they exist for a reason, sure an eye to eye choker works, but its a pain in the ass to use and will fail sooner then later. Or you could pony up the rather small sum to have the right tools for the job, save yourself some ass ache and be a might bit safer at the same time.Well in the logging industry I can see where these different types of chokers can make a big difference but for myself and other firewood people just a simple steel cable with a loop on the end works fine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Choker Cable, or Chain and Choker Hook,,,,, OR,,,,, Bull Dogs!!?? (not the Purina kind!)

- Thread starter SweetMK

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have a set but rarely use them since the invent of the farm tractor and chainsaw. lmao OTYes, they are still used by some folks who log with horses. They're called "log grabs" or log dogs and are traditionally pounded in and pulled out with a "skip hammer". Here is a source for new ones. https://horseloggersupply.com/shop

The nice thing about them is that they don't require you to slide anything underneath the log or roll it over onto a choker. They also don't come loose and fall off if you back up like tongs often do.I have a set but rarely use them since the invent of the farm tractor and chainsaw. lmao OT

Well,, I am going to "try" to make a set of these log dogs,,

I have been watching blacksmith videos FOREVER on YouTube,, I thought I was gonna use charcoal,, but, propane seems easier.

Recently, a couple videos showed the importance of aiming the flame at the part..

I wondered if positioning the part wasn't more important than insulating the forge? The only was to find out,, was to try.

I have had a TurboTorch for 30 years, a couple years ago, I got a "T-6" tip for the torch.

I got it out, and set up the torch outside,,

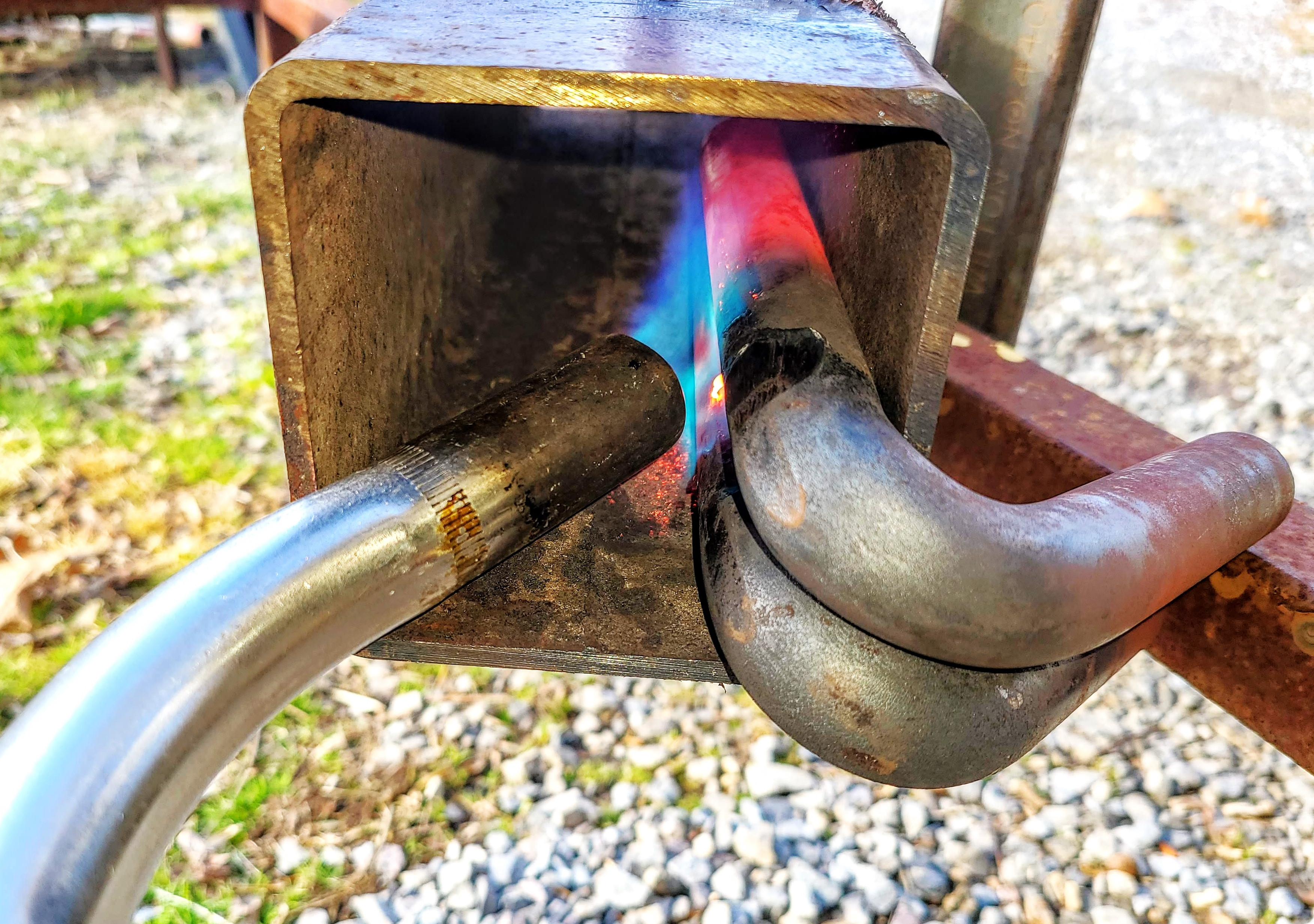

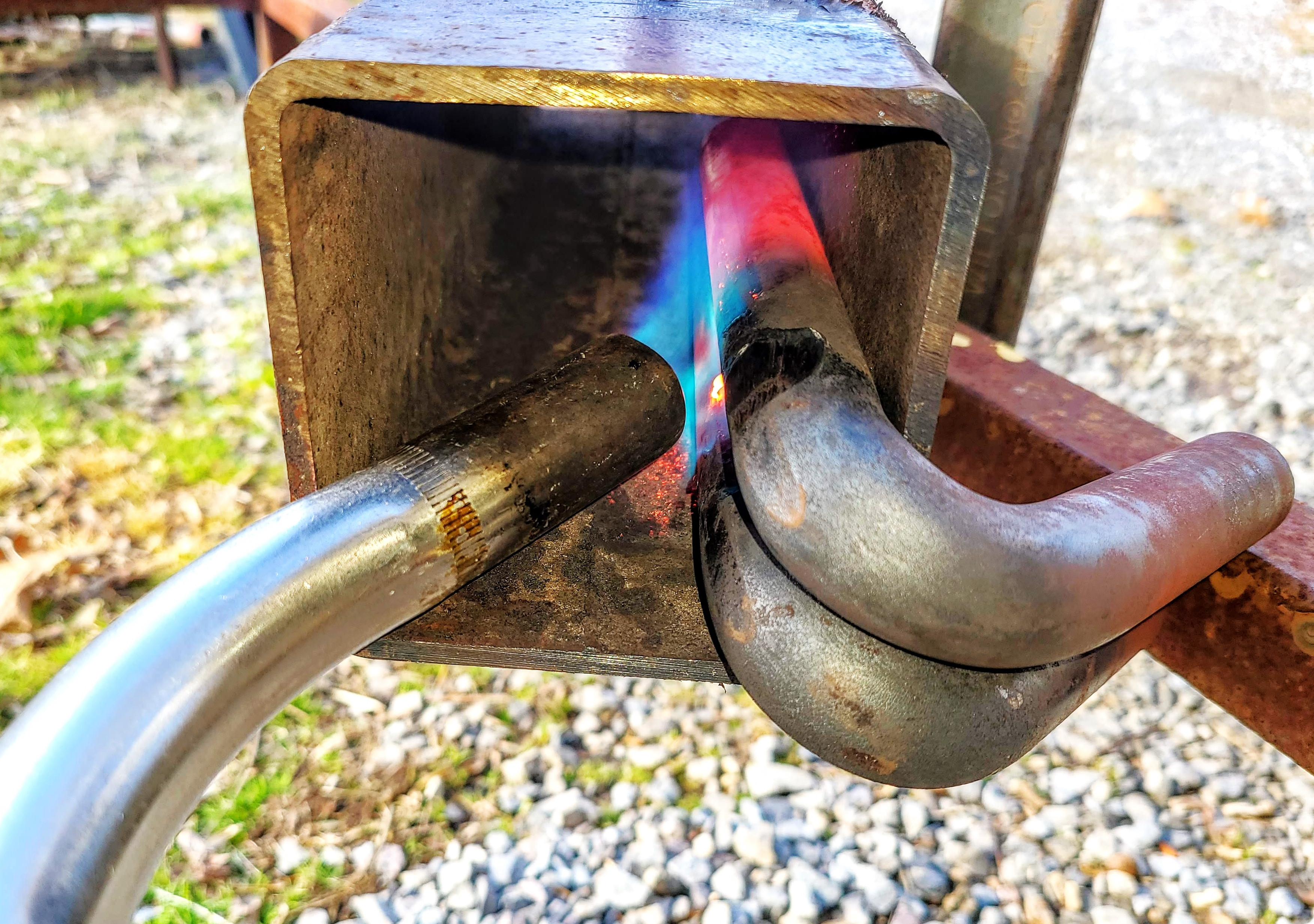

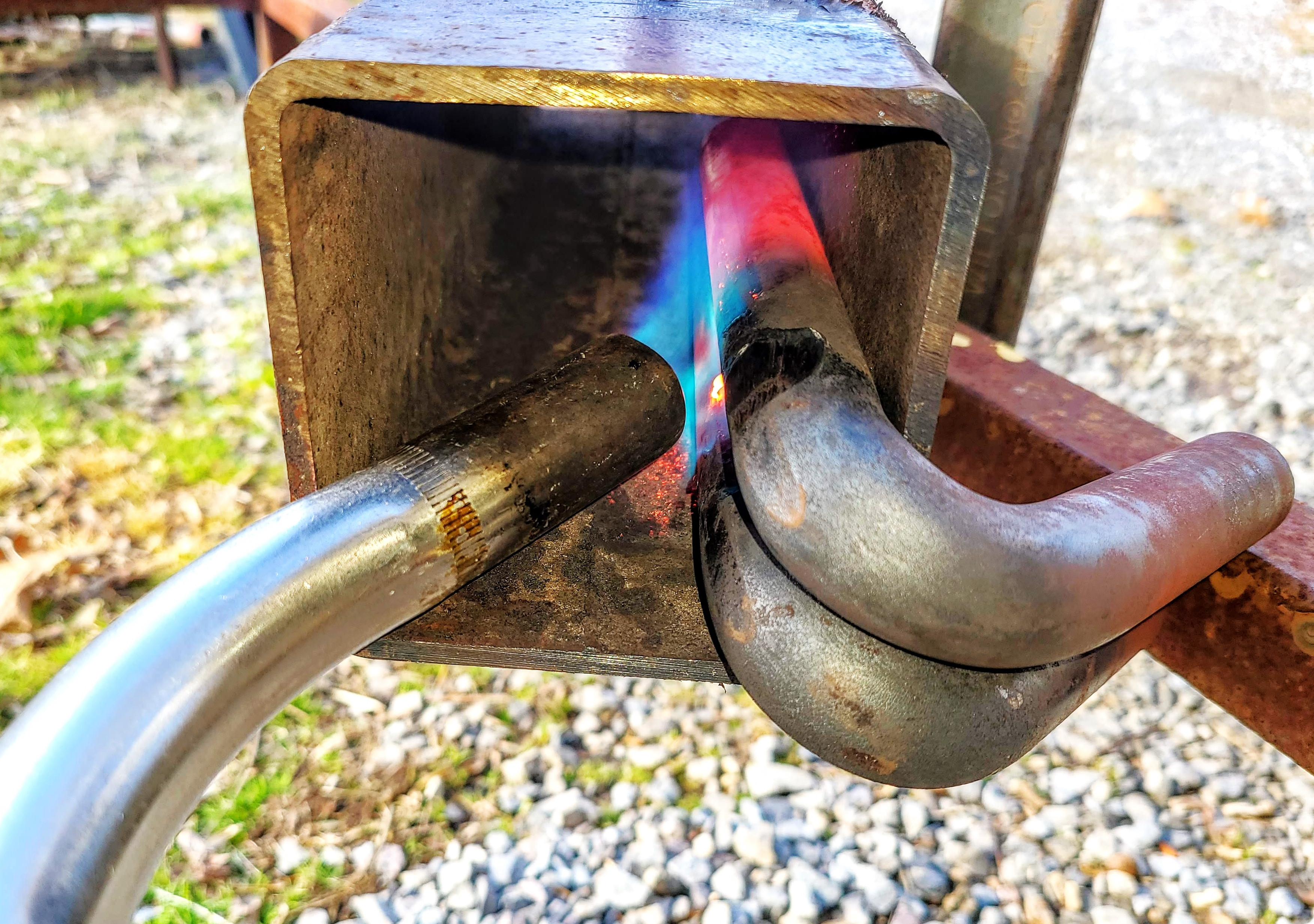

I simply used a leftover scrap of 4X4 inch square tube, with the torch aimed in it.

Two pieces of 1 inch diameter steel round bar were put in the tube, and the torch was aimed in it.

(The day before I took these pics, I had used this torch to bend the bars)

On my first try, I heated one bar at a time,, I had both bars, so I figured I would try heating both.

Well, in about 5 minutes, the steel bars were HOT!!

I was really surprised,, I had tried this before without the piece of square tube,,

after 30 minutes, without the square tube, the piece of bar was barely dull red. the tube helped heating a lot!!

The T-6 tip consumes about 2 pounds of fuel an hour,, so a standard barbeque tank will last ~10 hours.

Here is a pic of my "anvil",, a worn out front wheel off of a 953 CAT,, it does not move when you hit it.

My other "blacksmith" tools,, blacksmith gloves,, blacksmith tongs,, and blacksmith hammer.

After trying the first hammer,, not much was happening,, so I got out an 8# sledge,,

THAT 8# sledge was way too hard to swing one-handed,, then I remembered another hammer I had put a handle on.

The short handle helped,, even though the head must be pretty close to 8#...

After three heating and poundings of each pin I stopped to check my results,,

Mostly, I had lengthened the pins, rather than making them wider,,

I will have to study up on how to make the steel get wider, rather than longer,,,

I will try again, the next day it is not snowing,,,

I have been watching blacksmith videos FOREVER on YouTube,, I thought I was gonna use charcoal,, but, propane seems easier.

Recently, a couple videos showed the importance of aiming the flame at the part..

I wondered if positioning the part wasn't more important than insulating the forge? The only was to find out,, was to try.

I have had a TurboTorch for 30 years, a couple years ago, I got a "T-6" tip for the torch.

I got it out, and set up the torch outside,,

I simply used a leftover scrap of 4X4 inch square tube, with the torch aimed in it.

Two pieces of 1 inch diameter steel round bar were put in the tube, and the torch was aimed in it.

(The day before I took these pics, I had used this torch to bend the bars)

On my first try, I heated one bar at a time,, I had both bars, so I figured I would try heating both.

Well, in about 5 minutes, the steel bars were HOT!!

I was really surprised,, I had tried this before without the piece of square tube,,

after 30 minutes, without the square tube, the piece of bar was barely dull red. the tube helped heating a lot!!

The T-6 tip consumes about 2 pounds of fuel an hour,, so a standard barbeque tank will last ~10 hours.

Here is a pic of my "anvil",, a worn out front wheel off of a 953 CAT,, it does not move when you hit it.

My other "blacksmith" tools,, blacksmith gloves,, blacksmith tongs,, and blacksmith hammer.

After trying the first hammer,, not much was happening,, so I got out an 8# sledge,,

THAT 8# sledge was way too hard to swing one-handed,, then I remembered another hammer I had put a handle on.

The short handle helped,, even though the head must be pretty close to 8#...

After three heating and poundings of each pin I stopped to check my results,,

Mostly, I had lengthened the pins, rather than making them wider,,

I will have to study up on how to make the steel get wider, rather than longer,,,

I will try again, the next day it is not snowing,,,

I resemble that remark, I just broke a chain about an hour ago

You'll need to have these "lips" on the top of them (circled in green), otherwise it'll be a nightmare trying to get them pulled out once they're pounded in and pulled on.Well,, I am going to "try" to make a set of these log dogs,,

Attachments

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

I saw those,, I expect I will have to weld those on,,,You'll need to have these "lips" on the top of them (circled in green), otherwise it'll be a nightmare trying to get them pulled out once they're pounded in and pulled on.

So the "insulation" is partly to protect the structure of the forge, but it also helps with retaining heat and will allow you to get much much higher temps.Well,, I am going to "try" to make a set of these log dogs,,

I have been watching blacksmith videos FOREVER on YouTube,, I thought I was gonna use charcoal,, but, propane seems easier.

Recently, a couple videos showed the importance of aiming the flame at the part..

I wondered if positioning the part wasn't more important than insulating the forge? The only was to find out,, was to try.

I have had a TurboTorch for 30 years, a couple years ago, I got a "T-6" tip for the torch.

I got it out, and set up the torch outside,,

I simply used a leftover scrap of 4X4 inch square tube, with the torch aimed in it.

Two pieces of 1 inch diameter steel round bar were put in the tube, and the torch was aimed in it.

(The day before I took these pics, I had used this torch to bend the bars)

On my first try, I heated one bar at a time,, I had both bars, so I figured I would try heating both.

Well, in about 5 minutes, the steel bars were HOT!!

I was really surprised,, I had tried this before without the piece of square tube,,

after 30 minutes, without the square tube, the piece of bar was barely dull red. the tube helped heating a lot!!

The T-6 tip consumes about 2 pounds of fuel an hour,, so a standard barbeque tank will last ~10 hours.

Here is a pic of my "anvil",, a worn out front wheel off of a 953 CAT,, it does not move when you hit it.

My other "blacksmith" tools,, blacksmith gloves,, blacksmith tongs,, and blacksmith hammer.

After trying the first hammer,, not much was happening,, so I got out an 8# sledge,,

THAT 8# sledge was way too hard to swing one-handed,, then I remembered another hammer I had put a handle on.

The short handle helped,, even though the head must be pretty close to 8#...

After three heating and poundings of each pin I stopped to check my results,,

Mostly, I had lengthened the pins, rather than making them wider,,

I will have to study up on how to make the steel get wider, rather than longer,,,

I will try again, the next day it is not snowing,,,

Couple tips, if you plan on persuing anymore smithing work, get at least a flat anvil, and place it just below knuckle height while standing comfortably, your wrist and back will thank you.

Stop wearing gloves at least on your hammer hand, you may get burned, (you will anyways) but you won't be working as hard to hang on to the hammer, and will have more accuracy, as well as more control of tongs/material etc. Besides if its so hot that you need gloves to hang on to it, they will only help for a minute or less, then they heat the gloves beyond use anyway.

IF you're using high carbon steel, work it when its red, but don't heat until yellow unless you plan on welding it, it looses too much carbon at yellow, and will become brittle if worked cold, Don't quench it until you need it hardened, let it cool slowly under welding blankets or in dry sand if possible.

As for hardening, most modern knife makers will insist on using oil... there is literally no need for this if you don't overheat before quenching, it needs to be cherry red, no more. if its so hard as to be brittle, then temper it as I strongly suggest doing for any sort of log dog/grapple as they get shock loaded more then anything.

As for hammering tapers, work the piece on two sides so it gets thinner evenly, you flatten one side then attempt to do the other it will just taco, better to make a square taper, then round it later if desired. Start from the end and work your way up the material. Also better to create the taper while the material is straight and easy to turn, then put the bend in afterwards, also makes placing the bend accurately easier.

Now that you mention it,, I do have a flat item,, and it probably weighs 5X as much as the 953 wheel,,

It is the counterweight off of a John Deere tracked loader,, (the piece behind it is the bracket to mount the weight to the machines frame.)

It is probably ~3,000 pounds,, ?? THAT should not move if I hit it,,,

I still have to figure out how to make the part get wider, rather than longer,,,,,,,,,,

It is the counterweight off of a John Deere tracked loader,, (the piece behind it is the bracket to mount the weight to the machines frame.)

It is probably ~3,000 pounds,, ?? THAT should not move if I hit it,,,

I still have to figure out how to make the part get wider, rather than longer,,,,,,,,,,

It is interesting to see the comments about the different types of chokers. It does not matter of you use chain, cable,rope, or something else. They all have their place where they work best. They all can and will fail. They all can and will cause injury and damage when they fail. It will not be everytime they fail but it will happen eventually. Chains will break and can send pieces flying. Just ask any farmer if he has had one come.through the cab window. Cables will break and whip. It is funny how many folks think rope is safe. Thankfully to date the worst injury I have personally seen is a broken leg and that was from a broken rope. Now that was a barge rope on a 15 barge tow 30 years ago but it was bad. Everyone had their preference. If they all did not work then no company would make them.

to make stuff wider, you need to use the cross pien, or preferably but much hard to find a straight pien hammer, the "black smith" hammer with the tapered side, use that to strike with the wedge shape forcing material in the direction you want the work piece to grow, it can be done with a cross pien, but its a PITA, if you had a fuller set its even easier, but not having a proper anvil... I'm guessing you don't have a fuller set either (hell I don't and I have several anvils lol) You can also upset the material by hammering on the end of it... but its not easy, and its even more work then it looks.Now that you mention it,, I do have a flat item,, and it probably weighs 5X as much as the 953 wheel,,

It is the counterweight off of a John Deere tracked loader,, (the piece behind it is the bracket to mount the weight to the machines frame.)

It is probably ~3,000 pounds,, ?? THAT should not move if I hit it,,,

I still have to figure out how to make the part get wider, rather than longer,,,,,,,,,,

I suggest getting a hand full of silly putty or modeling clay and "practice" forming it into shapes using your fangers as "hammers" or even going so far as to use something that resembles a small hammer to shape it, it will give you a fairly solid idea of how the metal moves under impact, in reality they react very similarly, though the steel will take much more effort to move.

you are right everything fails, also a pretty major reason why a person should use the proper and best tool for the job. log chokers are damned good tools, and will work far better then any of the "tried and true" half measures such as tow chains, eye to eye chokers, single eye with a shackle/hook/pipe choker, I guarantee all of them will fail long before a log choker doing the same job.It is interesting to see the comments about the different types of chokers. It does not matter of you use chain, cable,rope, or something else. They all have their place where they work best. They all can and will fail. They all can and will cause injury and damage when they fail. It will not be everytime they fail but it will happen eventually. Chains will break and can send pieces flying. Just ask any farmer if he has had one come.through the cab window. Cables will break and whip. It is funny how many folks think rope is safe. Thankfully to date the worst injury I have personally seen is a broken leg and that was from a broken rope. Now that was a barge rope on a 15 barge tow 30 years ago but it was bad. Everyone had their preference. If they all did not work then no company would make them.

As for cables whipping about, its largely old wifes tails, yes there is stored energy in cable, but not nearly as much in say the tires supporting said cable, the giant tree acting as a bow stave etc, where as rope that so many in the industry claim as being safer has a much higher elasticity compared to cable and therefore much much more stored energy. Feel free to look it up for yourself, you might be surprised.

wait... a cross pien does work better for widening material...

My apologies, sometimes hard to see this stuff in muh head, straigh pien for making thangs longer... like knives out of stupid thick metal.

My apologies, sometimes hard to see this stuff in muh head, straigh pien for making thangs longer... like knives out of stupid thick metal.

to make stuff wider, you need to use the cross pien, or preferably but much hard to find a straight pien hammer, the "black smith" hammer with the tapered side, use that to strike with the wedge shape forcing material in the direction you want the work piece to grow, it can be done with a cross pien, but its a PITA, if you had a fuller set its even easier, but not having a proper anvil... I'm guessing you don't have a fuller set either (hell I don't and I have several anvils lol) You can also upset the material by hammering on the end of it... but its not easy, and its even more work then it looks.

I suggest getting a hand full of silly putty or modeling clay and "practice" forming it into shapes using your fangers as "hammers" or even going so far as to use something that resembles a small hammer to shape it, it will give you a fairly solid idea of how the metal moves under impact, in reality they react very similarly, though the steel will take much more effort to move.

you are right everything fails, also a pretty major reason why a person should use the proper and best tool for the job. log chokers are damned good tools, and will work far better then any of the "tried and true" half measures such as tow chains, eye to eye chokers, single eye with a shackle/hook/pipe choker, I guarantee all of them will fail long before a log choker doing the same job.

As for cables whipping about, its largely old wifes tails, yes there is stored energy in cable, but not nearly as much in say the tires supporting said cable, the giant tree acting as a bow stave etc, where as rope that so many in the industry claim as being safer has a much higher elasticity compared to cable and therefore much much more stored energy. Feel free to look it up for yourself, you might be surprised.

One might be surprised how long it sometimes takes for a hammer blow to soak in to a chunk of steel . it is not entirely immediate. (circle saw blades and tension)wait... a cross pien does work better for widening material...

My apologies, sometimes hard to see this stuff in muh head, straigh pien for making thangs longer... like knives out of stupid thick metal.

Probably,, about as long as new concepts take to soak into my thoughts,, LOL!!One might be surprised how long it sometimes takes for a hammer blow to soak in to a chunk of steel . it is not entirely immediate. (circle saw blades and tension)

I am a torch, saw, welder kind of guy,,

this hammerin' steel is sort of new to me,,,,,,,,,,,,

There are two reasons that some things are made besides that they work well for their intended job. Those two things are cost and institutional inbreeding. Some things are made and sold because they're cheap to make and cheap to buy, not because they work particularly well. There are also things that are made and sold because many folks within certain industries or regions have not had enough exposure to ideas and techniques outside of that industry or region.If they all did not work then no company would make them.

@SweetMK, assuming you aren’t going to be using heavy equipment then buy a 8’ long 1/2” choker with 3 links of 3/8” chain on the end instead of a loop. It will make you life easier if you need to extend your reach to the stem and/or if you don’t have a suitable rounded attachment point for a looped end choker. $50 well spent. You won’t break the 3 link chain with a pickup truck or compact tractor.

Ron

Ron

That’s it. Don’t forget to wear gloves as after a few uses it will develop broken strands that will get you.

Ron

Ron

It is interesting to see the comments about the different types of chokers. It does not matter of you use chain, cable,rope, or something else. They all have their place where they work best. They all can and will fail. They all can and will cause injury and damage when they fail. It will not be everytime they fail but it will happen eventually. Chains will break and can send pieces flying. Just ask any farmer if he has had one come.through the cab window. Cables will break and whip. It is funny how many folks think rope is safe. Thankfully to date the worst injury I have personally seen is a broken leg and that was from a broken rope. Now that was a barge rope on a 15 barge tow 30 years ago but it was bad. Everyone had their preference. If they all did not work then no company would make them.

So… The crux of your argument is that while different tools are meant for different uses, it doesn’t matter what is used for what purpose because they all fail?

Why not make an effort to limit the probability of failure? That’s the entire purpose of having these different tools.

@SweetMK-Congratulations on getting a tool that should make like a lot easier. Enjoy it, and use it for its intended purpose.

As tractors got bigger on the farm,, we ended up lengthening a couple chains, to the point that they would no longer bend,,

At that point, my BIL went to Richmond VA (in 1973) and bought two chains that are 25 feet long, and cost $100 each.

They still use the two chains, and they are as good as the day they were purchased..

I checked the inflation, from then, to now,, those chains cost $633 each, in todays dollars.

I guess that is why they still survive,, even though the horsepower has grown on the farm, considerably.

At that point, my BIL went to Richmond VA (in 1973) and bought two chains that are 25 feet long, and cost $100 each.

They still use the two chains, and they are as good as the day they were purchased..

I checked the inflation, from then, to now,, those chains cost $633 each, in todays dollars.

I guess that is why they still survive,, even though the horsepower has grown on the farm, considerably.

Similar threads

- Replies

- 30

- Views

- 4K