mweba

Addicted to ArboristSite

This saw is an obvious Shindaiwa design all the way down to the trans caps. Four rubber body mounts, one nylon wrapped rubber handle av and rubber nipple limiters at the rear bottom.

500p by mweba1, on Flickr

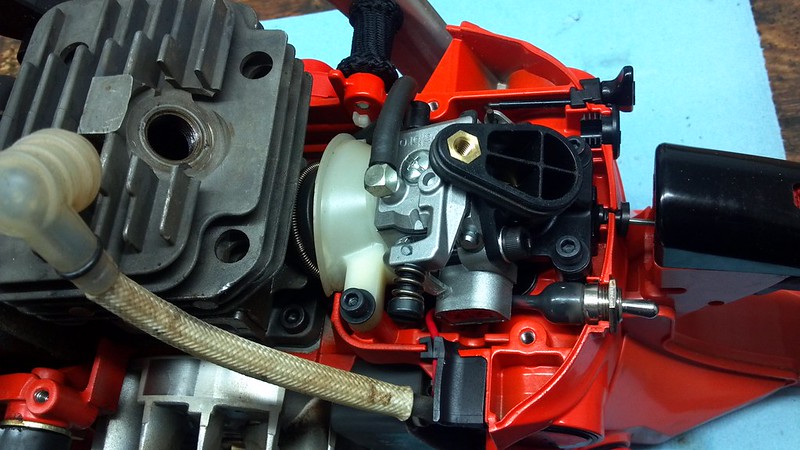

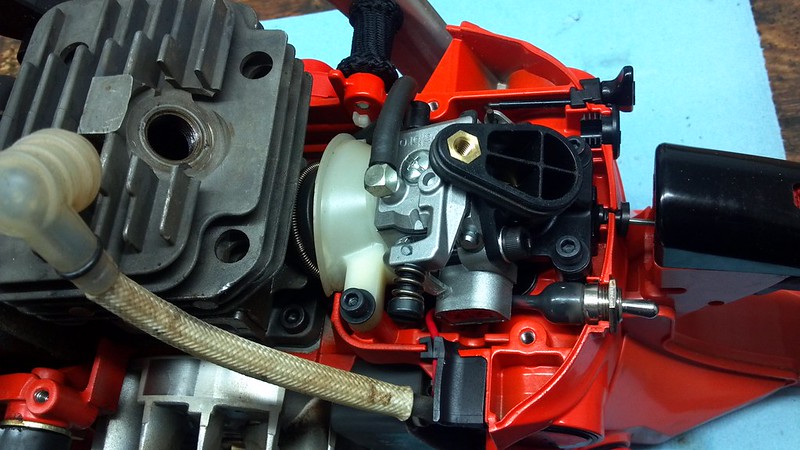

Walbro wt 106 rubber intake isolated.

500p intake by mweba1, on Flickr

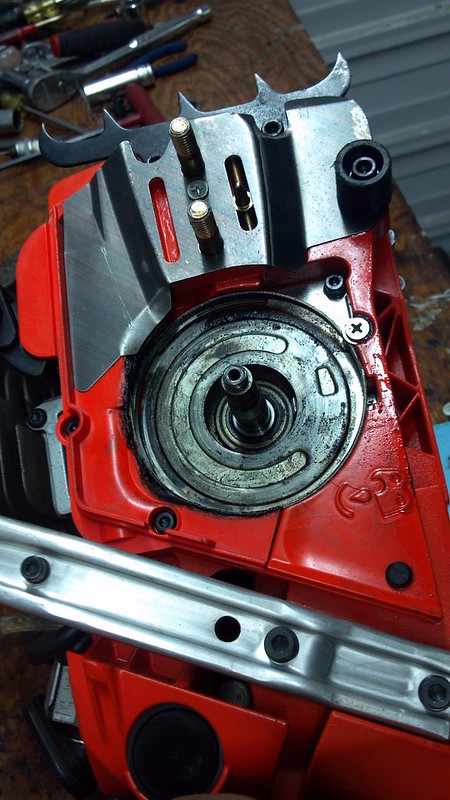

Inboard clutch with adjustable oiler

500p inboard by mweba1, on Flickr

Nice flock air filter that splits for cleaning. Also needs to be mentioned, the seems needs grease, other wise it leaks fines.

500p filter by mweba1, on Flickr

500p by mweba1, on Flickr

Walbro wt 106 rubber intake isolated.

500p intake by mweba1, on Flickr

Inboard clutch with adjustable oiler

500p inboard by mweba1, on Flickr

Nice flock air filter that splits for cleaning. Also needs to be mentioned, the seems needs grease, other wise it leaks fines.

500p filter by mweba1, on Flickr