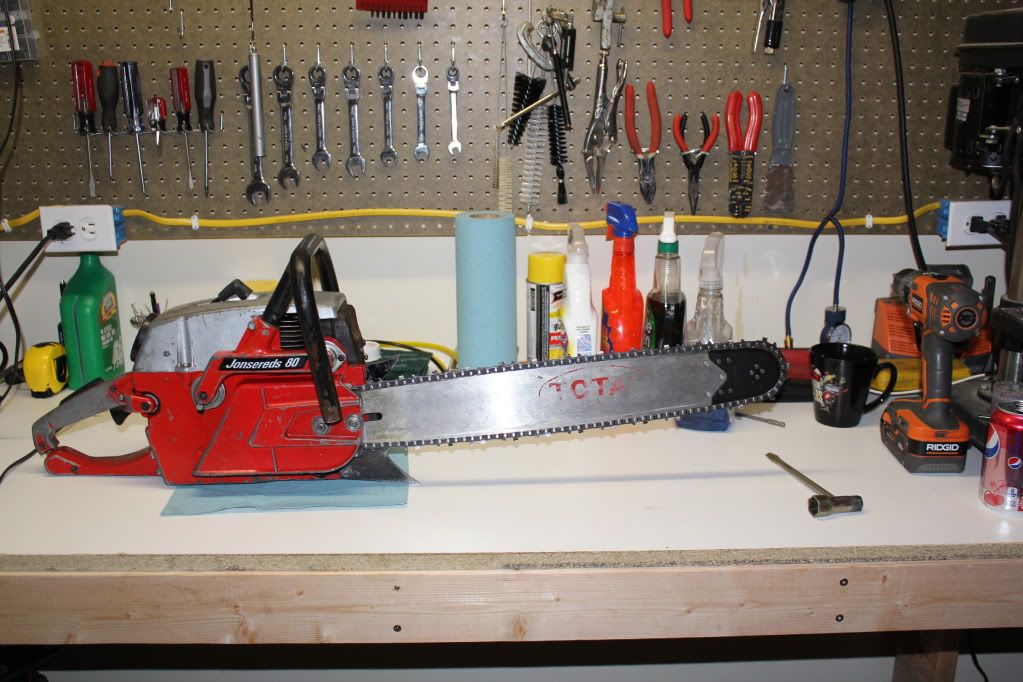

Jonsereds 80 Update

Got the new clutch side seal in, but still no luck popping the flywheel. For the time being I'm going to leave the flywheel side alone because my pressure and vac test came back perfect. As the old saying goes, don't mess with it if it ain't broke. I was affraid I was going to break something with all the pressure I had on the 3 way puller, and a handful of solid raps on the crank didn't break it loose.

After all that, saw fired with some priming but wouldn't run, come to find out I had the gasket and diaphram reversed in one side of the carb. After I got that fixed, she fired up and got her tuned in. I think I'm good to go, except, I need to make an exhaust baffle for the muffler.

PS: You better be committed when you pull the rope on these things, and even then it might not be enough to save your fingers from impending doom.

Thanks again for the help Cantdog, and I'll get some pics posted up when I get the tip replaced on the bar and the bar fitted on the saw. It will be wearing a total super bar that I got with the saw. Sounds like people have a lot of good things to say about Tsumura bars, I'm looking forward to finding out.

Saw runs like a champ, but the oiler isn't putting out any oil. I've got the screw out a couple turns and nothing. Pulled the strainer cap and everything seems to be intact. All hoses are connected as they should be. Any ideas or trouble shooting tips? Can I blow some compressed air through the line? Thanks

Saw runs like a champ, but the oiler isn't putting out any oil. I've got the screw out a couple turns and nothing. Pulled the strainer cap and everything seems to be intact. All hoses are connected as they should be. Any ideas or trouble shooting tips? Can I blow some compressed air through the line? Thanks