Some good news, and a little more headache.

I can happily report that after putting everything back together, the 550 seems to run great. The carb settings aren't quite there yet, it's a bit reluctant to want to get going from a cold start, wants to die after a few pops unless you give it some throttle, but once it warms a little it idles just fine.

The crank seals appear to still be good. After letting things warm up for several minutes until it was running hot, I only had to turn the hi jet out about another 1/8 to get it four stroking at WOT again. Turning the saw from side to side has no noticeable effect. One of these days, hopefully sooner than later, I'll get a proper pressure testing setup so I can know for sure when things are bad.

Currently I think I have the needles at about 1 1/2 hi, 1 1/4 lo. Does that sound about right for this saw?

Anyway, as for my headache... One thing I noticed was that something felt off about the oil delivery. It was definitely there, but it just seemed weak. Even the manual oiler didn't feel like it had very much pressure when I was pushing it in.

It wasn't until nearing the end of my initial warm up test that I noticed I had bar oil leaking out all over the back of the saw, and oozing down towards the on/off switch and spark plug.

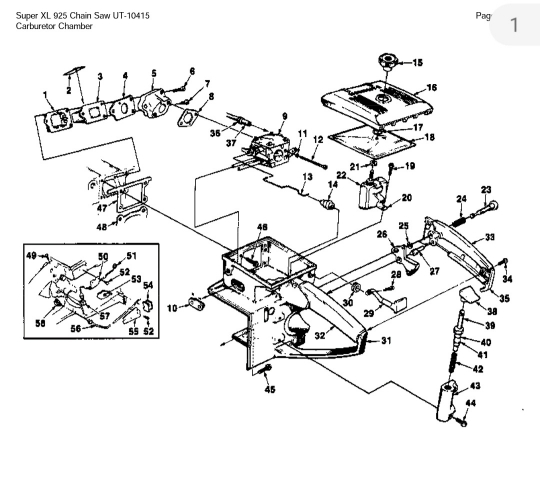

Turns out what had happened is that in my effort to stretch and push one of the new oil lines onto the annoyingly large barb on the oil pickup, it had made a small tear at that point, allowing bar oil to slowly ooze out.

It's so tiresome. This is like when I had to figure out how to fit my new aftermarket fuel line onto the large barb of my 10-10A's SDC without having it tear apart in the process.