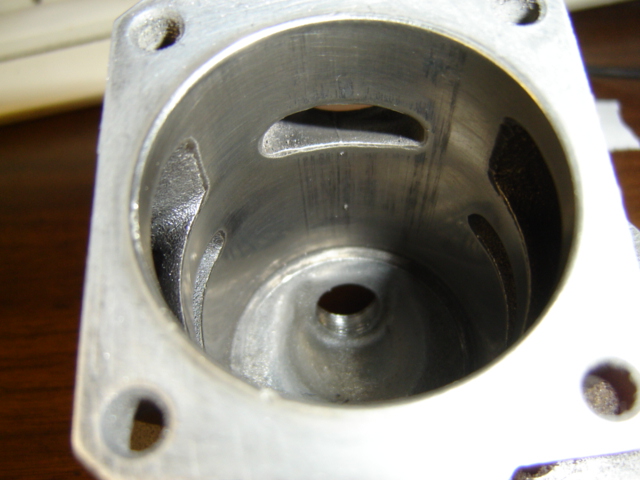

mine is super clean internaly and is barley broke in and doesnt even pull off 160

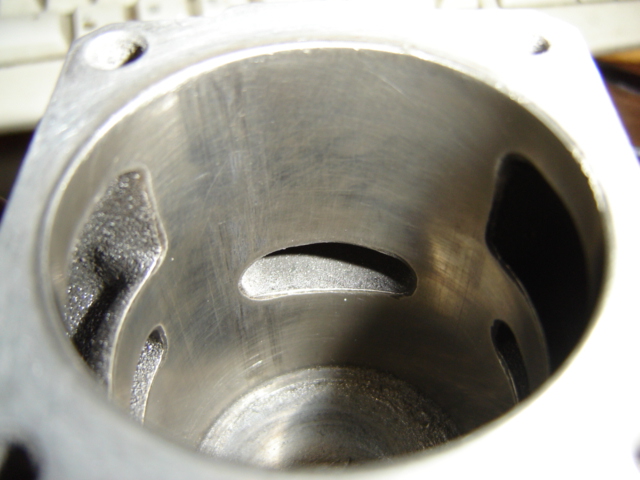

I tested mine last week, and it was just over 170. That surprised the hell out of me!

After I saw that, I grabbed my MS260 pro, and it was only in the 160's... I don't know if it's too new, or what, but I assumed the new saw would have higher compression than the old 026!