It's been more than a year since I first ported my 260. It's been a great running saw that was fast enough to be fun at a GTG but still able to be used as a firewood saw. Back when I built the saw it was recommended that I install a bigger 044/046 carb since the carb and filter is such a bottle neck on the 260. To be honest with you, I didn't think it would make all that much difference. Boy was I wrong. I finished the basic work tonight. Here's what I did.

1. Enlarge hole through tank body for intake boot.

2. Replace carb studs with longer ones from a different saw.

3. Slot inside of carb box for clearance for needles.

4. Drill new hole for idle screw since it's in a different location.

5. Shorten idle screw so that it can slide in air box.

6. Remove choke from filter.

7. Enlarge opening into filter for much larger carb venturi.

8. Make provisions for choke to remain functional. I'm going to extend the rod on the lever out just past the surface of the plastic. I've already cut the slot in the plastic for it.

9. Mod a 038 intake elbow. The 260 is too small for the 044 butterfly and won't open. The 044 elbow is too big at the cylinder. A 034/036/360 elbow may work as well but I didn't have one to compare. I would still like to know the answer to this.

I haven't had it in wood yet, but I gained a LOT of RPMs. I've run this saw a fair amount so I know the saw. Before this carb swap, the saw turned 15,600. It had good torque and made a good saw that was fun at a GTG or to cut firewood with. It's now turning 16,500 with the filter and..........17,400 without it!!!!!!! That's the one that really shocked me. I didn't expect much change without the filter. I immediately knew it was way lean when I pulled the throttle. I had to go nearly a 1/2 turn richer to get it to 4-stroke. 17,400 still has a hint of 4-stroke! I was wondering what filter would run best for firewood use but I'm not interested in turning those kinds of RPMs in the woods. I'll just run the 260 Pro filter and tune it to about 16,300-16,500. This ought to be a whole different animal in a 8x8 with a good 16" 3/8 chain.

Not only that, it idles nicely and has great throttle response. I think I've gotten rid of most of the bottom end tuning issues I had before, as discussed in another thread here. I had to tune the bottom end on the lean side to keep it from loading up, but it has good throttle response there where as with the 260 carb did not.

As mentioned above, I ended up using a 038 intake elbow. I would have liked to have compared it to a 360 elbow but didn't have one. The cylinder side was just a hair oversized but tightened down very nicely without a hint of a wrinkle. You would never be able to do this with a 440 elbow. It's just way to big to just tighten down. The carb side is a little smaller than the 440 but the metal ring still fits in. The bar studs are indexed a little differently on the 038 so I had to cut the little notches in the rubber to go around them. I then had to enlarge the id of the metal washer that goes around the boot that prevents tightening the carb down too tight. It all fits nicely now. No leaks. I srayed carb cleaner around the cylinder/boot connection while it was idling.

I have one slight tuning issue. The notch cut out of the throttle butterfly is larger than it needs to be for a little 260. Because of that I can only get my idle down to about 3200. Factory spec is 2500 but the clutch isn't supposed to engage until 3600. I need new clutch springs. My chain is coasting at 3200. There no drag on the engine though when I set the brake. I'll order new springs tomorrow.

It was a lot of work, but I highly recommend this mod to anyone looking to take your 260 to the next level. I'm really anxious to get this thing in the wood.

I had to rotate the fuel line and bend it. Luckily it didn't break.

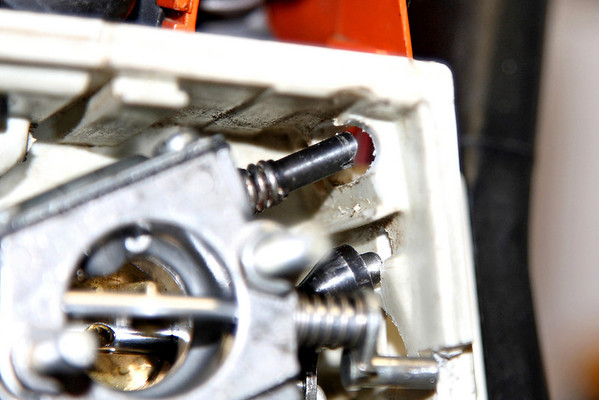

Here's the channel I had to gring to allow the needles to slide in. You can also see the shortened idle screw. I've got it screwed all the way out trying to get the idle down.

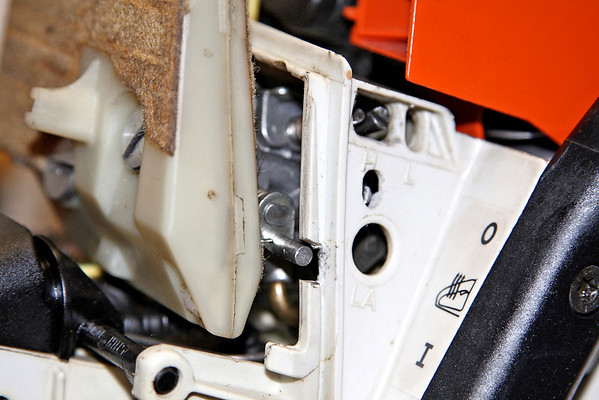

Here you can see the hole I added for the idle screw and the longer carb studs needed to reach the filter since the carb is thicker.

The choke rod to be extended.

Here's the slot where the choke will slightly stick out.

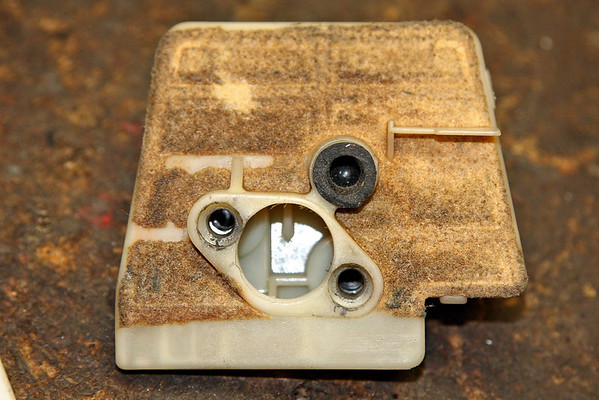

The air filter opening enlarged and choke removed.

It's a close fit with the plastic but it still fits.

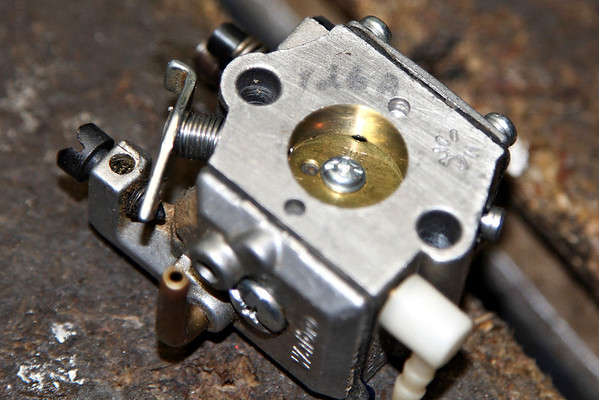

This is one of two tiny little notches in the butterfly plate of a 260 carb. You can see that the butterfly is still almost closed to achieve idle. I don't have a picture of a 044 butterfly, but the notch is a lot larger. I could try and peen it down but I don't want to mess it up.

. I'd only have to buy one carb?

. I'd only have to buy one carb?