I received the saw last night and started tearing it apart. No ID tag so no way of determining the saws age.

1. The saw has a "black coil" and a previous owner didn't set the gap correctly and the coil rubbed on the flywheel. Can anyone tell me how to test a coil and see if it's still good? Is this one limited to 9600rpm's typically on 3120's?

2. At first glance, the carb has two needles. I haven't cleaned it thoroughly but is this one fully adjustable?

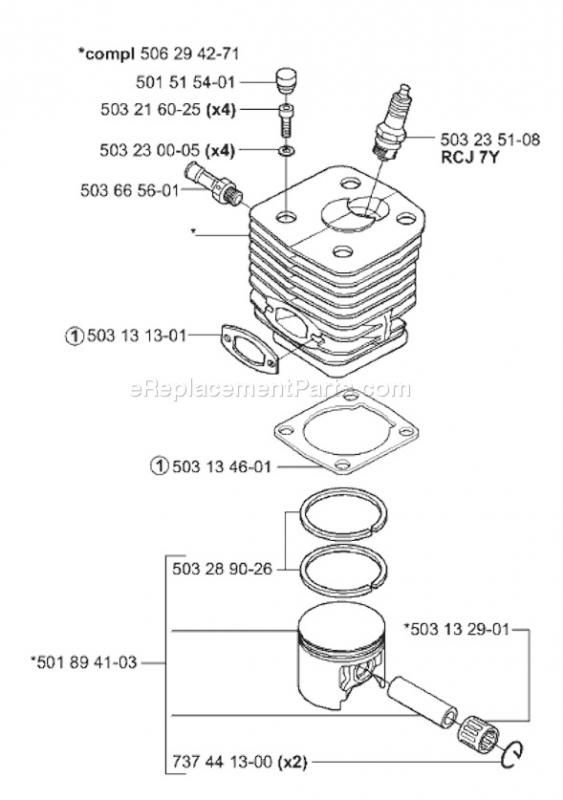

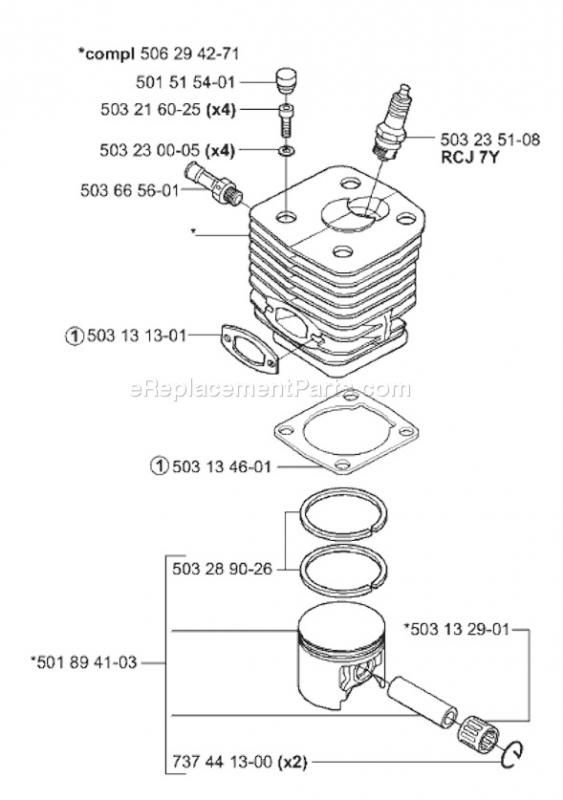

3. I pulled the muffler and the piston was at TDC. Looking through the muffler port, the piston skirt was like new. I thought I would be lucky! Unfortunately, after the crown was visible, I could clearly see it's toast. After pulling the jug, it was confirmed.

4. Now the jug... Cylinder walls look real good. No aluminum transfer but some light scratches on cylinder walls which I think can be had with a little bit of scotch-brite. Top of the cylinder is all banged up however.

What I can't tell is if the jug is OEM or aftermarket. Casting looks good with no defects. Transfers, intake, & exhaust ports are symmetrical. From Husqvarna's IPL's, the images depict "slots" cut into the jug with the muffler bolts inserted while the nuts are at the muffler end.

All aftermarket jugs have threaded castings for muffler bolts and even this OEM unit as well.

http://www.ebay.com/itm/HUSQVARNA-n...838?pt=LH_DefaultDomain_0&hash=item462cdd4ebe

Mastermind's 3120xp build has threaded castings.?

http://i1160.photobucket.com/albums/q498/Mastermind7864/Husqvarna 3120/3120029.jpg