The problem with your numbers is that the 22gpm pump unloads at around 500psi and is only pumping 6 or 7gpm at high pressure. The lower flows and higher pressures will work fine with the smaller engine. Now if that pump was to make full pressure at 22gpm, then your suggestions would be closer to correct. Also. a lot of two stage pumps do have the capability to adjust the unloading pressure, but I don't think any of them will allow the full flow at the high pressure adjustment.First 22gpm needs aboit 19hp at 3000psi. If your running a 2000psi system your 11hp would be the smallest I'd reccomend. I currently have a 16gpm on a 9hp engine running 3000psi it's about at its limit. Your rule of thumb is 1hp per 1gpm @1500 psi. As these are 2 stage pumps you can half the equation. So the math comes out to just over 38hp for full flow @rated psi. Half that for a 2 stage pump give you about 19hp.

Also have you talked to any local weld shops about a tank? I have a 10gallon tank on my splitter and it cos $30.00 for my local shop to cut and bend the steel for me. All I had to do was weld it up and paint it, and install my fittings/ suction screen in the tank. Wouldnt hurt to call around and ask.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cistom Splitter Build.

- Thread starter 2broke2ride

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I knew they were 2 stage, I just assumed they were like a tandom pump. I worked heavy duty diesel for years and these splitter pumps always were a bit odd to me. Never came across anything like used like it. Thanks for explaining it, makes sense now.

A two stage pump is sorta like a tandem, it is two pumps in one. The unloader valve is internal in a two stage. If a tandem pump is being used in a high/ low two stage setup, the unloader valve will be external. A tandem setup as a high/low has a few advantages, For one I think the biggest two stage wood splitter pump on the market is a 28gpm. Using a tandem, you can mix and match and get 100gpm+ if you want and need it. Usually a tandem setup is used to supply two separate oil flows at max pressure to two separate operations. The two stage is usually used when hp requirements and cost make running high flows and high pressure not cost effective. Its sort of a compromise between high power and high speed. You get both, just not at the same time.I knew they were 2 stage, I just assumed they were like a tandom pump. I worked heavy duty diesel for years and these splitter pumps always were a bit odd to me. Never came across anything like used like it. Thanks for explaining it, makes sense now.

medalist

ArboristSite Operative

As a thought golf course turf equipment all have hydraulic tanks and a good source for small diesel engines.

Find an equipment wholesaler or find what you might need in the local course boneyard.

Find an equipment wholesaler or find what you might need in the local course boneyard.

Another thing I did on my tank was lay a large magnet right in front of the suction port on the inside, I figured it was cheap insurance.

Fatherwheels

Addicted to ArboristSite

Why not use two rams mounted like a double barrel gun, one top of the other,

with a platform between them to rest the top log on,

that would split two logs beside each other where you can re locate them

for the next split, that would speed up splitting,

or a double acting ram that would split on the way back while you rotate the

first log to split it smaller, one end of the ram coming in from splitting

as the other end goes out to split.

with a platform between them to rest the top log on,

that would split two logs beside each other where you can re locate them

for the next split, that would speed up splitting,

or a double acting ram that would split on the way back while you rotate the

first log to split it smaller, one end of the ram coming in from splitting

as the other end goes out to split.

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

- Joined

- Jul 20, 2014

- Messages

- 1,882

- Reaction score

- 2,527

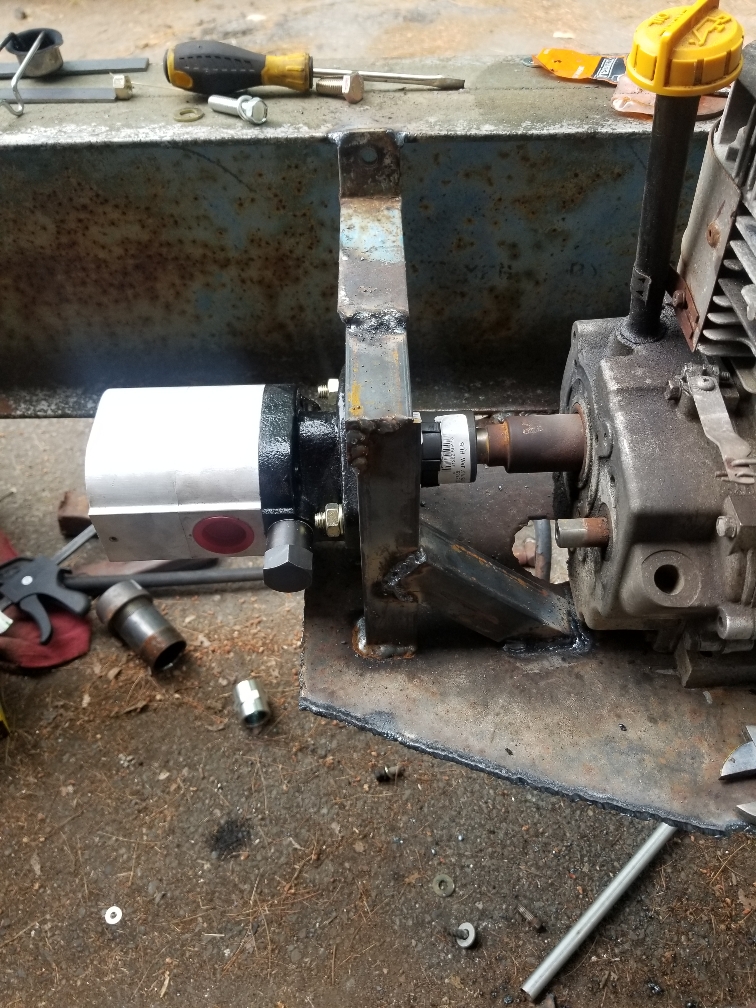

I got the pump mounted up today and started on the mount for the valve.

Sent from my SM-G950U using Tapatalk

Sent from my SM-G950U using Tapatalk

I don't think coating the interior of hydraulic tanks is a good idea, any of that coating comes off and it goes through your tight clearance valves.

I have repurposed a pile of hydraulic tanks and they are never rusty inside, because they are sloshing with oil and if sized correctly get warm enough with use to vaporize the water out of the oil.

I have repurposed a pile of hydraulic tanks and they are never rusty inside, because they are sloshing with oil and if sized correctly get warm enough with use to vaporize the water out of the oil.

medalist

ArboristSite Operative

Another source to consider is Bailey Sales.

https://www.baileyhydraulics.com/I've purchased quite a few items from them in the past.

Also, for hardware or stuff you need but can't get locally I'd suggest McMaster Carr. Like WW Grainger but more industrial and great shipping...I could order at 3pm and have it delivered normal UPS the next morning from Atlanta. Beats going to the store and hoping they have it.

https://www.mcmaster.com/

https://www.baileyhydraulics.com/I've purchased quite a few items from them in the past.

Also, for hardware or stuff you need but can't get locally I'd suggest McMaster Carr. Like WW Grainger but more industrial and great shipping...I could order at 3pm and have it delivered normal UPS the next morning from Atlanta. Beats going to the store and hoping they have it.

https://www.mcmaster.com/

- Joined

- Jan 14, 2002

- Messages

- 4,800

- Reaction score

- 12,596

- Location

- North of Goderich, Ontario, Canada

- Joined

- Jul 20, 2014

- Messages

- 1,882

- Reaction score

- 2,527

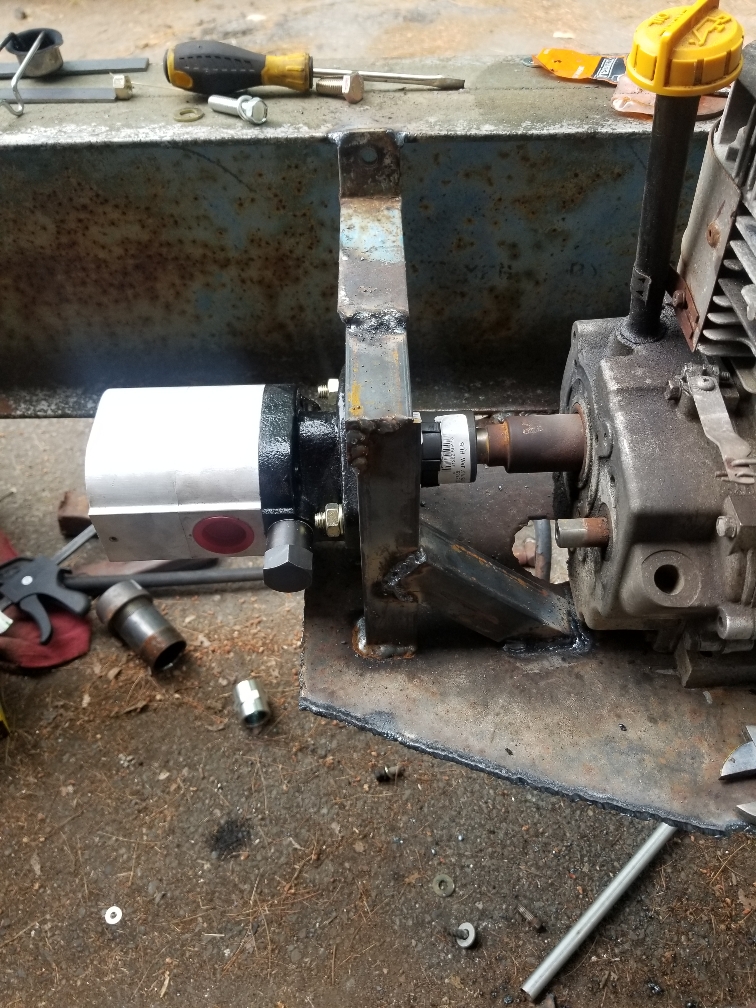

I got the hydraulic filter, and the valve mounted. Reinforced the push block with an old plow cutting edge. Waiting on the tank from my buddy, then I will get that mounted, take everything back off, and paint it.

Sent from my SM-G950U using Tapatalk

Sent from my SM-G950U using Tapatalk

I have the same pump on my splitter And run it with a 16 hp Honda and have never witnessed it Changing stages in the 5 or so years since I built the splitter. I haven’t found something it wouldn’t split yet so I’m not messing with it. I run a 5” bore cylinder with a 4 way 95 percent of the time. I’ve never timed the cycle time but it’s faster than most other splitters i have seen

We used to send all kinds of tanks out to get coated. From diesel to hydraulic. Cant honestly say there was ever a issue with the coating coming off, ymmv of course. The stuff I mentioned is what I have used at home with great success.I don't think coating the interior of hydraulic tanks is a good idea, any of that coating comes off and it goes through your tight clearance valves.

I have repurposed a pile of hydraulic tanks and they are never rusty inside, because they are sloshing with oil and if sized correctly get warm enough with use to vaporize the water out of the oil.

A few things worthy of concern that might be some thing to include. My current setup uses heavy wall tubing both as reservoir and for cooling purposes instead of an I Beam. One could always weld some square or round tubing along the I beam for cooling. On warm days my hydraulics get so hot it will burn your hand so had to find ways to dissipate heat. I also incorporated suspension for bumpy roads, but some do not have crazy roads like I have. The pusher needs to be at least one foot long for knotty wood helps reduce twisting. I also grease and pour a little oil on my slide continously for a longer life. There is a way to eliminate bolts on the pusher too. Of course if one is using less that 22 GPM heat might not be such an important issue. Thanks

Chris moss

ArboristSite Member

Looks great , i have a 27 ton troy built splitter I need to rebuild, it has a 9.5 gpm pump on it now with a honda 160 motor and want to speed it up , i have a new bigger motor , just need thr pump and valve , maybe new lines not sure or new cyl since its a 4.5 in cyl not sure how big the ram in the cyl isI made my tank out of a piece of diamond plate that I proped under the toung of my lawn roller and drove forward so it rolled it into a circle. More tear drop shaped. I’ve been known to improvise View attachment 840709View attachment 840710

- Joined

- Jul 20, 2014

- Messages

- 1,882

- Reaction score

- 2,527

Ok guys, it been a while. As was discussed earlier and as I had feared, I don't have enough horsepower with the 10hp motor.

That being said, has anyone run one of these motors? Great reviews ant the only thing that seems to be different between this and the harbor freight motor is electric start that I don't care about and almost $100.

https://www.amazon.com/dp/B07SG14141/ref=cm_sw_r_cp_apa_i_qWmuFb5QFG4XW

Sent from my SM-G981U using Tapatalk

That being said, has anyone run one of these motors? Great reviews ant the only thing that seems to be different between this and the harbor freight motor is electric start that I don't care about and almost $100.

https://www.amazon.com/dp/B07SG14141/ref=cm_sw_r_cp_apa_i_qWmuFb5QFG4XW

Sent from my SM-G981U using Tapatalk

Ok guys, it been a while. As was discussed earlier and as I had feared, I don't have enough horsepower with the 10hp motor. That being said, has anyone run one of these motors? Great reviews ant the only thing that seems to be different between this and the harbor freight motor is electric start that I don't care about and almost $100. https://www.amazon.com/dp/B07SG14141/ref=cm_sw_r_cp_apa_i_qWmuFb5QFG4XWSent from my SM-G981U using Tapatalk

Briggs, Tecumseh, Kohler, and Honda build decent motors for a decent price. Pretty much all other motors are clones so take your pick. You need from 15 to 18 HP motor to be comfortable with the load you are asking it to bear. I have had the same luck with after market motors as others. Finding parts for most motors is tough and it is not worth while to fix motors as it is much better to replace than to spend an after noon replacing a carburetor. I hate to thrown good motors away, but that is the way it is. Thanks

- Joined

- Jul 20, 2014

- Messages

- 1,882

- Reaction score

- 2,527

The company I bought the pump from, when I bought the pump, there specs said 10hp minimum, 11hp suggested. They have since changed the specs to say minimum required horsepower is 11.75.Briggs, Tecumseh, Kohler, and Honda build decent motors for a decent price. Pretty much all other motors are clones so take your pick. You need from 15 to 18 HP motor to be comfortable with the load you are asking it to bear. I have had the same luck with after market motors as others. Finding parts for most motors is tough and it is not worth while to fix motors as it is much better to replace than to spend an after noon replacing a carburetor. I hate to thrown good motors away, but that is the way it is. Thanks

Do you think this engine will be up to the task? I honestly can't really afford anything better. I've sunk a ton of money into this project already.

Sent from my SM-G981U using Tapatalk

ChoppyChoppy

Tree Freak

Ok guys, it been a while. As was discussed earlier and as I had feared, I don't have enough horsepower with the 10hp motor.

That being said, has anyone run one of these motors? Great reviews ant the only thing that seems to be different between this and the harbor freight motor is electric start that I don't care about and almost $100.

https://www.amazon.com/dp/B07SG14141/ref=cm_sw_r_cp_apa_i_qWmuFb5QFG4XW

Sent from my SM-G981U using Tapatalk

What pump are you running?

Motor or engine? You say 10hp motor, but the link is to a 15hp engine. IE... is this an electric or gas powered splitter?

Disregard... I just realized there was another page with the info.

Roughly 1hp per 1gpm @ 1500psi

At 22gpm, you'll be pretty well maxing out the engine at 800psi.

Similar threads

- Replies

- 36

- Views

- 2K

- Replies

- 12

- Views

- 685

- Replies

- 9

- Views

- 395

- Replies

- 42

- Views

- 2K