i have had just two of ten that were noticeably out of wack...left the others in their plastic so don't know how they are.The 8 or so that I've had in my hands have all been round, must be hit or miss with you having the bad luck so far.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Huztl MS660

- Thread starter Kyler Monares

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Of the seven I have installed, 4 or so were not out of round by visual inspection. The others weren't perfectly round but just barely visually detectable. I probably would not have noticed if Weimedog had not mentioned it previously.

Sounds like I might need to look more closely.

Have to put in on the crank with bearing then check the run out. Its the alignment relative to the internal diameter of the bearing surfaces..Sounds like I might need to look more closely.

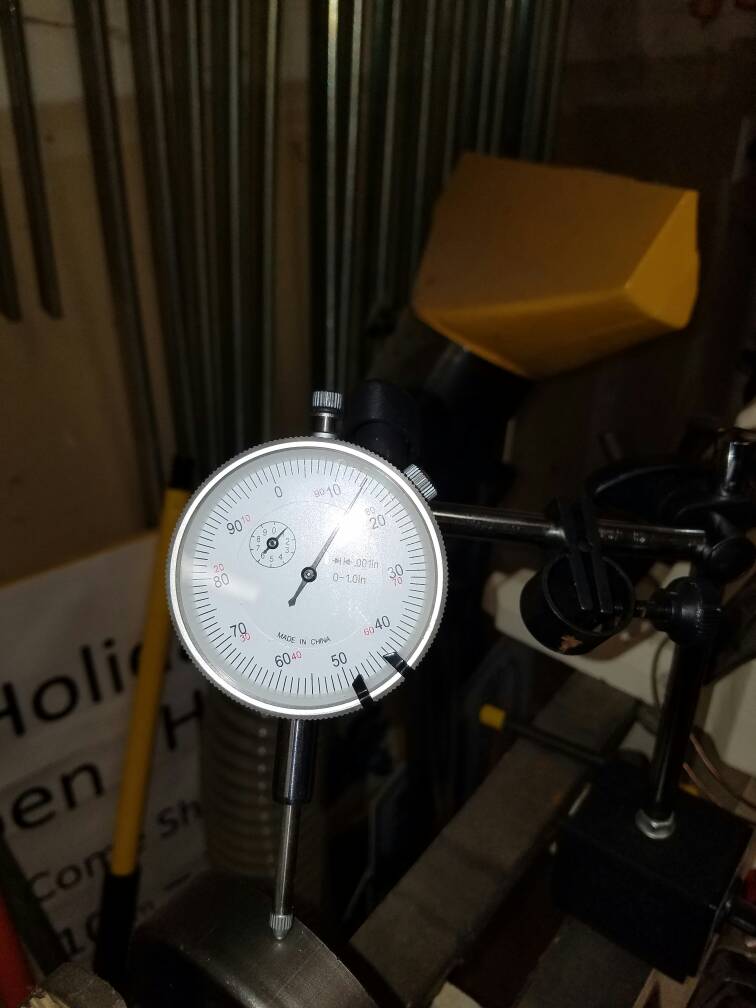

There's more variance in the fit of the rim sprocket than there is along the rim of the clutch drum. I measured 2 at random and only got about .005 difference between and that could be attributed to me not taking enough time to ensure that the mounting on the chuck was absolutely perfect.

I'm not saying that folks haven't gotten out of round drums, just that my experience is different so far.

I'm not saying that folks haven't gotten out of round drums, just that my experience is different so far.

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$29.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

I found a 381 clone on AliExpress for $285 delivered. I have never ordered from Alibaba, AliExpress, DHgate, and the like. Now that Huztl is offering the MS 440 kit I'm not sure I'm ready to risk sharing my payment information and/or risk receiving a crappy saw. Here is the address.

https://www.aliexpress.com/item/MS3..._5&btsid=1aee2122-d8aa-41ca-bd8e-f874205cf8c3

Trust me, the Chinese already have all of your personal and financial information, go ahead and buy with confidence.

Outside runout of the clutch drum means nothing.

Total inside runout of a 1/64" or less is acceptable in my humble opinion.

Total inside runout of a 1/64" or less is acceptable in my humble opinion.

Outside runout of the clutch drum means nothing.

Total inside runout of a 1/64" or less is acceptable in my humble opinion.

Yeah, that's why I showed measuring the inside of the drum too and compared the two.

The drum and center (spur or rim spline) is furnace braised together an sent out the door. So you will always have some runout.

Mine are no where near that true...not even in the same league. Especially from ID where the bearing sits to od of drum. One had almost .100 wobble. Pitched that puppy.

Did you measure from the ID where the bearing sits?And was that ID bearing surface square to the rest of the drum on yours? Mine wasn't hence the wobble on one and on the other the bearing surface was actually off center. Not even sure how they accomplished that.Yeah, that's why I showed measuring the inside of the drum too and compared the two.

Looks like he chucked it to the sprocket hub. Would that check that both are true even to each other?

I chucked to the sprocket hub, and yes that would check both as the OD and ID of the sprocket hub are parallel to each other unless they screwed up the bore on that too. He's describing a failure to get the sprocket hub correctly mounted to the drum during braising, that's both a mfg defect and a failure of QA as it should be visibly wrong on cursory inspection. This part is in no way a high precision part else it would be mfg'd differently.

Ash UK Chopper

ArboristSite Lurker

Where to buy? It is for vacuum and pressure?Cooking on gas now.... View attachment 546527

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,088

Great Thread Guys

I have a couple quick thoughts on the aftermarket 660 kits and Huztl in general - I read up a little here, now and then but don't post as much as I once did.

Alibaba is bigger than ebay and google and amazon combined, I don't do business there often but have found new vendors there in the past.

Farmertec, Arbortec, Huztl are all the same company, out of the same building, they have several other seller names on Ebay for other countries (which seems to violate the Ebay terms of service but...whatever).

All of the "manufacturers" putting bundles together will freely substitute a different part if they can find it cheaper or run out of their current stock, so never count on anything you read to be 100% accurate.

As @weimedog has shown there are at least 4 different big bore MS660 cylinders from Farmertec et al in the last year alone and if they get a better price on them you can bet there will be 4 more next year.

All the great info in this thread should serve as a guide, not as gospel for that reason.

Your individual business means little to these "importers", there are companies that spend $100K annually with Farmertec and we get the same mumbly mouthed half answers and excuses, the only places with enough clout to get things done are the HLSupplys, Baileys, etc of the world who buy multiple shipping containers of parts each month.

I have a race saw built on the Clone660 by a great builder and there were a handful of parts that didnt hold up to even rudimentary race testing.

He had me send an OEM piston, cylinder, circlips, piston pin, bearings (all), flywheel, ignition coil, crankshaft (this was before the good cranks were available from NWP in Taiwan, the FT cranks suuuuck), rope rotor and pawls, we also swapped to Caber rings for a little more compression.

I need to get that puppy out and make some videos with some of my other ported 1122s.

If anyone needs an earlier good 660 crankcase I think i have more than a dozen left in stock.

Capitalist Dave

I have a couple quick thoughts on the aftermarket 660 kits and Huztl in general - I read up a little here, now and then but don't post as much as I once did.

Alibaba is bigger than ebay and google and amazon combined, I don't do business there often but have found new vendors there in the past.

Farmertec, Arbortec, Huztl are all the same company, out of the same building, they have several other seller names on Ebay for other countries (which seems to violate the Ebay terms of service but...whatever).

All of the "manufacturers" putting bundles together will freely substitute a different part if they can find it cheaper or run out of their current stock, so never count on anything you read to be 100% accurate.

As @weimedog has shown there are at least 4 different big bore MS660 cylinders from Farmertec et al in the last year alone and if they get a better price on them you can bet there will be 4 more next year.

All the great info in this thread should serve as a guide, not as gospel for that reason.

Your individual business means little to these "importers", there are companies that spend $100K annually with Farmertec and we get the same mumbly mouthed half answers and excuses, the only places with enough clout to get things done are the HLSupplys, Baileys, etc of the world who buy multiple shipping containers of parts each month.

I have a race saw built on the Clone660 by a great builder and there were a handful of parts that didnt hold up to even rudimentary race testing.

He had me send an OEM piston, cylinder, circlips, piston pin, bearings (all), flywheel, ignition coil, crankshaft (this was before the good cranks were available from NWP in Taiwan, the FT cranks suuuuck), rope rotor and pawls, we also swapped to Caber rings for a little more compression.

I need to get that puppy out and make some videos with some of my other ported 1122s.

If anyone needs an earlier good 660 crankcase I think i have more than a dozen left in stock.

Capitalist Dave

Similar threads

- Replies

- 32

- Views

- 3K