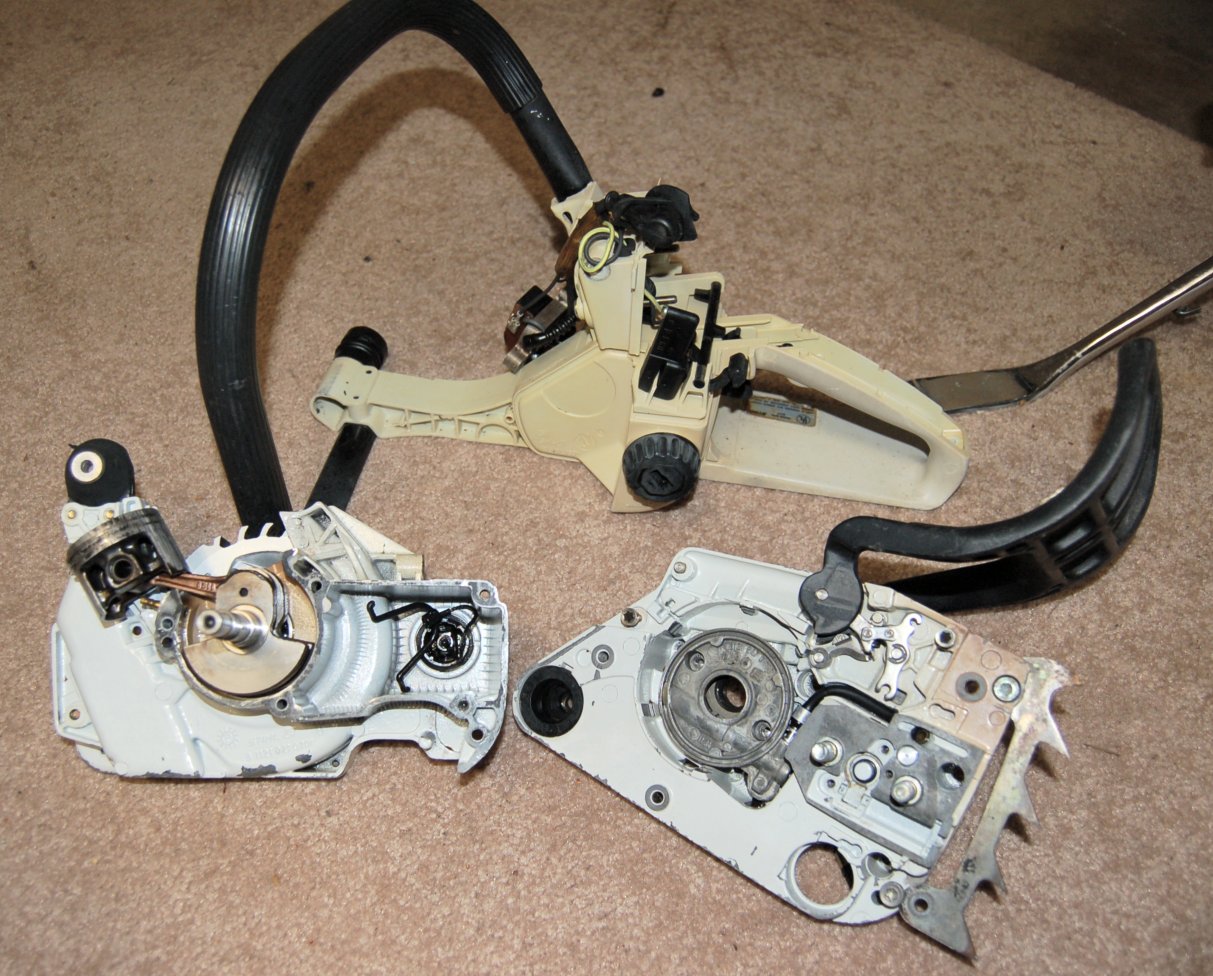

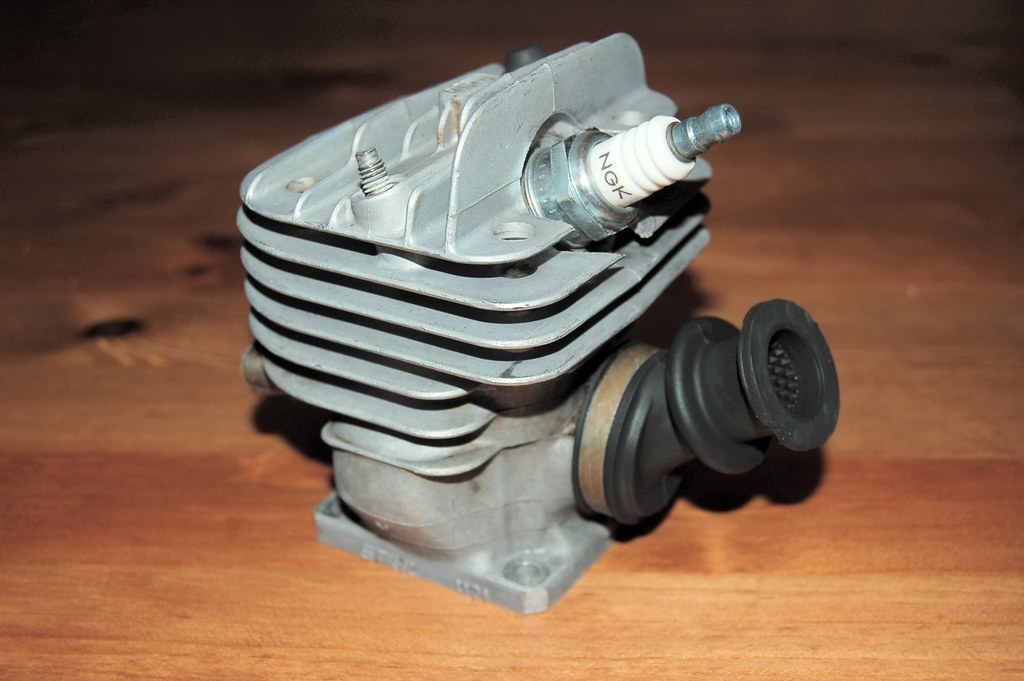

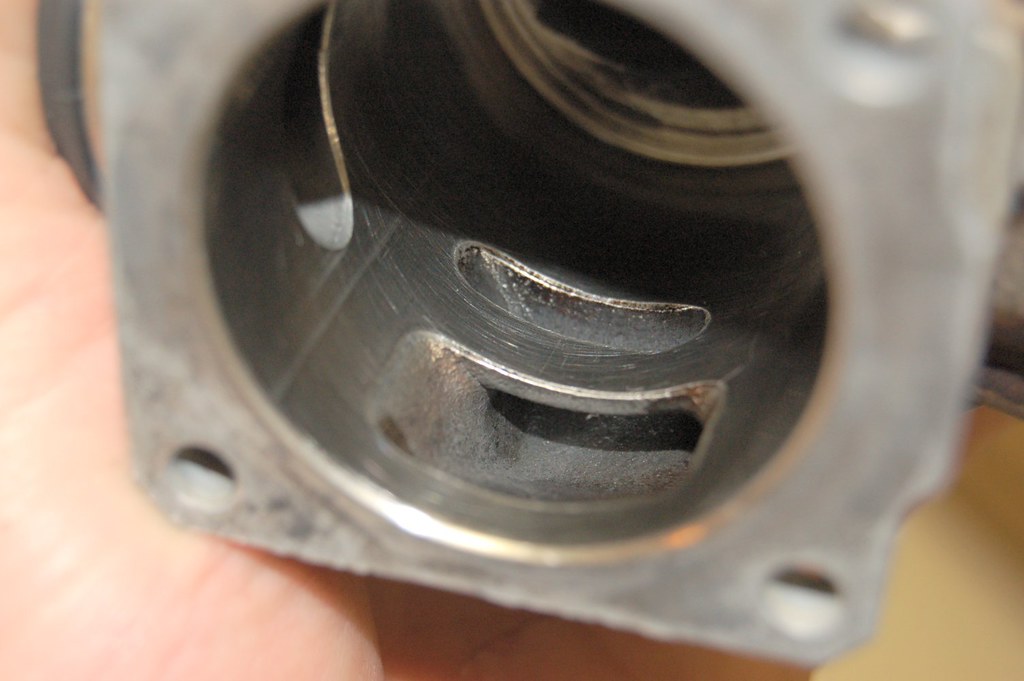

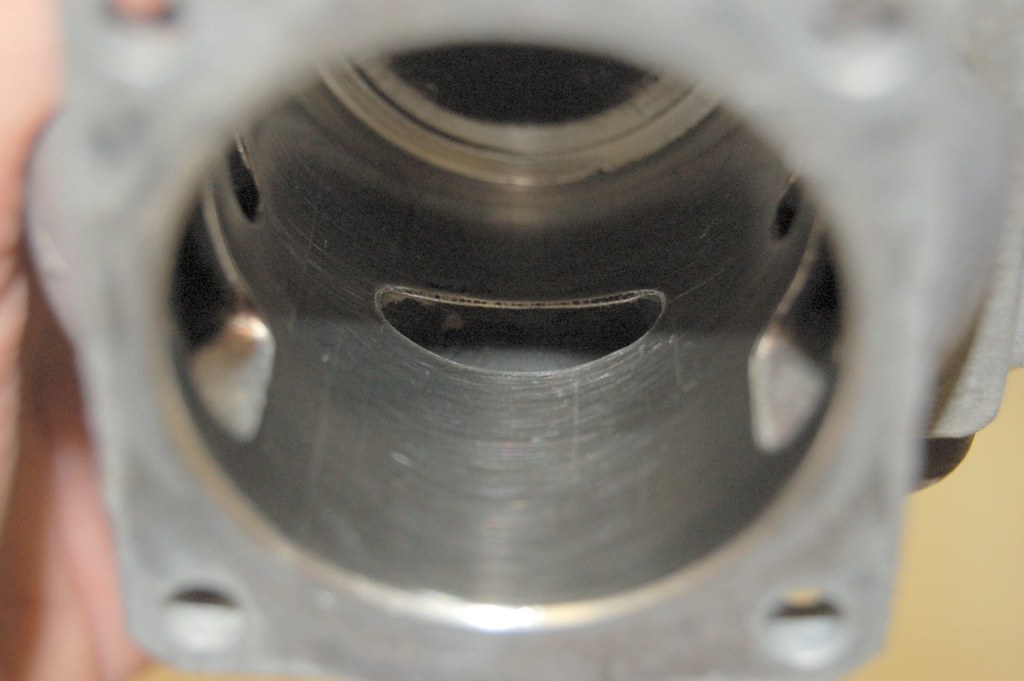

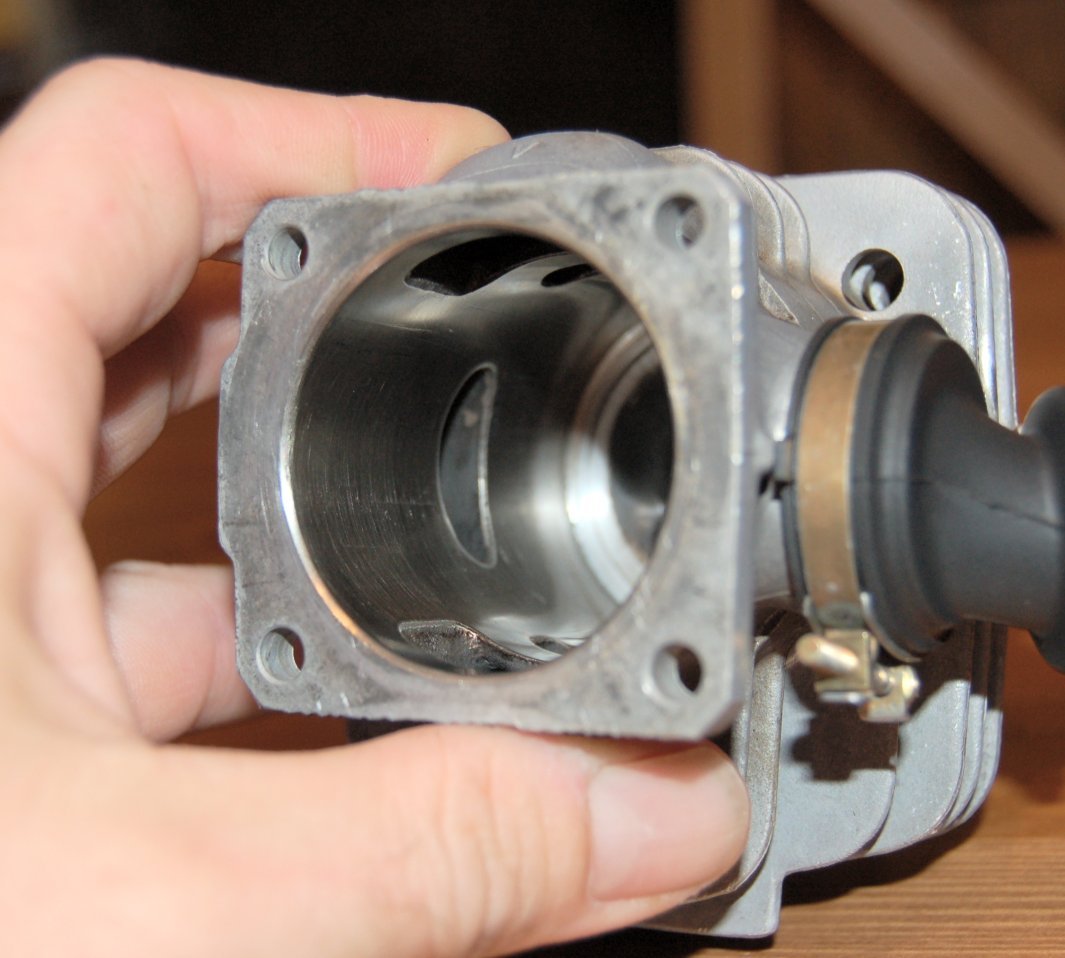

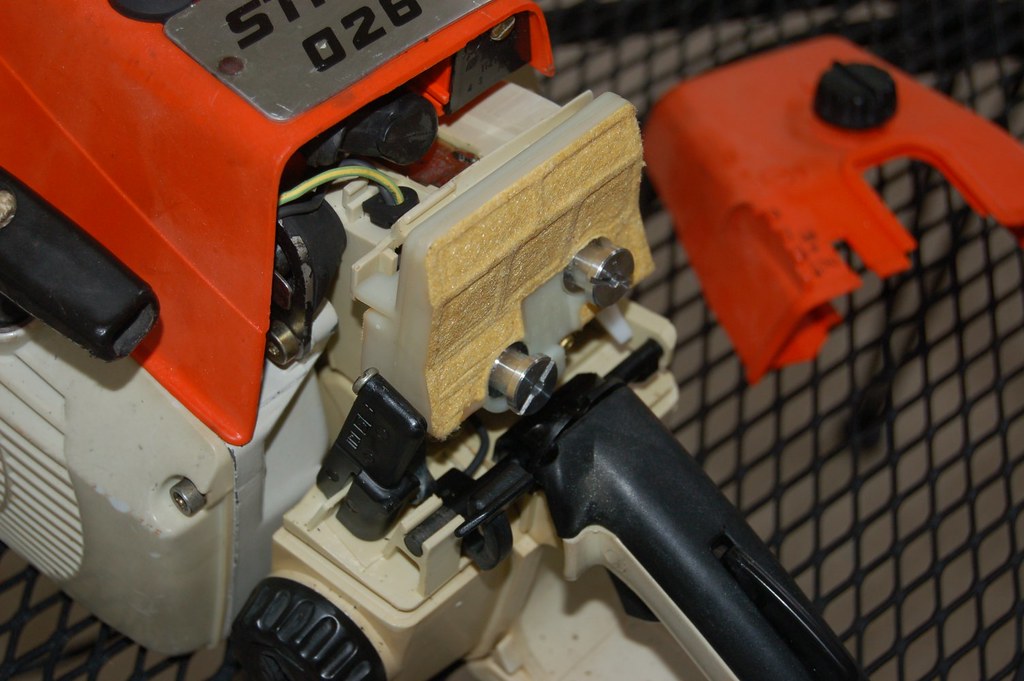

That slug is shot, I think you will need more than a piston. That saw looks pretty old, riveted name tags were on the first ones I believe. There may be a year on the green tag attached to the chain brake, but it could have been replaced also. Tree spike is on upside down. Looks good for the $$$, complete anyway.

The info on the green tag is dated 1985, there is also another number starting with 000096 etc which looks like it might be a weird date system like year, day, month, etc. Looks like it might have been made in 1996? Regardless of date all the rubber parts are in great shape including the carb boot and the fuel and impulse line.

BTW, I think the spike is set up for inverted cutting.... LOL. I noticed that right off too.

I'm stihl hoping for someone to come along and assign a date to this saw..... Anyone, anyone, Buhler?