Now I'll start on the lifting system. Had a coupon so I bought a 20 inch stroke 8 ton jack for $50.00. Hoped this one would work on it's side but no dice. Some brands do others don't so I'll have to do some tear down and see what is up.... or why it won't go up!

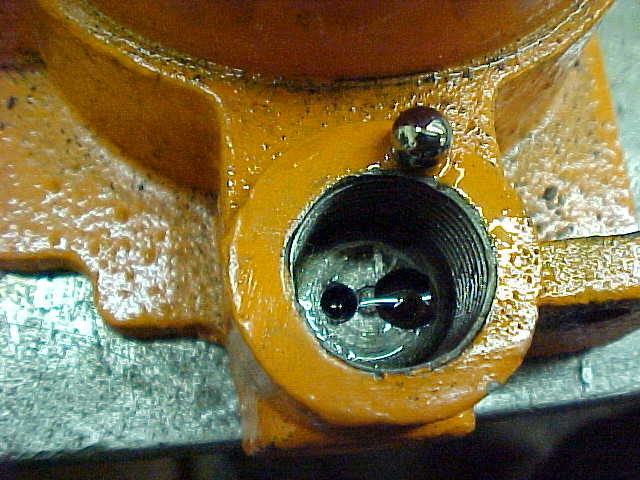

Took off the piston/plunger and there were 2 passages. One for incoming, the other for outgoing. One check valve on incoming side and they use a washer to hold the ball in place. Gravity seats it after sealed piston draws fluid in by vacuum preventing the fluid from going back. BINGO!

Here's a close up. First time tearing into one of these and I can see why it doesn't work on it's side now. I just need the ball to seat after the fluid is drawn in.

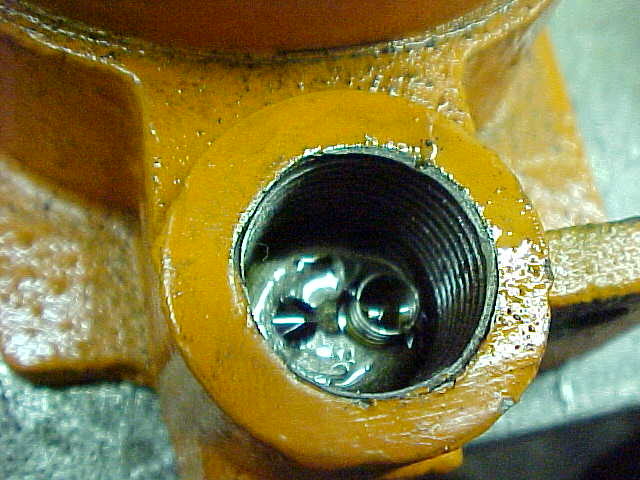

I'll try adding a real light pressure spring between the ball and washer. Found a spring in the junk drawer that looks to be what I need.

Fit perfect in the hole and is right for the ball as well. So far so good. Put it all back together and it works! Tested it with a chain wrapped around and develops pressure just fine. He shoots, he scores.

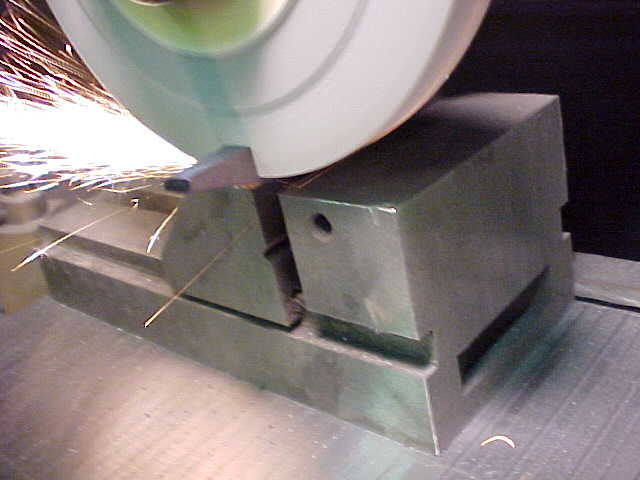

With the jack looking like it'll work I'll start on the pivot mounts for it. Got a couple 1/2" scraps off the pile and laid out some lines. Double cheater bars here doing the cutting.

Rounded the corners using an old patter from another project. saves me time as I'm not that good at freehanding things.

Got the 2 sides of the lower mount the same by touching up with the angle grinder. Then, While still together I drilled the .875 hole for the pivot pin. Cleaned and beveled the weld are. Next is the lower mount for the jack.

Back to the scrap pile again. Cut what I needed with the surface grinder and this is all the pieces. Basically going to trap it in position with one bolt so I can use the jack for other stuff if needed.

nice work as usual

nice work as usual