Sawdustmaker

Addicted to ArboristSite

Help please, i am lost. i am looking for a place to post pics of a new cylinder that i have that may be of interest to some of y'all...

i did not pull this of a saw because of perinoia.

I just got this in the mail. Note the chamfering.

Can you guess what it is?

Does a reduction in quality by other companies make this cylinder better? No it doesn't. That's why I don't "curve" grades in the classes I teach. In a class full of *******, the smartest retard is not an A student. In a class full of geniuses, the poorest performer is not an F student.

I tried a eulogy 4 pages (68 posts) earlier, but to no avail.

If only Dr. Kevorkian would return my calls...

Ed,

Just pray you "significant other" doesn't call Dr. K. Let your "significant other" that dr. joat is close and available for a small fee.

I'll negotiate for that 076 in lieu of fee at the funeral,

dr. joat

Sorry Joat...it wouldn't work out. She's a bit of a "do it yourself"er herself.

She also shares my appreciation for quality, so you probably wouldn't make her list if she was looking for a professional.

One of my "strategies" is to try to get people focus on the issue. We are talking about the cylinder in the pictures that is a piece of crap relative to other Stihl cylinders. Based on reports of others, it looks like it might be a trend and not an anomaly.

Does a reduction in quality by other companies make this cylinder better? No it doesn't. That's why I don't "curve" grades in the classes I teach. In a class full of *******, the smartest retard is not an A student. In a class full of geniuses, the poorest performer is not an F student.

Does a statement that Toyota makes bad master cylinders add anything to the discussion? No. It is another distraction, and an unsubstantiated distraction at that. Even with pictures, however, it still would be a distraction. This person made the master cylinders, and therefore was part of Toyota's quality control. Are you suggesting he was putting out dangerous products? If so, your issue is with him and not me.

If you want to separate yourself from the blind supporters, take your own advice and read my posts on this thread before labeling me as a basher/piler. I do have fun with Stihl owners (and Chevy owners) on other threads, but it is just that...fun. It continues to be fun if the level of quality is the same. As I've stated numerous times in this thread, it isn't fun here, it is just sad. My posts are based on disappointment, not brand fidelity. If you can't tell the difference, then I can't help you understand.

Does the comment, do you pump your brakes 12k per minute add anything of substance to the conversation?

How do you acknowledge me as a blind supporter vs you being a blind supporter yourself?

What more do you have to offer except minimal technical and scientific evidence that says the cylinder portrayed is detrimental to the performance of the product in question? Have I tore down more of the manufacturer's saws in question along with husqvarna saws then you have? I feel pretty confident saying yes....do you feel otherwise?

What is the purpose of taking a picture of your saws in your signature line? Is it to drive home the fact that you and your wife appreciate high quality products? If so, I think you may be lacking the highest quality saws, even in the manufacturer's displacement levels you have represented.

I get a kick out of your comment "It isn't fun here"...what are you referring to? It must be fun here for you, since you seem to frequent the site quite often throughout the day?

How can you say the guy that says he is making the master cylinders for toyota is anymore unsubstantiated than your comments? At least he is involved in the manufacturing process ....what are you involved in the "criticism department"?

I also like your comment....about the class full of *******...I have no idea what level of education you teach. However, if you do teach at the college level, I personally learned the most from a computer logics class that was graded on a curve that the average 'A' was a mid 50's or less percentile.

I also think that if your teaching at a college level and you have a class full of *******, it may have to do with the quality of teaching of the teacher.

Ed,

10-4. It's so hard to establish yourself these days.

ole joat

SDM,

I think it is probably a mahle 44.7 mm 260 cylinder? Do I get the $10 Thall was offering in the other thread?

Take care,

Brad

Maybe I'm reading the wrong things, but this:

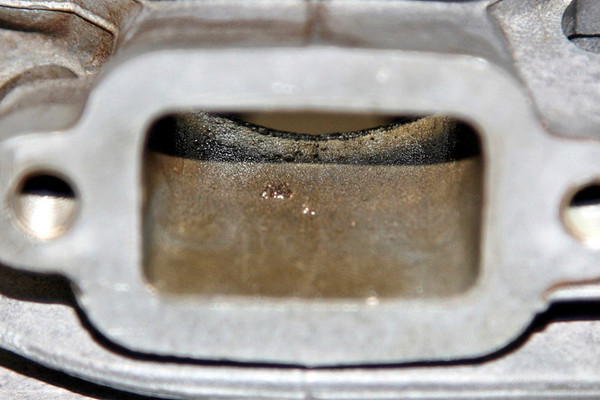

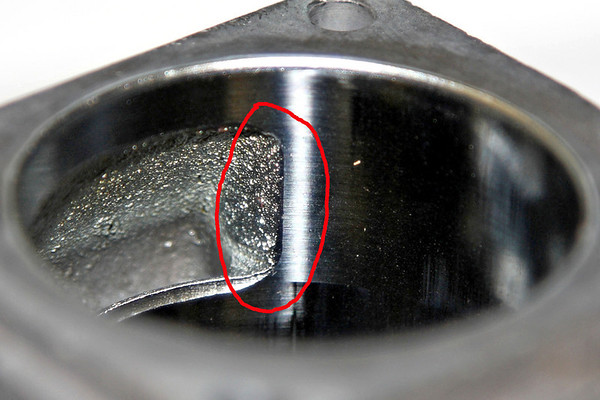

sure looks like it would be hard on the rings. Does your experience tell you otherwise? Is this how you would finish a transfer? Is this how other companies do it? Is this how Stihl has always done it? If not, then there has been a reduction in quality.

uummm.. that never touches the piston let alone the rings....

Nice casting ehh?

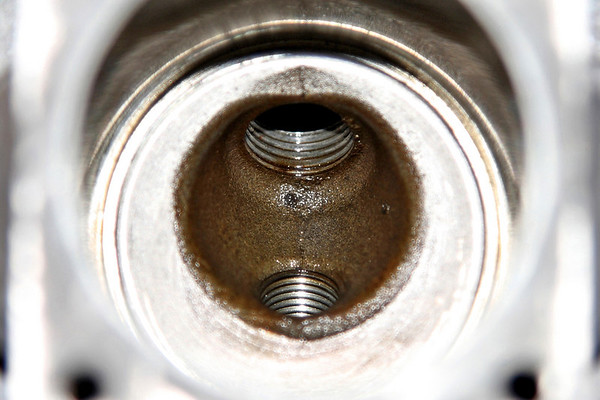

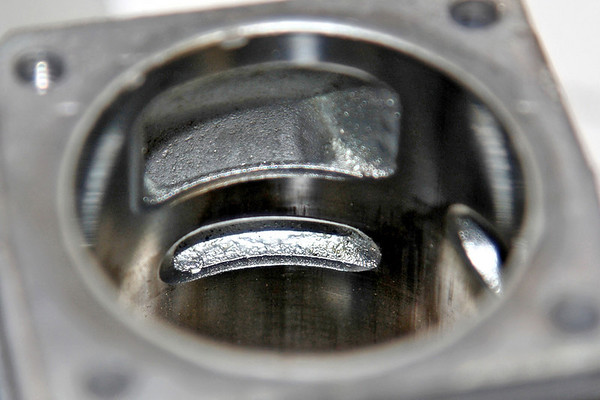

The combustion chamber isn't any too pretty either.

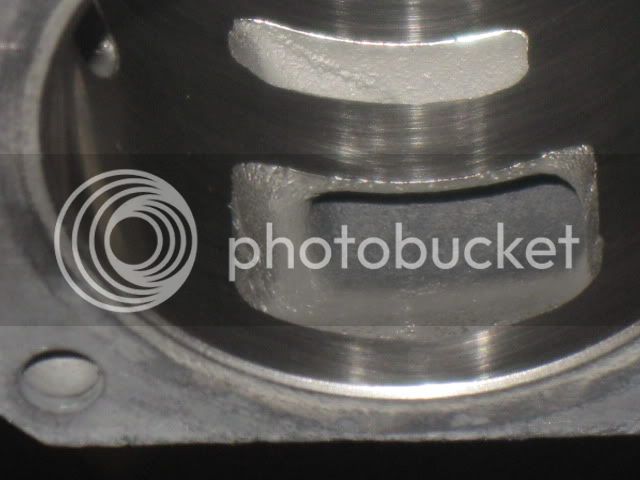

I noticed that ALL the ports are more beveled on the left side than the right. The transfers are particularly pathetic. You have a HUGE bevel on one side, and NONE on the other.

Right Front

Right Rear

Left Front

Left Rear

Here this is supposed to be one of Stihls professional saws. They have majorly dropped the ball on cylinder quality!

So much for Stihl quality ehh? Check out this crap I found in a brand new MS260! The piston is marked Mahle and looks good. The cylinder is only marked Stihl. What are they doing? Outsourcing this crap to China?! Sure looks like it. So much for bashing the BB kits and hold up Stihl as an example. At least Husky is stihl using Mahle cylinders on their pro saws that I've seen.

Finish of the transfers.

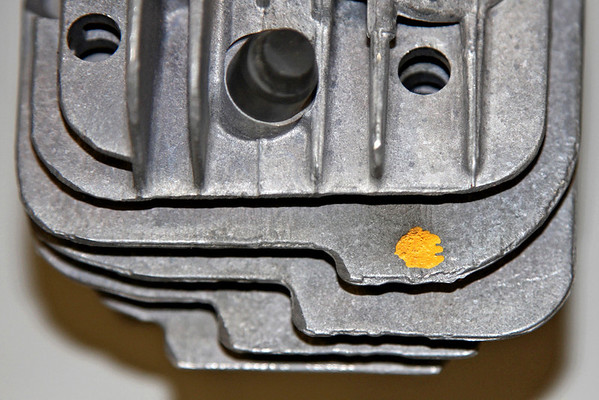

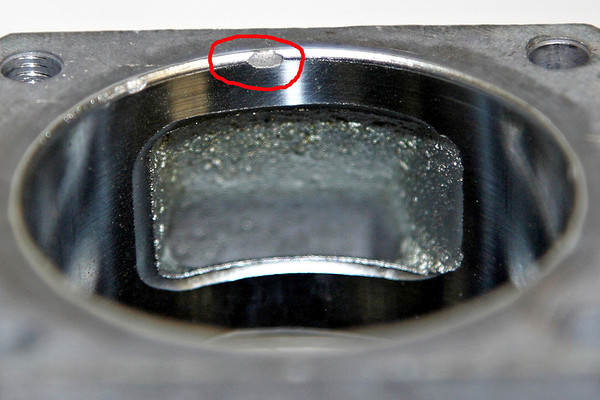

And check out this chip!!

Nice big bulge in the intake.

And a big lip from the other side!

Nice casting line.

Check out the edge of the exhaust port. And more nice casting flaws.