Fines passing through a filter then cutting dead Redgum are two different stories. If any filter system (like the new Dolmar HD) can pass the dead Redgum test then it is up there with the best. In fact I'm not even sure if I've heard of any non oiled stock filters passing the dead Redgum test, maybe the 372XP Huskies but not even sure about them? Where are ya Al (Aussie1)???\

My 390XP is held up in Customs so haven't had the chance to test the filter system on that saw out yet...

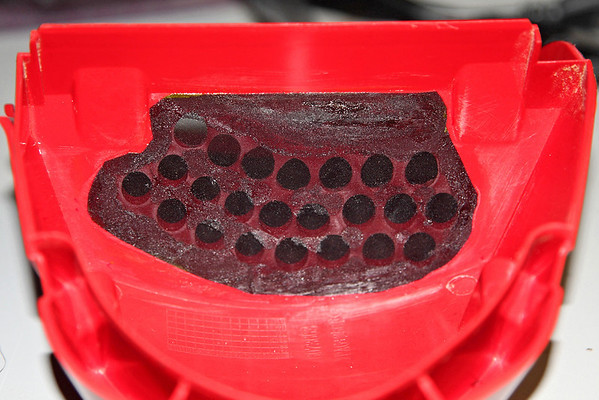

The fines that are passing through Brad's 681 filter aren't even what I would class as fine particles, they're huge. Redgum dust ends up more like a brown paste.

I've used the 7900 in green wood all day and the stock filter looked a treat, get it in dry, dead stuff though and it fails badly.

I've been planing on doing something like that to my 7900's for a long time now, I'm a lazy sob.

I've been planing on doing something like that to my 7900's for a long time now, I'm a lazy sob.