Spokerider

ArboristSite Operative

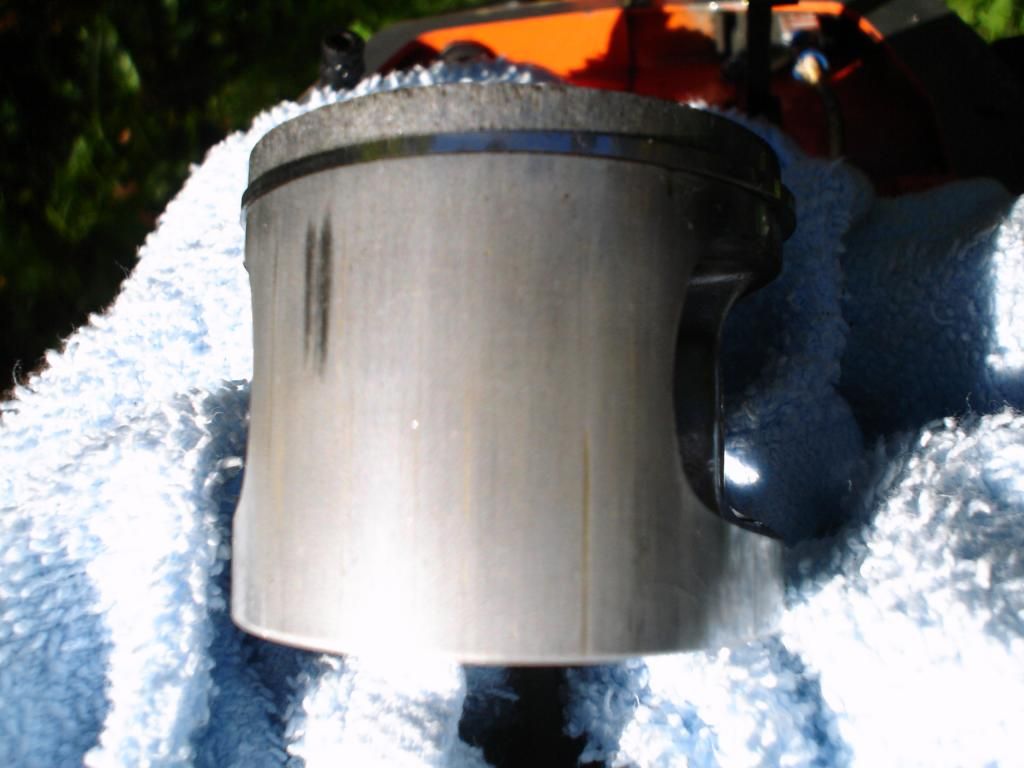

I just picked up a non running 266 SE for cheap............going to try to get it running again. PO said it just quit, wouldn't restart, so I'll begin with a new plug and check for spark. I'll go as far as rebuilding the carb, and changing the coil......might be willing to replace the piston and ring if needed.

Anyway........I did notice that one of the muffler bolts [ cylinder head stud holding muffler on? ] is stripped. Have read this is a common problem with these saws. How to fix?.......aside from a new cyl head. Helicoil thread repair work for this?

If it were to need a new piston and ring, who makes the best aftermarket parts, aside from OEM Husqvarna ? Meteor? NWP? Some thing from China? These all seem to be available on ebay.

Thanks.

Off to buy a spark plug.......

Anyway........I did notice that one of the muffler bolts [ cylinder head stud holding muffler on? ] is stripped. Have read this is a common problem with these saws. How to fix?.......aside from a new cyl head. Helicoil thread repair work for this?

If it were to need a new piston and ring, who makes the best aftermarket parts, aside from OEM Husqvarna ? Meteor? NWP? Some thing from China? These all seem to be available on ebay.

Thanks.

Off to buy a spark plug.......