Sierradmax

ArboristSite Operative

Here's how I make my spikes. This is an example for a dual set on a 346xp.

First, I measure mounting locations of the inner spike holes on the crankcase then measure the outer. In the case for the 346, I used the bar studs to secure the outer spike. I use a degree wheel to find the offset in degrees and mm between the inner spike holes & the bar studs. After I input this in CAD, I design a spike profile based off bar height (I have a centerline with the bar studs). I like to get a tooth below the bar & one above.

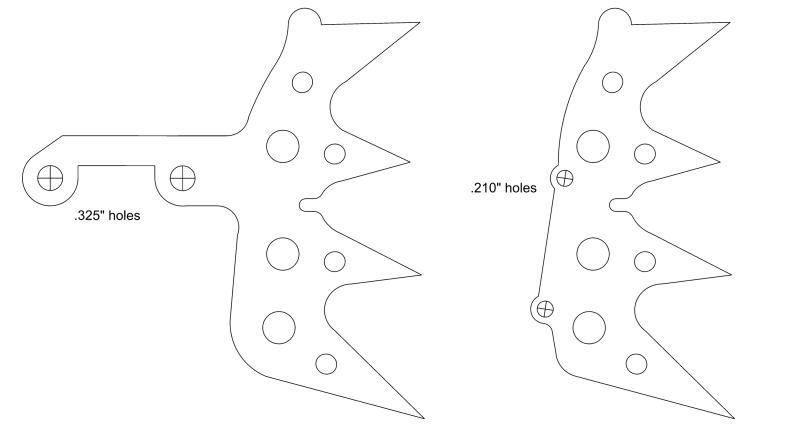

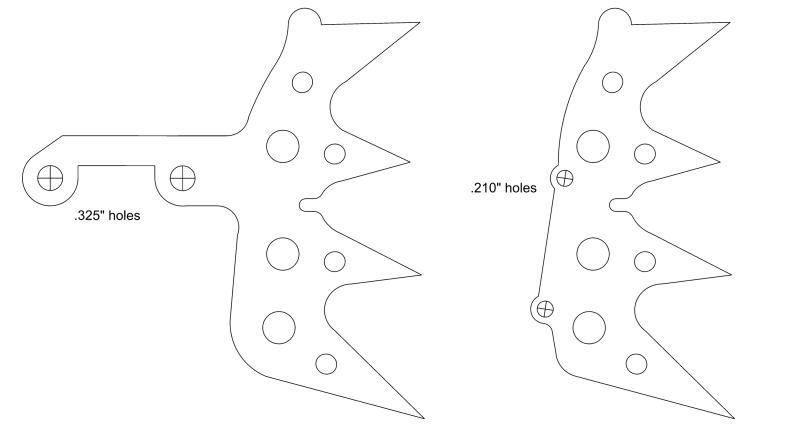

CAD file:

Printed 1:1 on card stock & mocked for fitment. I was a couple degrees off on the outer spike:

Final Product:

I agree with some of the peoples posts here. Bigger isn't always better. I have made a smaller set for the 346xp that, to me, are more effective and offer more useable bar length.

First, I measure mounting locations of the inner spike holes on the crankcase then measure the outer. In the case for the 346, I used the bar studs to secure the outer spike. I use a degree wheel to find the offset in degrees and mm between the inner spike holes & the bar studs. After I input this in CAD, I design a spike profile based off bar height (I have a centerline with the bar studs). I like to get a tooth below the bar & one above.

CAD file:

Printed 1:1 on card stock & mocked for fitment. I was a couple degrees off on the outer spike:

Final Product:

I agree with some of the peoples posts here. Bigger isn't always better. I have made a smaller set for the 346xp that, to me, are more effective and offer more useable bar length.