got my new piston & liner set in... but still trying to decide how to port.

shall I enlarge ports sideways or raise/lower ports?

if I enlarge sideways and not change timing... how far sideways?

.5mm or 1mm? don't want to go to large and have rings snag.

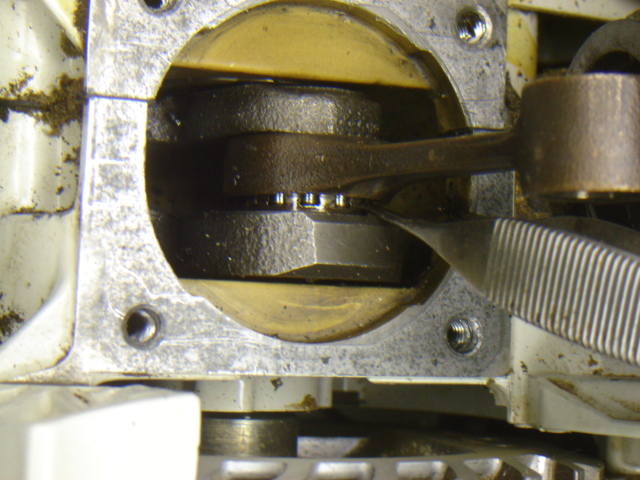

another issue that's still unresolved is ... are the big end bearing still in good condition?

will be taking a careful look for damage to edges of bearing cage. Sure don't want to put this together, only to have big end bearing failure.

a bit more detective work analyzing piston failure:

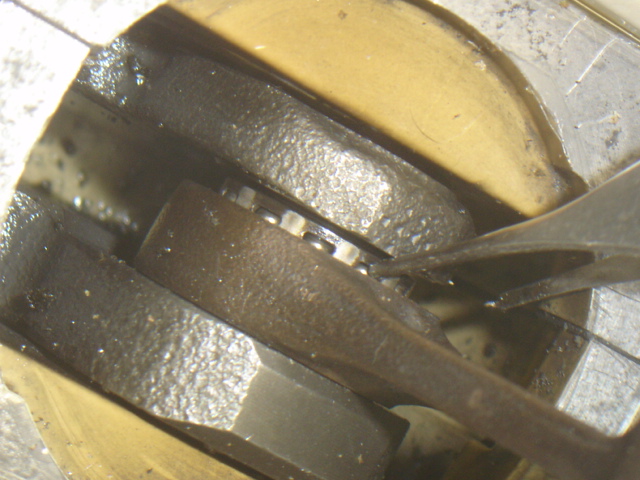

according to this new section at Madsen's I should see scouring on inside piston rod surface, if damage was caused by lack of oil in fuel with bearing surface dry.

http://www.madsens1.com/saw piston fail.htm

so far damage on piston indicates overheating, not damage from no oil in fuel.

--------------

small end bearing looks oily and undamaged

inside of piston pin is oily

inside piston side bearing surface show no scouring

other side also shows no scouring