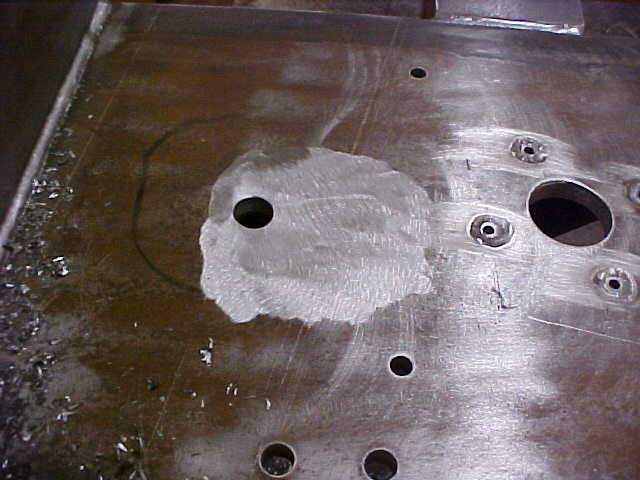

After a lot of measuring I drilled the holes for the hitch receiver. I want to be able to flip the hitch over so the splitter will remain level when using a truck or a tractor. I'll make the hitch a drop for the tractor, turn it 180 degrees and it's a riser. Doing this on the drill press bed keeps everything straight.

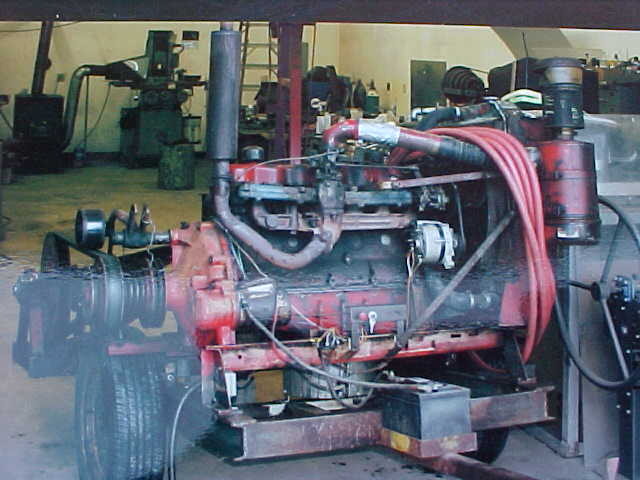

I put it in place and made sure everything was even and put a few tacks on. Check again and start final welding it.

Everything ties together making it a lot stronger. Looks a lot better better now as it comes together. You think of things in your head but you're never completely sure till you see it in real life.

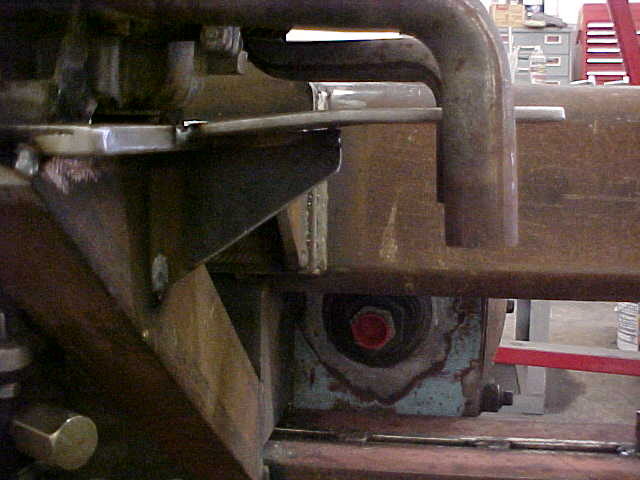

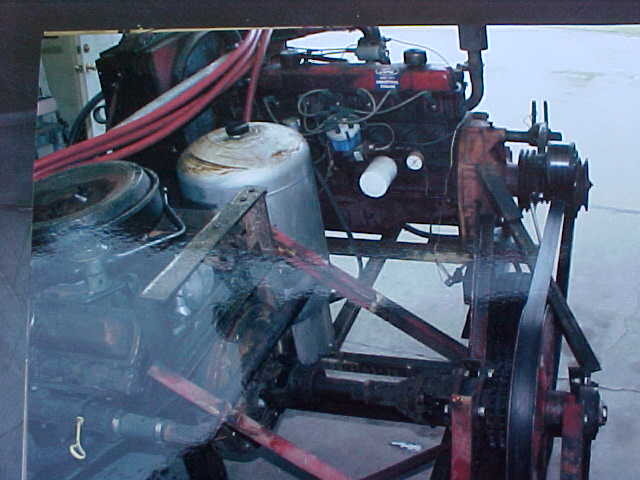

Wanted to put some gussets where the 2 big boxes meet. Cut out some .375 plate and bent it in the press to match the splitter.

One down and a few more to go!

All the gussets done and installed. I'll do the rest of the welds when I disassemble and roll it on it's side.

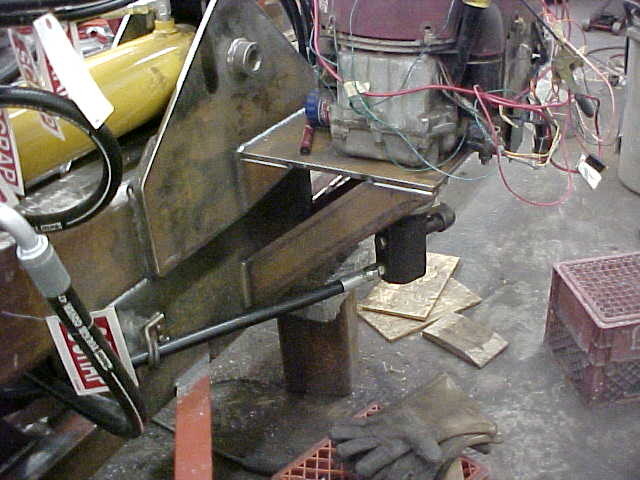

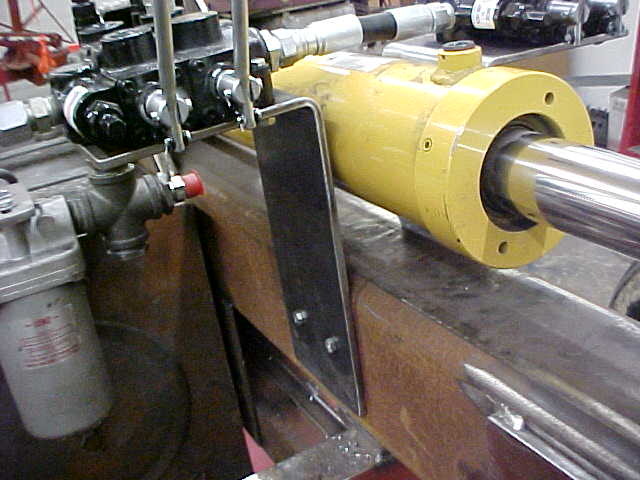

For the valve mounts I just bet up some 3/8" plate that's 6 inches wide. I wanted the valves in a position where you could work them from either side but not be in harms way.

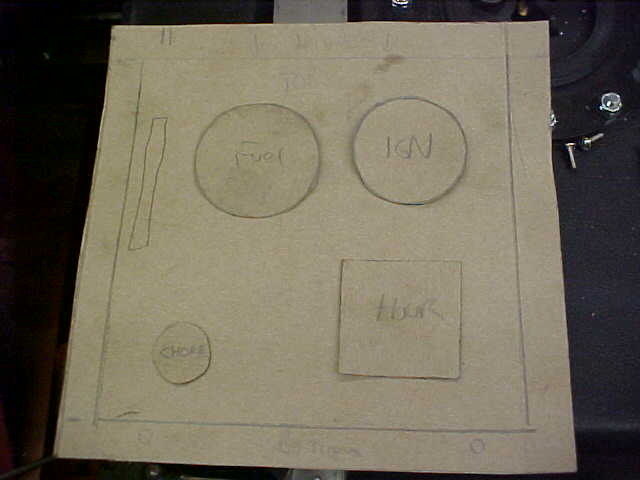

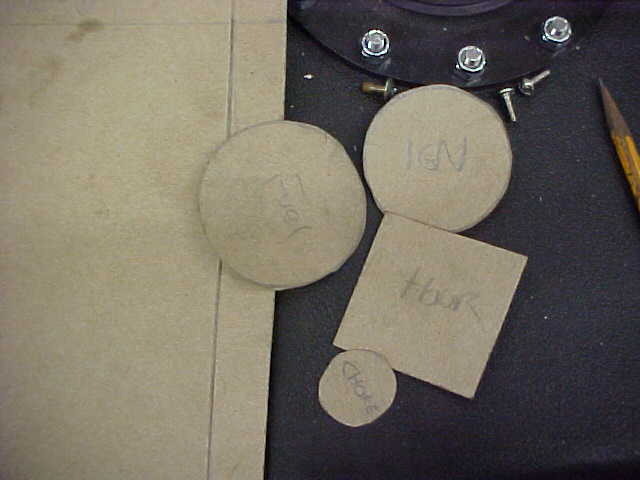

I bolted these on as I know from the past, sometimes you might want to "adjust" things. The layout of the hydraulics is the most mind challenging aspect of this for me. Trying to figure out the position where it will line up is a pain sometimes. I did a drawing of where each line goes to help me out.