You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FarmerTec Huztl MS660 Updated Build Kit - Build Thread

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I just received my kit last week and I assembled it this weekend. I was shorted 3 M5 lock nuts and my “Choke Shaft” doesn’t come anywhere close to operating the choke. The choke shaft just detents into two positions. Run and off. No other positions. Anyone else get a choke shaft like this? All I need to order is a OEM one and I’m good to go?

thanks

thanks

MG porting

ArboristSite Guru

Not sure about the others but I've never seen happen like that but yes a factory one should work just fine.I just received my kit last week and I assembled it this weekend. I was shorted 3 M5 lock nuts and my “Choke Shaft” doesn’t come anywhere close to operating the choke. The choke shaft just derents into two positions. Run and off. No other positions. Anyone else get a choke shaft like this? All I need to order is a OEM one and I’m good to go?

thanks

Yes, that Mark shows up on most of theirs. I think they make most of their cylinders. But from time to time I think they have bought outside.Bedford T have a interesting thing to show you. I got another 54mm cilinder today the one on my ms660 ses farmertec right on it and the one I just got today doesn't but has a marking up on the combustion chamber have you ever ran across one of these before??? View attachment 628543

MG porting

ArboristSite Guru

OK cool the funny thing is this cilinder is really nice the ports are smooth and clean transfers are pretty nice as well I did notice that the port timing is different to so I'm hopping with this one I can get a little better low end grunt at a lower rpm the one on the saw makes power but at a highe rpm. And thanks for your info really appreciat it.Yes, that Mark shows up on most of theirs. I think they make most of their cylinders. But from time to time I think they have bought outside.

William Prophett

ArboristSite Operative

Update on the 660 56. Here is the fix for the chain adjuster... I ordered an OEM adjuster, and started having some problems with that one skipping. So I decided to rip it apart to put in the new HO oil pump and try to figure out where the problem was with the adjuster. On the left side of the threaded adjuster rod there is a worm gear and small stud sticking out that rests in a housing in the case. I've seen Walt talk about shimming these things and was going to machine a brass bushing to house the stud and fit snug in the housing. As luck and education would have it, my local (every time I go there I say why do I ever go anywhere else) mom and pop hardware store had the perfect size brass tubing for $1.56... You need to cut a piece off that is slightly longer than the stud and then just sand or file it down to be flush with the end of the stud and stick it back in... Slop is gone and the adjuster works seamlessly. I'll try to attach some photos. Finally put a final tune after break in time and ran the saw on the mill this past weekend. I set the high side at 13,000 and to say that I'm happy is a gross understatement. This thing blows my modified mill saws away. Idles perfect, tons of compression, revs like a 372... Milled up some 22" diameter pine logs to test the original oil pump and this thing doesn't even kniw there is wood getting in the way. I'll try to upload some videos that I took... Stay at it! I'll give a review on the new HO oiler as soon as I can put it back in some wood. I was running a 36" bar and to be honest, I really didn't have a big problem with the way the kit pump was oiling...

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

Glad you got it fixed. Walt got the fix here from another fella. Credit goes to him for figuring it out for all of us.Update on the 660 56. Here is the fix for the chain adjuster... I ordered an OEM adjuster, and started having some problems with that one skipping. So I decided to rip it apart to put in the new HO oil pump and try to figure out where the problem was with the adjuster. On the left side of the threaded adjuster rod there is a worm gear and small stud sticking out that rests in a housing in the case. I've seen Walt talk about shimming these things and was going to machine a brass bushing to house the stud and fit snug in the housing. As luck and education would have it, my local (every time I go there I say why do I ever go anywhere else) mom and pop hardware store had the perfect size brass tubing for $1.56... You need to cut a piece off that is slightly longer than the stud and then just sand or file it down to be flush with the end of the stud and stick it back in... Slop is gone and the adjuster works seamlessly. I'll try to attach some photos. Finally put a final tune after break in time and ran the saw on the mill this past weekend. I set the high side at 13,000 and to say that I'm happy is a gross understatement. This thing blows my modified mill saws away. Idles perfect, tons of compression, revs like a 372... Milled up some 22" diameter pine logs to test the original oil pump and this thing doesn't even kniw there is wood getting in the way. I'll try to upload some videos that I took... Stay at it! I'll give a review on the new HO oiler as soon as I can put it back in some wood. I was running a 36" bar and to be honest, I really didn't have a big problem with the way the kit pump was oiling...

William Prophett

ArboristSite Operative

William Prophett

ArboristSite Operative

William Prophett

ArboristSite Operative

Sorry I didn't take any photos of the one that I installed on the saw. I didn't think about it until it was all back together.

William Prophett

ArboristSite Operative

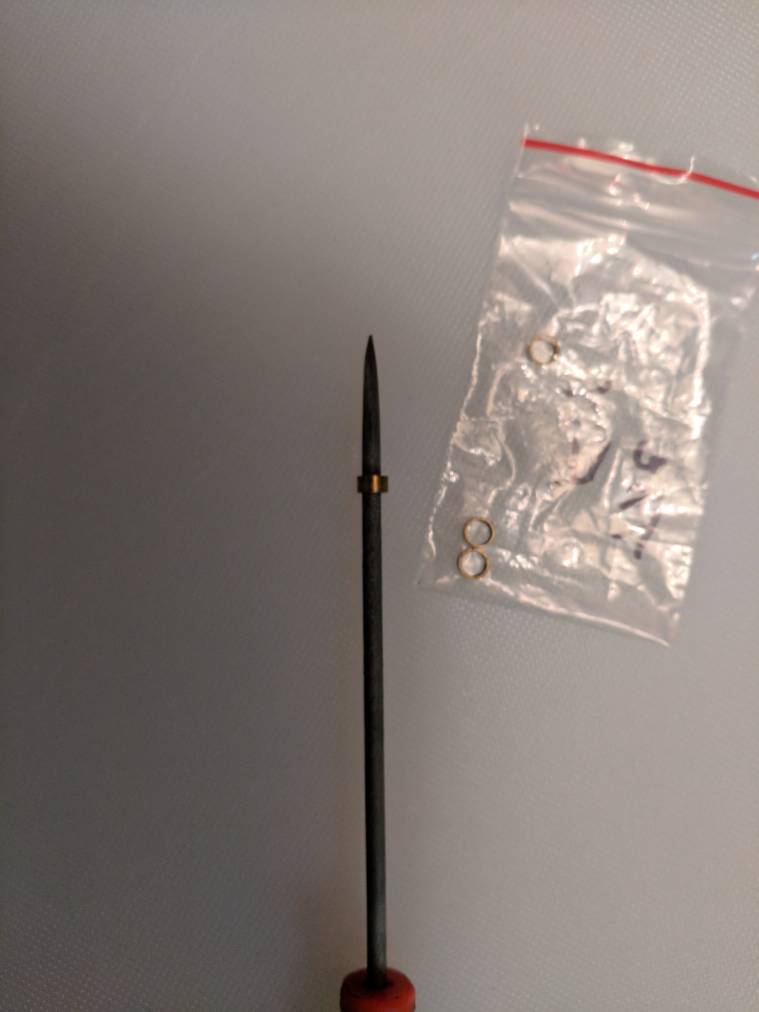

Interesting. Which leads me back to my theory that they shipped a bunch of "old leftover stuff" for that Black Friday sale. I just got my kit in December and had to shim an OEM adjuster...Here is a photo of some that were left overs. Giving you a perspective for those that wound up with a old style case and might need one. It's the case not the gear that's the issue.

gchamber

ArboristSite Member

cre73

Always Lurking, never posting

View attachment 629587 View attachment 629588 View attachment 629589 View attachment 629590 View attachment 629587 View attachment 629588 Has anyone had issues with the t27 heads breaking off of the cylinder head bolts? I just found 3 of my 4 broken....

Any chance you checked the top of your piston for damage? What was your squish? Just a thought.

MG porting

ArboristSite Guru

Well although I can say yes but not on the ms660 it can happen even on the oem saws. How are you tightening them? But easy fix if the heads just broke off flush at the top of the cylinder will take time and patience .View attachment 629587 View attachment 629588 View attachment 629589 View attachment 629590 View attachment 629587 View attachment 629588 Has anyone had issues with the t27 heads breaking off of the cylinder head bolts? I just found 3 of my 4 broken....

There is more to it than yes it's possible. He needs to take a hard look at what he did and did not do. The math is on the high sideWell although I can say yes but not on the ms660 it can happen even on the oem saws. How are you tightening them? But easy fix if the heads just broke off flush at the top of the cylinder will take time and patience .

gchamber

ArboristSite Member

Yes I was cutting with it. Then saw shut off. Would pop on choke and then run for a few seconds and cut off. Then I felt something hit my boot and found that bolt head on the ground. Was trying to remember what bolts were black, then dread set in when I realized the head bolts were the only thing I could think of that were black. Took the saw apart and found 2 others were missing as well.

Just checked the top of the piston, and don't see any marks that indicate any collisions with the spark plug or the decomp plug (no valve)

Just checked the top of the piston, and don't see any marks that indicate any collisions with the spark plug or the decomp plug (no valve)

gchamber

ArboristSite Member

I am tightening them with a t27 screw driver by hand. Tightened in a cross pattern.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 32

- Views

- 3K