The fittings should be waiting when I get home tonight, I will try to remember and put a couple together for show.

Mark

Mark

Forgive me if this has been covered before, but I am beginning to believe that the ten series oiler is just not quite up to the new oils. Due to $, I recently switch from Stihl bar oil to Poulan and at the same time I concluded that due to pump leaks I have probably been burning more oil than was getting to the bar. I never really thought about it as the mix and oil always seemed to be synchronized. Now that I have been working on the leaks, I am not using any oil unless I manually oil. Anyway, I couldn't believe the vacuum it took to suck the oil out of the tank with a syringe and then the pressure to empty it. The oiler works with the mineral spirits I put in the tank to loosen things up a bit. Would it help if I opened the screw up? Any comments on converting back to 30W? (A misnomer there as I used used motor oil for 25 years before I got educated about such things). Ron

Hey Ron - Here's a LINK to Mark's thread on 10 Series oilers.

I would run it with the mineral spirits to maybe clean it out a bit. Loosen up the screw some .... Nope, don't go back to motor oil. Personally, I use the stuff at Tractor Supply all year and have no complaints.

I second the TSC bar oil. They sometimes put it on sale for around $8 a gallon.

Have you guys had any luck with the mineral spirits? I've never tried it, but it would be nice to have a quick fix.

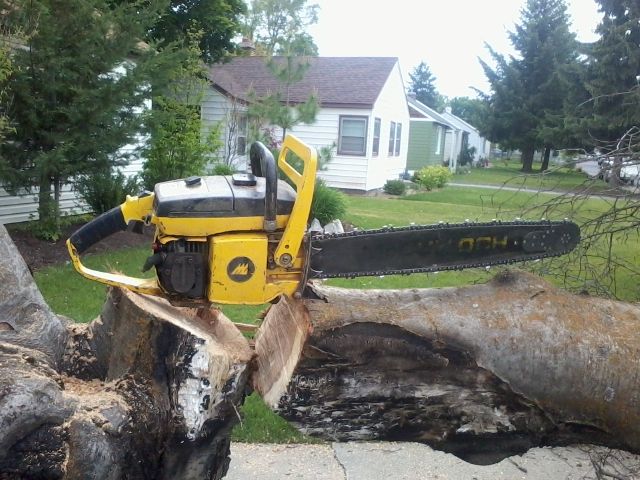

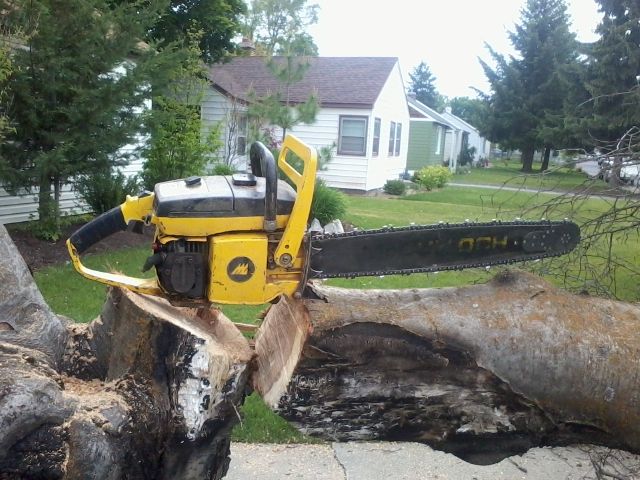

Yesterday was the first time I ran a 10-10 for a considerable amount of time. Before yesterday, it was cookie cutting and small jobs. I had a Maple tree blow down and decided to use a 10-10 20" to cut it up. I must say was impressed with it for it's size. It did better than I thought it would and sounded great. :msp_thumbup:

I've had a CP70 rebuild project going on for over a year now. Had the jug bored 30, new piston kit, bearings and seals.

I have all the parts.... now I can't wait to get it finished.

A friend of mine found this in the back of a storage container, while doing some clean up at his yard. Looks like I'll have my first RH start Mac, this afternoon.

It's hard to tell from the pics but that saw may have been used just a little bit. Hopefully it will look better when you clean it up.

I second the TSC bar oil. They sometimes put it on sale for around $8 a gallon.

Have you guys had any luck with the mineral spirits? I've never tried it, but it would be nice to have a quick fix.

Thanks, guys. I assume TSC is not as "thick" as the others. I checked the link to Mark's thread, although he doesn't get into oils he does mention using mineral spirits. I just used mineral spirits because I had it on hand. BTW the 800 owners manual says to use MAC bar oil, of course, and if not available then non-additive sae 30 motor oil above 40 degrees F (5 C) and above and sae 10 below. Ron

A little something to get you going.

.png)

.png)

I was messing with a few saws last night, getting ready for some firewood on Sunday.

Is it just me or is a sp81 (full wrap, no brake) lighter than a pm700 (half wrap, with brake)? I don't have a scale, but it sure felt that way. Maybe I was just feeling the effects of he Yellow Fever?

Yesterday was the first time I ran a 10-10 for a considerable amount of time. Before yesterday, it was cookie cutting and small jobs. I had a Maple tree blow down and decided to use a 10-10 20" to cut it up. I must say was impressed with it for it's size. It did better than I thought it would and sounded great. :msp_thumbup:

I've had a CP70 rebuild project going on for over a year now. Had the jug bored 30, new piston kit, bearings and seals.

I have all the parts.... now I can't wait to get it finished.