No need to pull case halves together with bolts,

http://www.arboristsite.com/community/threads/installing-crank-bearings-using-heat.131284/

http://www.arboristsite.com/community/threads/installing-crank-bearings-using-heat.131284/

Thanks for that. How big is the brass hammer you use? I was using a rubber mallet with limited success.No need to pull case halves together with bolts,

http://www.arboristsite.com/community/threads/installing-crank-bearings-using-heat.131284/

Thank you sir!Mine is one I turned on the lathe, probably 8 - 10 oz. It takes a sharp rap rather than a heavy swing and hit.

Heres a nice little hammer set.No dice at the local hardware hank either. Probably 50 different hammers, no brass ones. Oh well eBay it is.

Brian

Looks like a good buy! Go for it!Grizzly H6320 12 oz. Dead Blow Hammer, Brass https://www.amazon.com/dp/B0007D2D50/ref=cm_sw_r_other_awd_UyA.wb0WECYV0

I might get this one, here by Saturday for $15

Brian

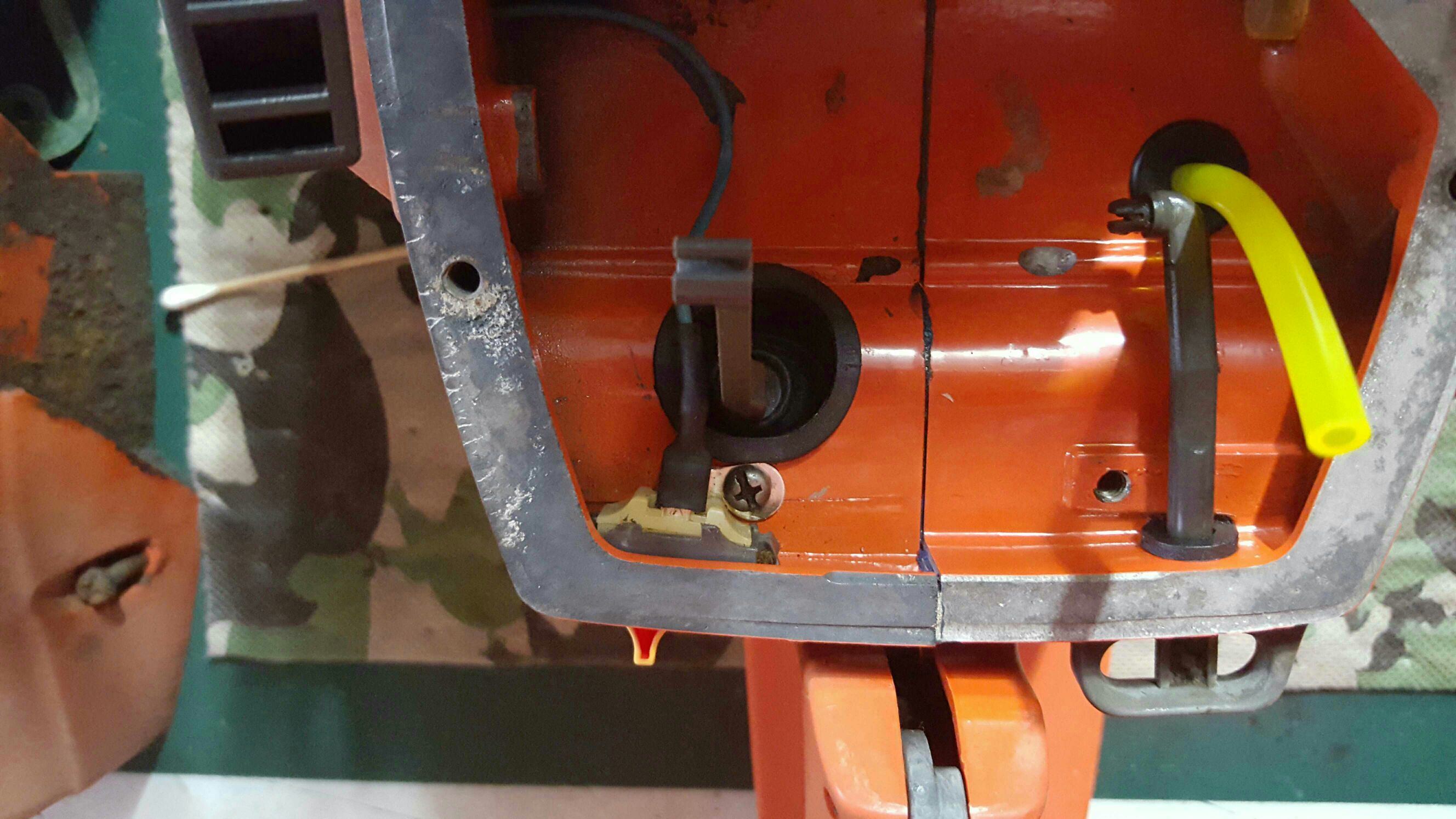

Coil question. Do you think that these parts are all interchangeable? Meaning can I use any small part with the spark plug wire with any of the parts that interact with the flywheel magnet? I have no experience with the two piece ignition system. My system design experience gut feeling is they almost have to be interchangeable and just switched the look and feel as they made cost reductions and moved suppliers.I rewired all the coils, ready to go now, not sure they all work but at least the wires have insulation and can't short to anything. I soldered on new wires, shrink tubed the bare area. New spade ends I will wait to do until I feed the wire through the grommet on case.

Brian

Nice man! I know they are! I had signed up for prime last month and ordered a few things and all my stuff was here in 2 days guarenteed!Amazon is creepy fast.

Brian

I should have listened to you. This method is what finally worked on the last of the 3.Just put the bearings on the crank first, tight to the counterwieghts. Then put the crank with bearings on it in the flywheel side half first till the bearing bottoms in the case. Then put the clutch side half on. The bearings will be in the correct location when you are done. I usually use a toaster oven and freezer to heat or cool parts as nessecary so everything just slips together.

I should have listened to you. This method is what finally worked on the last of the 3.

Brian