mcb

ArboristSite Operative

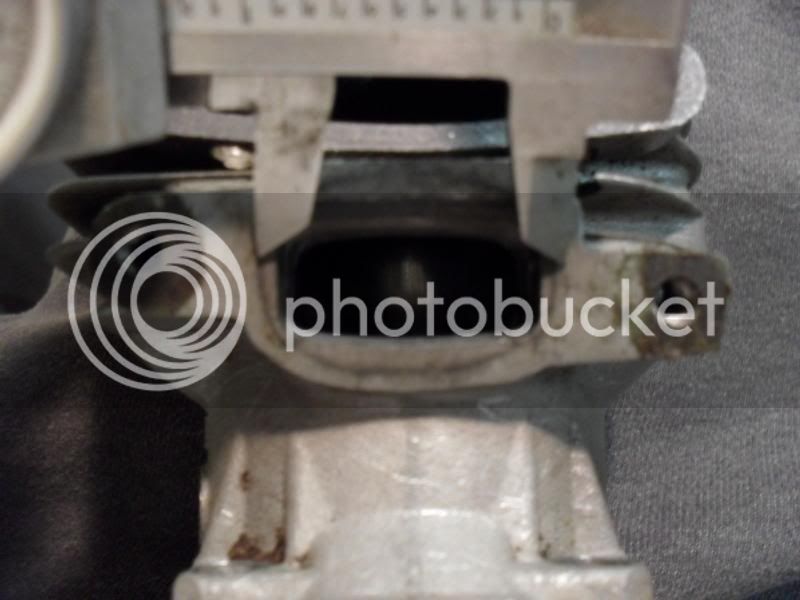

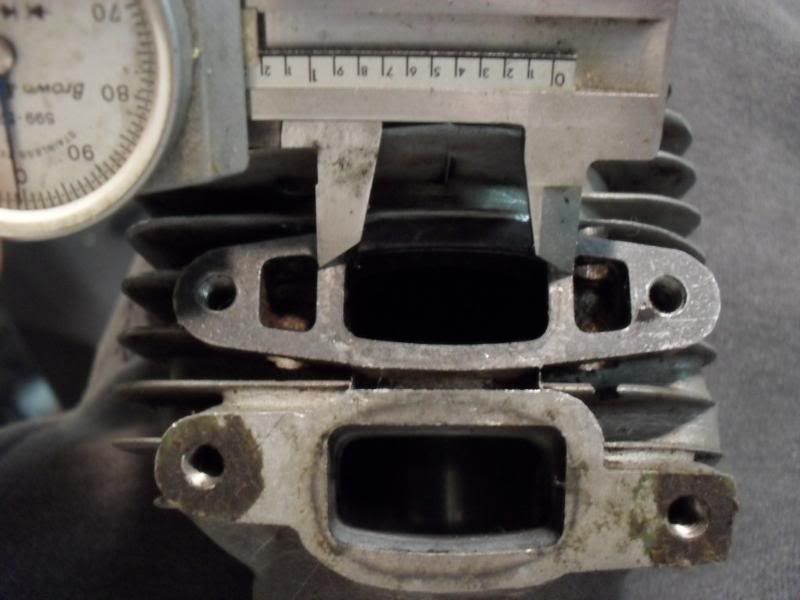

pulled the gasket back out which is how i intend to run the saw, in addition to milling the base about .020" and bringing down the compression height margin on the piston. this will minimize quench pad distance at tdc, allow adequate clearance for the peripheral squish band and retard transfer port opening as much as possible to extend blowdown and get some breathing done.

so i rezero'd my wheel by ensuring that the crank was at top dead center and the piston was at its highest position in the bore.. (when the "minute hand" sweeps to and from a single number, reversing direction, thats TDC. i set my gauge to "0" for this to make it easy)

bent the pointer right ontop of zero and rechecked my measurements.

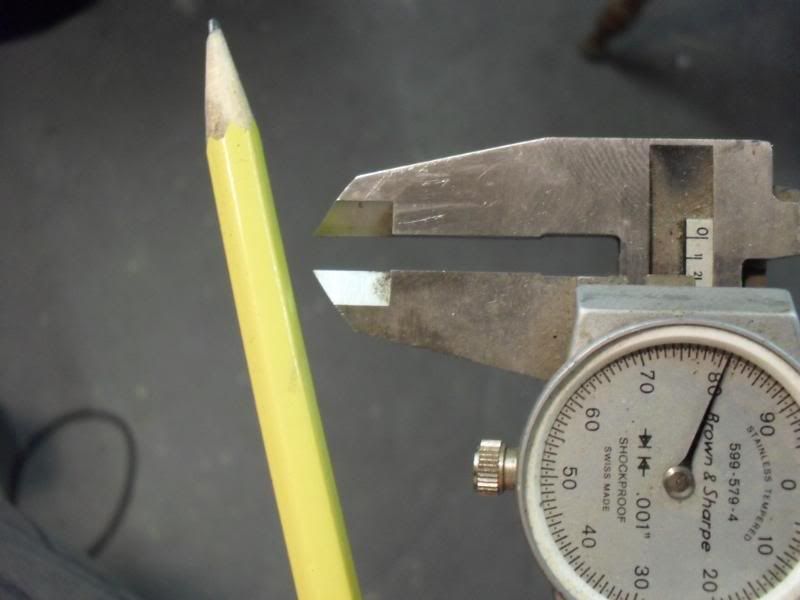

ive been using a .004 feeler to mark when the port is open or closed for consistency.. looks like this:

turns out i had my transfer port opening off about 3* .. they actually open at 120ATDC, giving me 11 degree of blowdown timing, which you can count here as the difference between exhaust open and transfer open.

im still convinced the 041 is a slow revver because the blowdown period is too short because of the late (retarded) exhaust valve opening time at 109*ATDC when it should, IMO, be closer to 90*ATDC. i did a poor job of explaining why these spit fuel back a few posts up. it is indeed because of inadequate time frame to exhaust itself but i said that it was a simple case of intake charge contamination. its more than that. because the blowdown period is inadequate, the pressure above the piston is still very high when the transfers open. the exhaust gas is blowing into the crankcase through the transfer port, and then right out the intake/carb. my prediction is more blowdown will do this saw a world of good.

ive read 30* of blowdown is customary for high performance application, but im thinking too much rpm will kill bearings and rattle the saw to death, so i feel like 25* is more reasonable and still more than double what i have now, plus id like to keep some torque and you cant have torque without compression. you dont build compression if you have the valves open all the time.

so i rezero'd my wheel by ensuring that the crank was at top dead center and the piston was at its highest position in the bore.. (when the "minute hand" sweeps to and from a single number, reversing direction, thats TDC. i set my gauge to "0" for this to make it easy)

bent the pointer right ontop of zero and rechecked my measurements.

ive been using a .004 feeler to mark when the port is open or closed for consistency.. looks like this:

turns out i had my transfer port opening off about 3* .. they actually open at 120ATDC, giving me 11 degree of blowdown timing, which you can count here as the difference between exhaust open and transfer open.

im still convinced the 041 is a slow revver because the blowdown period is too short because of the late (retarded) exhaust valve opening time at 109*ATDC when it should, IMO, be closer to 90*ATDC. i did a poor job of explaining why these spit fuel back a few posts up. it is indeed because of inadequate time frame to exhaust itself but i said that it was a simple case of intake charge contamination. its more than that. because the blowdown period is inadequate, the pressure above the piston is still very high when the transfers open. the exhaust gas is blowing into the crankcase through the transfer port, and then right out the intake/carb. my prediction is more blowdown will do this saw a world of good.

ive read 30* of blowdown is customary for high performance application, but im thinking too much rpm will kill bearings and rattle the saw to death, so i feel like 25* is more reasonable and still more than double what i have now, plus id like to keep some torque and you cant have torque without compression. you dont build compression if you have the valves open all the time.