I have also used a heat gun, aim it at one side, then when the part farthest away from the heat is too hot to touch it is ready. If it starts to smoke (assuming it was clean of oil and sawdust to start with, since they will smoke earlier than the paint), then the heat has been on that spot to long and move the gun to the opposite end of the case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husqvarna 162, 2x 266, 268 Frankensaw Project

- Thread starter briantutt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

briantutt

Addicted to ArboristSite

Maybe the smoke is the clue!I don't know what temp my little toaster oven gets up to, I just know that I turn the dial to 4 minutes, the timer dings, then it is warm enough. There is no temp control on it. 4 minutes on my toaster oven is just before the case half start to smoke, figured this out through trial and error.

Brian

briantutt

Addicted to ArboristSite

So reading through the service manuals I have one of them says to put the piston ring down in the cylinder to check the gap. If it measures over 1 mm it is worn. The 162 is gap of around .88mm but the 266 is over 1 mm for sure. Guess I need a ring for that one.

Brian

Quoting myself, good trick huh?

Need advice. For giggles I put the new ring in the recovered 268 cylinder. There is only about .009 inches if gap between ring ends. This makes me think I should replace the rings in both the 162 jug and the 266 since they measure literally 5x what that new ring does for gap. I have no experience here. The service manuals say 1mm max but that is .039 inches, almost 5x the new ring measurement with the new ring at .009 inches.

briantutt

Addicted to ArboristSite

So I finally am to the point to mate some of the case halves. I do not have the tool for "pulling" the crank into the bearing/case. Bolts are to short. Is there a way to do it without the tool? Freeze the crank maybe?

Brian

Brian

briantutt

Addicted to ArboristSite

So reading through the service manuals I have one of them says to put the piston ring down in the cylinder to check the gap. If it measures over 1 mm it is worn. The 162 is gap of around .088 but the 266 is over 1 mm for sure. Guess I need a ring for that one.

Brian

New 266 ring has .007 inch gap so wow, they must wear quite a lot. I HAD a new ring for the 162 but I was not paying attention and stuck it on the 266 piston which is 50mm not 48mm and then broke it trying to take it off (stupid mistake).

Ordering a new one now.

Big Block

WFO or I don't go

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$38.99 ($0.39 / Foot)

$40.99 ($0.41 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

briantutt

Addicted to ArboristSite

Big Block

WFO or I don't go

I think I missed something!

Brian

There is a lot of good info in this thread. He is involved in a project like this and needed some help with what parts fit what saw.

briantutt

Addicted to ArboristSite

briantutt

Addicted to ArboristSite

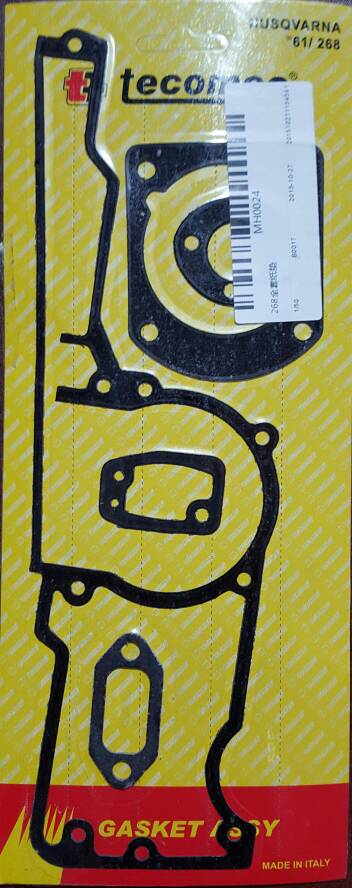

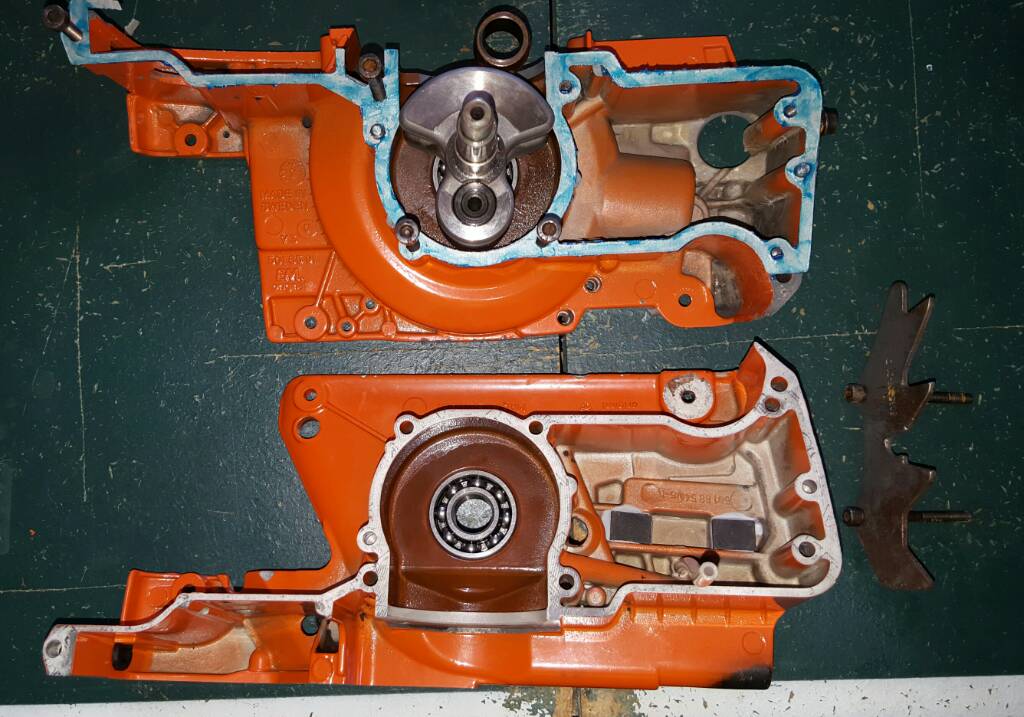

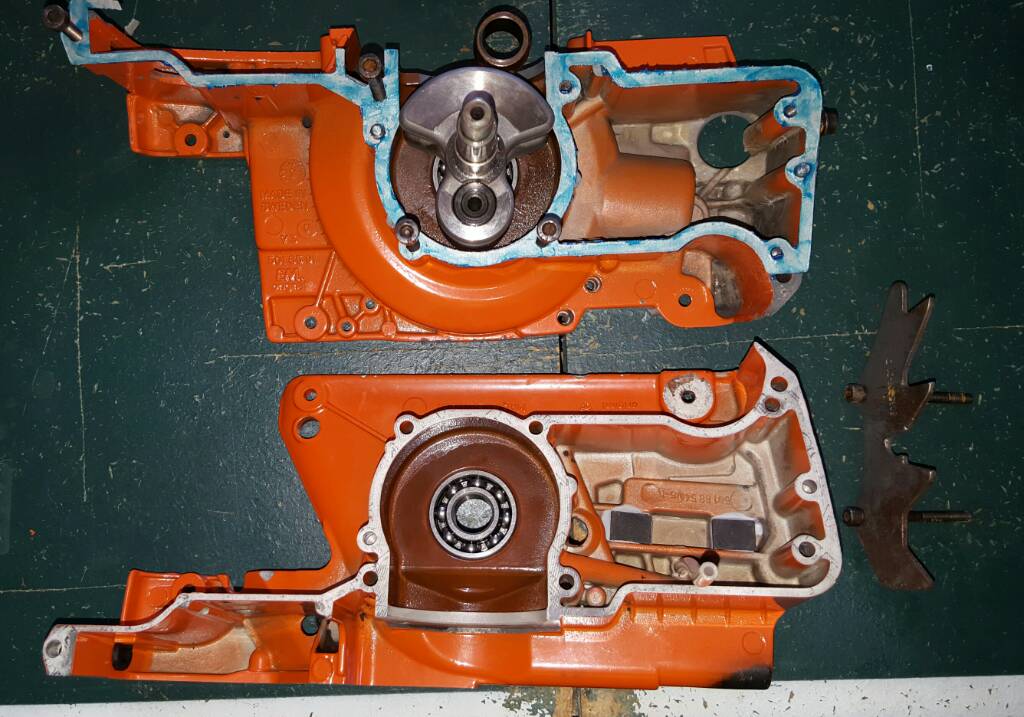

All bearings and cranks are set. I ordered some Hylomar blue to hold and seal the case gaskets just need it to arrive and one more gasket set.

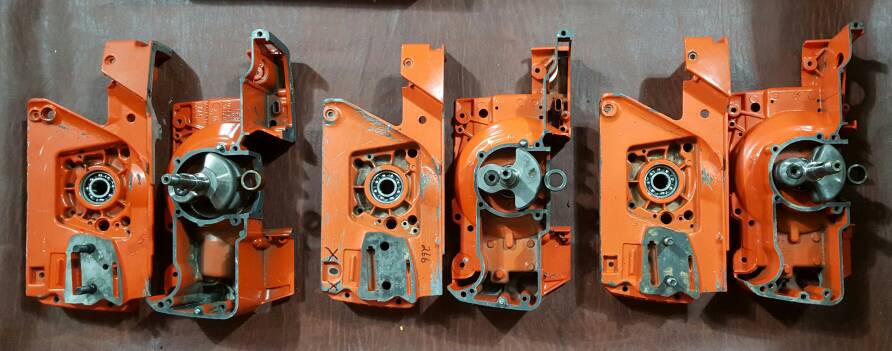

Notice the middle 266 clutch side case. The chain catcher mounting area is an odd ball one. With the rounded top. Finally dug through ipls online and found part number is 501 53 11-01 but cannot find one. [emoji35]

Brian

My 162 is dual thin rings, werent they all the same?

Cut the heads off some long 5mm screws for guide pins. Holds the gasket in position and avoid an Oops!

briantutt

Addicted to ArboristSite

Hylomar is on the 268, gasket is in place, that half going in the freezer. Plan to use heat gun to heat bearing on the other side in an hour and hopefully the 2 halves slip right together.

Brian

Brian

Similar threads

- Replies

- 15

- Views

- 48K