That's a lovely 700 Ed nice buy man. And yes thistle as long as us type people rescue these things before the wind up in the furnace

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

McCulloch Chain Saws

- Thread starter Bruce Hopf

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Umm at the moment -2 -4 C about the coldest it gets in the morning by the coast inland -10 and ruthless frosts and snow is normal and if the sun comes out it mite make 10 or 15c during the day at the warmest. If a southerly whips up it will feel like 0 all day as the southerly comes straight from Antarctica. Daylight at 8am dark at 5:30. Other than short days it's a nice time to be cutting last year I got heat stroke cutting in 35c so yeah if it's too hot then it's too hot

Feels like 100 degrees here in sunny South Carolina.

Man,35C is 100 F.Yeah,that's definitely too hot to be cutting! I can understand why/how you got a heat stroke.I've cut when it was 30C. or 90F.here & that' was brutal.I did some cutting here last week when it was 85F or 27C.& it was very uncomfortable,especially with high humidity.Normally I don't cut in the summer months if I can help it,but when free wood comes along I make an exception now & then.

Ed

Ed

Man,35C is 100 F.Yeah,that's definitely too hot to be cutting! I can understand why/how you got a heat stroke.I've cut when it was 30C. or 90F.here & that' was brutal.I did some cutting here last week when it was 85F or 27C.& it was very uncomfortable,especially with high humidity.Normally I don't cut in the summer months if I can help it,but when free wood comes along I make an exception now & then.

Ed

Your 700 looks pretty nice Ed. I call that saw cake chainsaw undercoating.

Great units.

Up til 2017 I'd cut 2-3 days every month when I had the spare time.Even if it was 90+ degrees in July-August and didn't really need the wood (try to keep 2-3 yrs ahead all the time).

But not anymore,I think all the years of working heavy construction plus part time tree work is finally catching up to me.I've passed up a few decent free wood scores in recent weeks mainly cause I'm getting tired now,plus not much extra storage space left.I did cut a couple big pickup loads worth in late April when part of a huge Silver Maple came down early one morning during a storm 3 houses south of me.Still have about 2/3rds left to split/stack.Its anywhere from 14" to 30" plus.I'm no rush,thats a big change from a few years ago haha.

But not anymore,I think all the years of working heavy construction plus part time tree work is finally catching up to me.I've passed up a few decent free wood scores in recent weeks mainly cause I'm getting tired now,plus not much extra storage space left.I did cut a couple big pickup loads worth in late April when part of a huge Silver Maple came down early one morning during a storm 3 houses south of me.Still have about 2/3rds left to split/stack.Its anywhere from 14" to 30" plus.I'm no rush,thats a big change from a few years ago haha.

joeymt33

I bleed YELLOW!

I think the variations in the automatic oil pump are related to how well the phenolic diaphragm fits in the bore of the pump body, the better the fit the more efficient the pumping action with the change in crankcase pressure/vacuum.

Joey - I ran into a similar issue on the Mini Mac automatic pumps. It was all related to how far the metal insert was pressed inside the pump body, it the holes didn't align properly the oil could not pass and it would pressurize to the point it locked up. Worked fine out of the saw since you (I) was moving the piston by hand and going past the opening with the small metal rod (piston assembly) but in the saw it would not work. I was reminded of a Service Bulletin I saw that described exactly how far the insert was to be pressed in (apparently a number of units left the factory with the inserts improperly positioned) and I finally took a close look at it. The 10 Series plastic body pumps have a similar insert so I suppose it is possible for them to be incorrectly positioned. Pull that one back out of the trash can and see if you can see anything amiss.

First photo show the Mini Mac automatic pump "exploded view"

View attachment 744304

Second photo shows the insert inside the plastic body on the 10 Series pump

View attachment 744305

Mark

Great info Mark and thank you. I should have reached out earlier.

I was already pissed working on my Mini Mac that I use so much. The coil died in it and so I converted it to the older points coil/flywheel/points. (I had no late model coil on hand) Then after attempting to run it the saw died again and this time the Welch plug came loose in the carb. So after that I little patience to work on the P700.

Thanks again mark.

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$29.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

matt_lamb_160

ArboristSite Operative

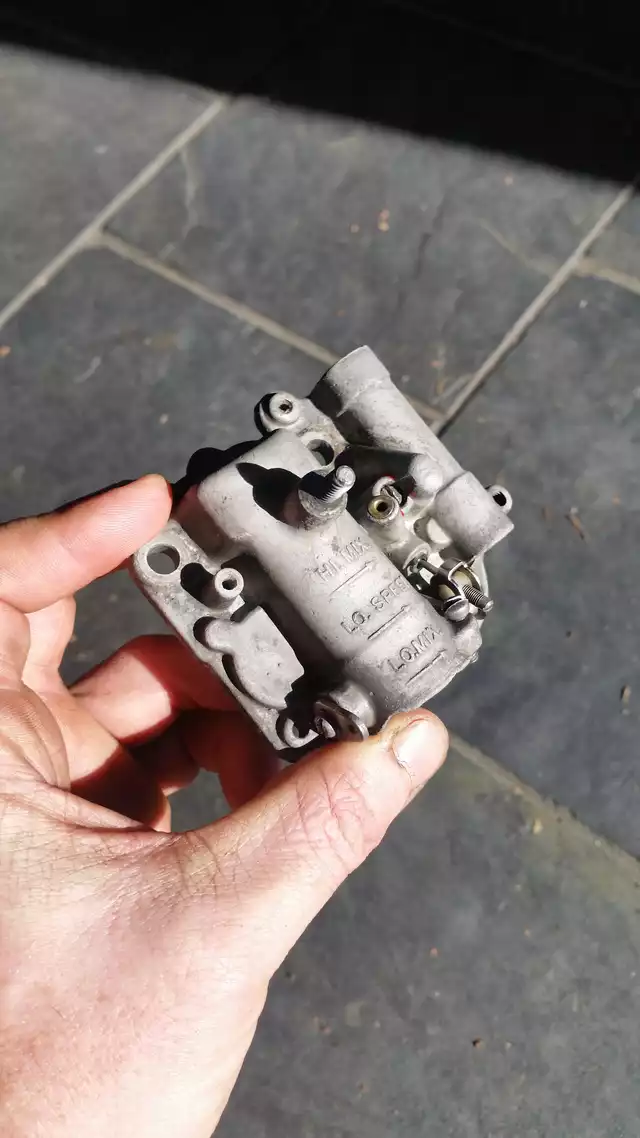

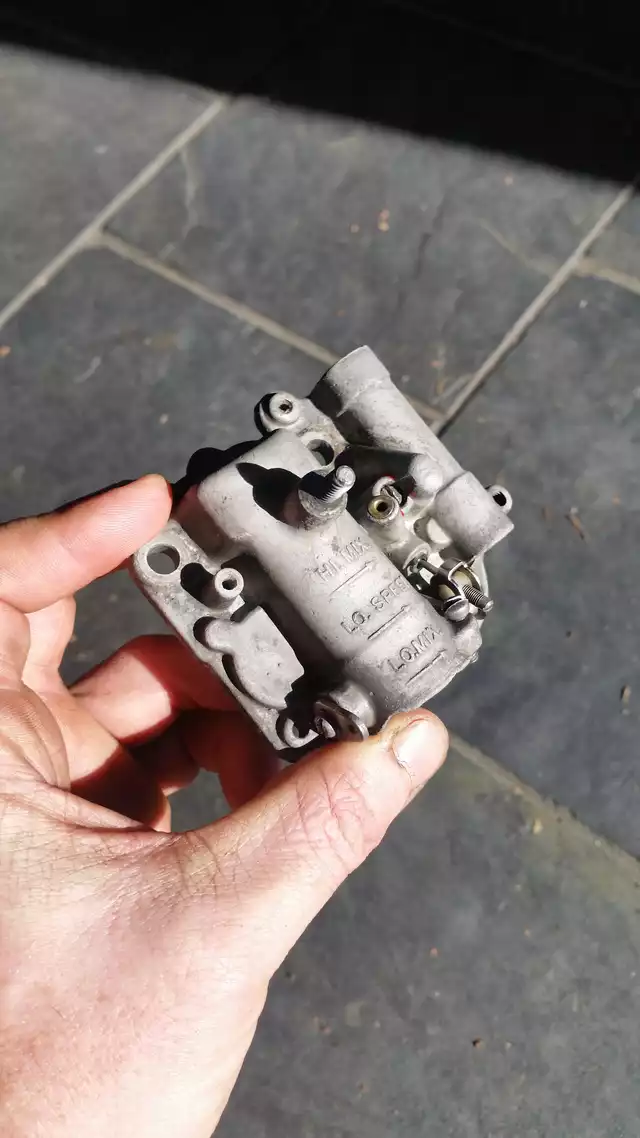

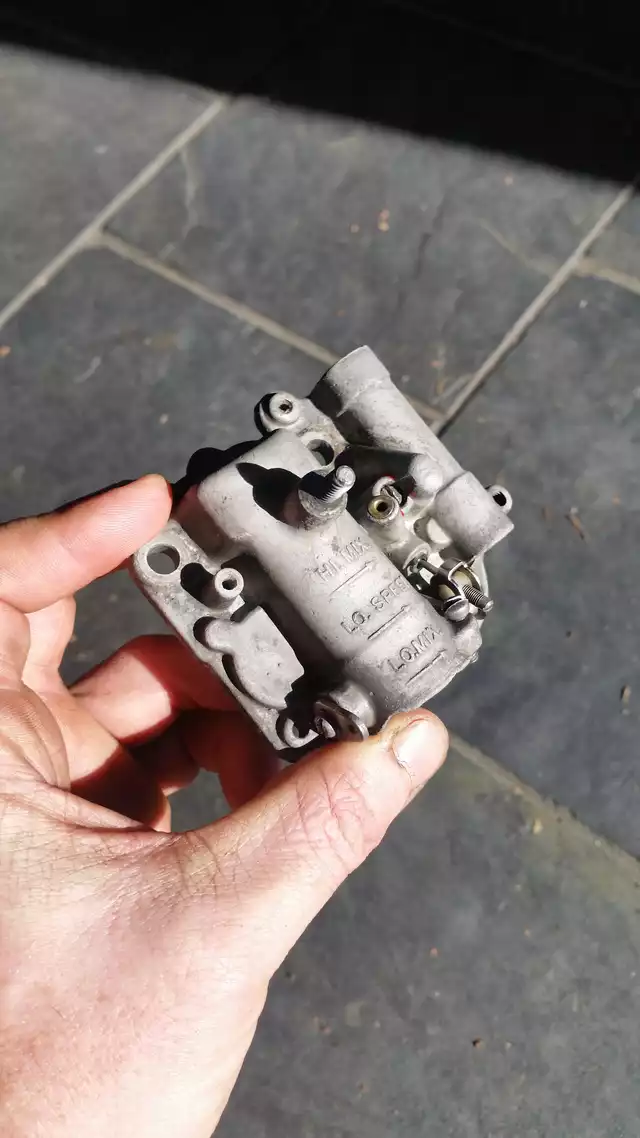

Jethro 2t sniffer suggested that I post my 3-10E here. It is mising a few bits and pieces, some are in the mail heading my way including a coil, carb diaphram and pull start recoil spring. I am still missing a check ball and seat and a duckbill for the bullfrog to get the primer working. The battery pack as well as a few other piece for the electric start are long gone but I am not too worried about that.

Here it is pulled apart for cleaning etc.:

And here is is when I got it:

If anyone has an unwanted bullfrog in this configuration, I may be interested if it is complete:

Here it is pulled apart for cleaning etc.:

And here is is when I got it:

If anyone has an unwanted bullfrog in this configuration, I may be interested if it is complete:

Jethro led you in the right direction. You will find some great help here. I wish i could help you but ive not messed with any of those type carbs nor do i have parts. Someone should eventually though. Be patient.

I have an aquaintence that i send messages back and forth with when we get new saws. He has a working 3-10e. Its really neat how it starts. Good luck and keep after it.

I have an aquaintence that i send messages back and forth with when we get new saws. He has a working 3-10e. Its really neat how it starts. Good luck and keep after it.

Hey Joey,I've got a nice bullfrog carb that came off a 2-10.If my memory serves me correctly it looks just like the one in the pic.I know there were a couple different styles (one screw & two screw).I'll see if I can hunt it up for you,it might take a while to locate it.

Ed

Ed

New points in the 1-41 fired right up with prime ,joy!..

Now I have to rebuild the HL87C.

Now I have to rebuild the HL87C.

matt_lamb_160

ArboristSite Operative

Thanks Ed, I'll be interested to see what you have.

Jethro 2t sniffer suggested that I post my 3-10E here. It is mising a few bits and pieces, some are in the mail heading my way including a coil, carb diaphram and pull start recoil spring. I am still missing a check ball and seat and a duckbill for the bullfrog to get the primer working. The battery pack as well as a few other piece for the electric start are long gone but I am not too worried about that.

Here it is pulled apart for cleaning etc.:

And here is is when I got it:

If anyone has an unwanted bullfrog in this configuration, I may be interested if it is complete:

Well ya found the place Matt jolly good bunch of gents here. Welcome to the mac addiction

matt_lamb_160

ArboristSite Operative

Thanks mate, I can definitely understand the attraction to these saws, particularly the early ones. I also have a PM470 (bad photo of it below). I put a Chinese bar on it just to get it going, but I have a McCulloch bar on the way.

I've got a 7-10A that I've been fiddling with off & on since Feb.when I bought it.I rebuilt the carb & couldn't get it to fire up even though it had spark.I also put a new fuel line & filter on it & gave it a new plug.A couple of weeks ago I cleaned the points & gapped them at .019,still no fire.I checked the coil & it only has 1940 ohms.I checked a 10-10 coil & it was reading 9400 ohms.Bothe of the coils are points coils.Can I change out the 7-10 coil & put the 10-10 coil on?

Ed

Ed

All of the points coils should be the same so yes, you will be able to swap out a good 10-10 coil for the one in your 7-10.

Mark

Mark

Thanks Mark,much appreciated!

Ed

Ed

How do you check if the coil is goodI've got a 7-10A that I've been fiddling with off & on since Feb.when I bought it.I rebuilt the carb & couldn't get it to fire up even though it had spark.I also put a new fuel line & filter on it & gave it a new plug.A couple of weeks ago I cleaned the points & gapped them at .019,still no fire.I checked the coil & it only has 1940 ohms.I checked a 10-10 coil & it was reading 9400 ohms.Bothe of the coils are points coils.Can I change out the 7-10 coil & put the 10-10 coil on?

Ed

Sent from my SM-G920V using Tapatalk

I have a multi meterHow do you check if the coil is good

Sent from my SM-G920V using Tapatalk

How do you check with a multi meterI have a multi meter

Sent from my SM-G920V using Tapatalk