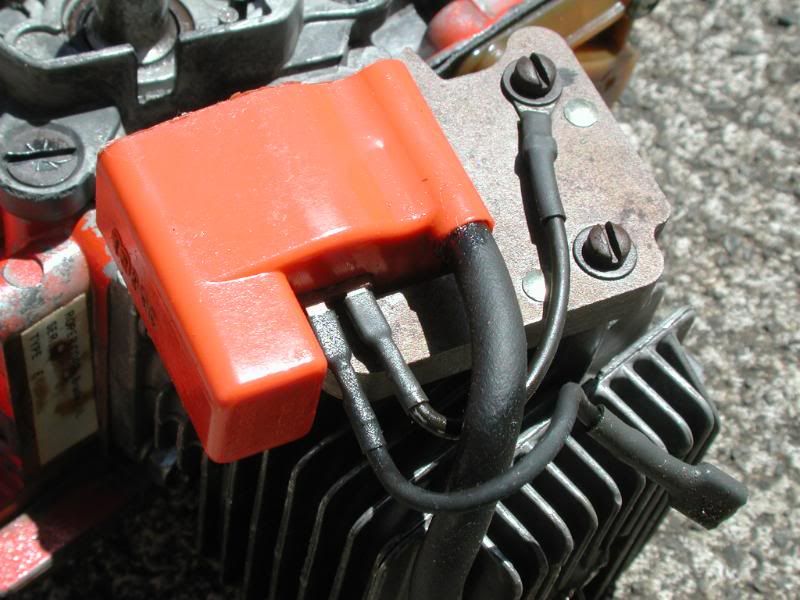

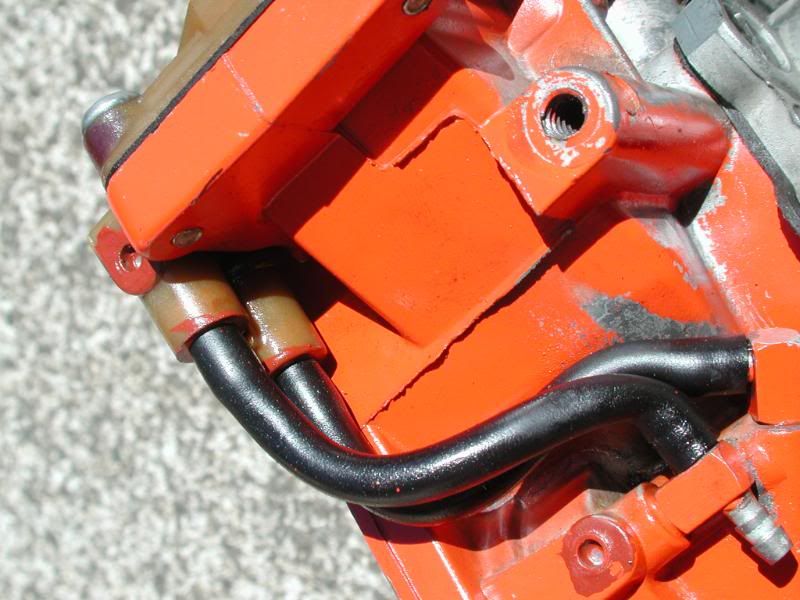

A dual adjustable carb like a Tillotson HS79A would be a carb you could use with this feature, however take the top off your saw--the mechanism of the trigger and configuration of the box would not allow a space for the adjustment screw for the high mix screw. Remember I have one of these saws, I also thought about upgrading exactly like you, but with the parts in hand and the saw on my bench I saw it would not be a beneficial process. That doesn't mean it cannot be done. Look at your saw, find the low speed mix adjustment, then look for the dimple about 1/2" rearwards on the carb body--that's where the High speed mix adjustment would go. You would have to cut off the "screw" so it would clearance the shaft/lever assembly (trigger wire hooks to that) and cut in a new screwdiver slot. To access this for adjustment though, the trigger lock is right in the way, you would need to drill a hole thru the side of the airbox where you could reach this screw to turn it, and come up with a plug to then cover the hole in the airbox so you don't suck debris into your carb thru it. So go back up to the first photo, look at the location of the low speed adjustment screw, and you can see the trigger lock and idle adjustment screw is practically right where the high speed adjustment screw would come, if you did shorten the high speed screw so it would fit behind the trigger lever, and you'd have to have the saw running almost wide open for that to rotate out of the way while you try to come in sideways to try to adjust the screw. Yes, can be done. Is it worth it? Only you will know for sure. I didn't bother to modify mine because of this awkward arrangement in the trigger/trigger lock mechanism. I just put in carb rebuild kit, new rings, new crank seals, sparkplug, gas and oil and ran the you know what out of it. Good luck, and welcome to the forum.