A previous thread mentioned dust getting inside the airfilter housing.

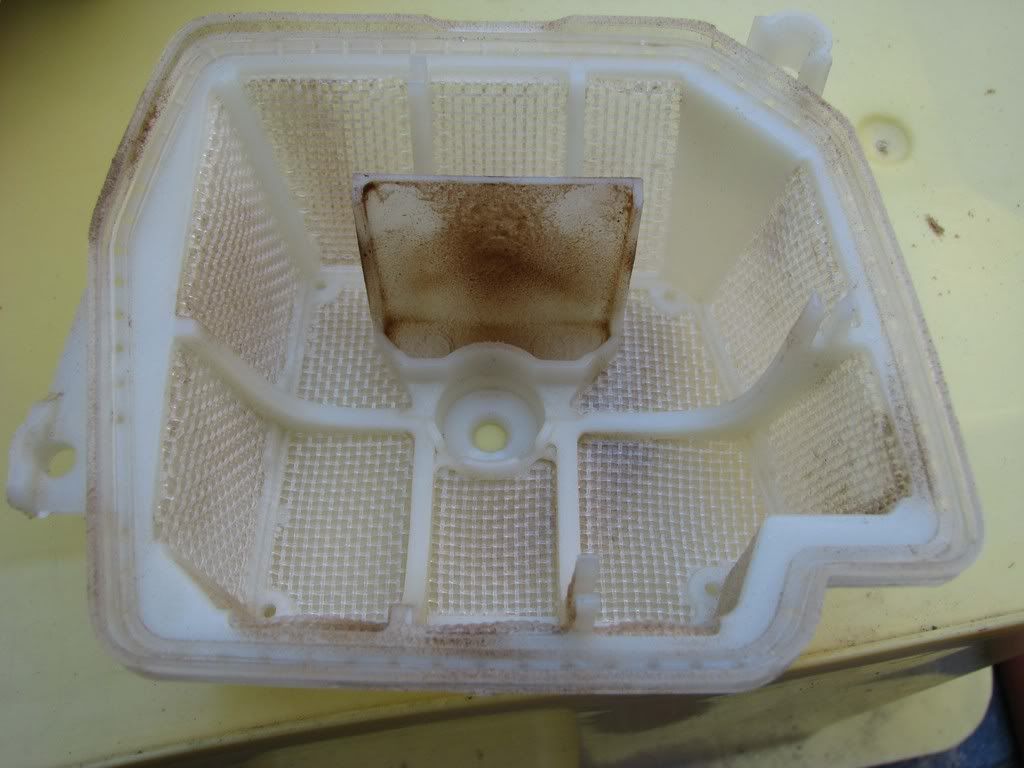

I checked my 361 accordingly and found a lot of sawdust.

THIS LOOKS AS AN OEM DESIGN FLAW SO ALL 361 SHOULD BE AFFECTED CHECK YOURS ACCORDING MY PICTURES!!!

My 361 is in its 15th tank only and i can scrape the dust from the inside at the throttle butterfly. HELP

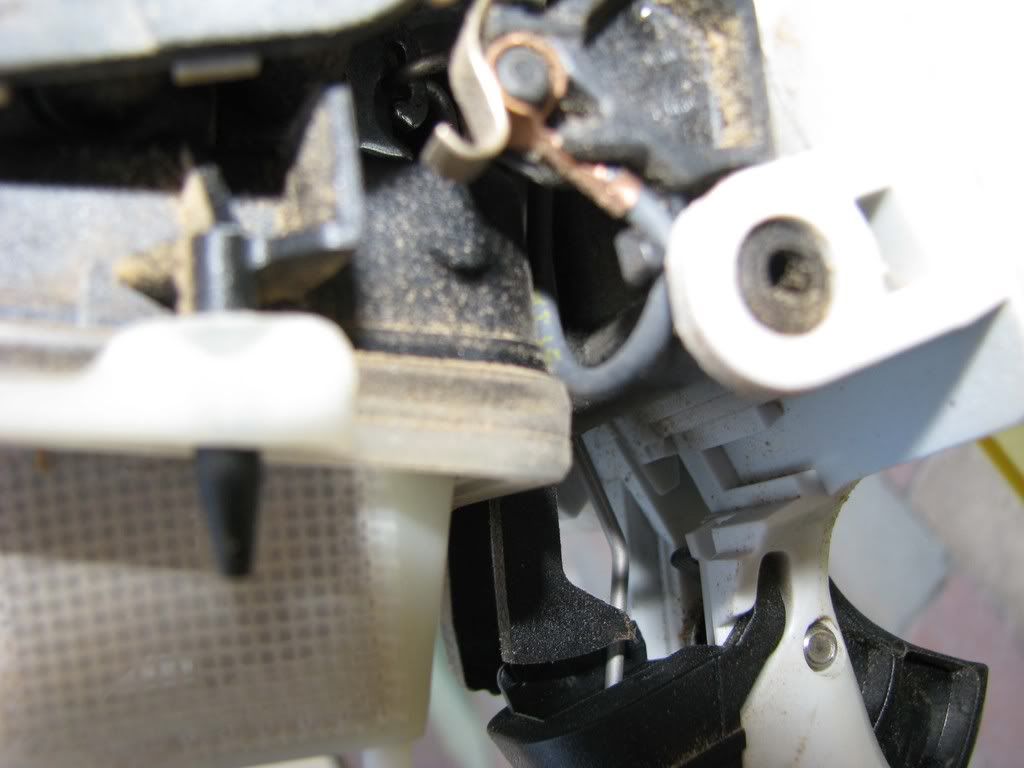

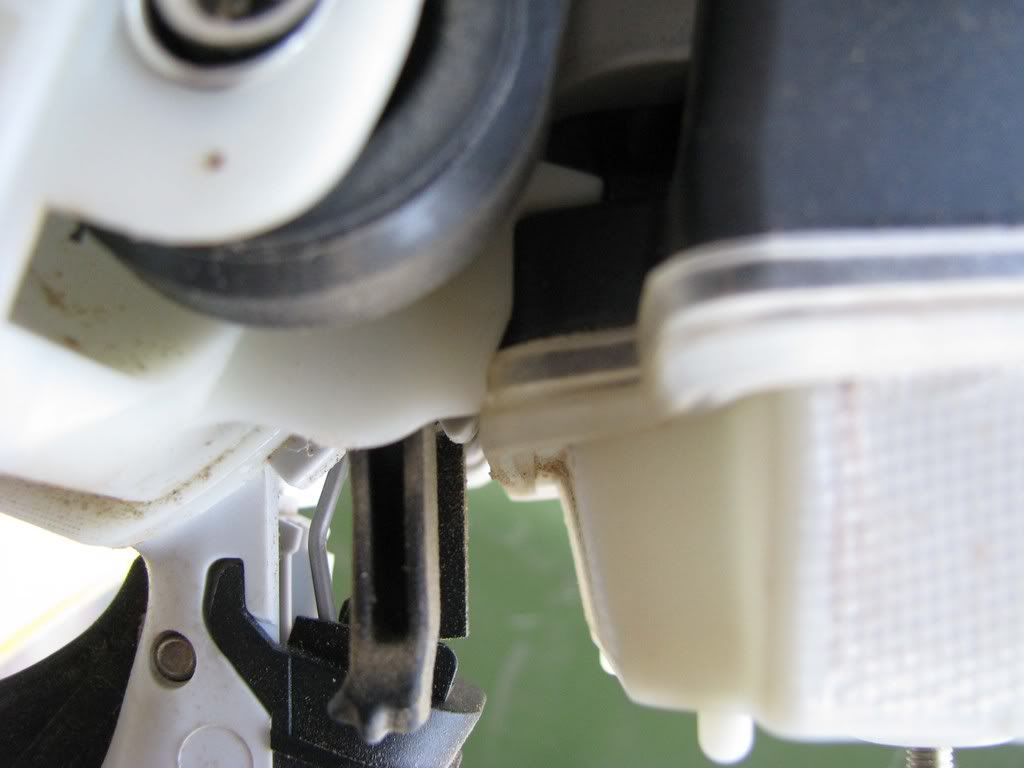

It looks as the white filtercap is too weak and is bending at the bottom side. You can clearly see the areas where the dust is passing the silicone seal.

Experts and Stihl dealers: how much damage is done? Advise please.

What would Stihl say about this? I will not jump over my dealer his head but first see what he is able to do about this.

I can see an easy mod to avoid this problem for all of you.

Take a dremel or file and take off part of the tank fins which are near the bottom side of the filter.

Another thing i have to check out is the support plate inside the white filter. This plate prevents the filter to be pushed to deep but i suspect that shaving off a mm will increase the pressure on the seals and avoid the problem.

I checked my 361 accordingly and found a lot of sawdust.

THIS LOOKS AS AN OEM DESIGN FLAW SO ALL 361 SHOULD BE AFFECTED CHECK YOURS ACCORDING MY PICTURES!!!

My 361 is in its 15th tank only and i can scrape the dust from the inside at the throttle butterfly. HELP

It looks as the white filtercap is too weak and is bending at the bottom side. You can clearly see the areas where the dust is passing the silicone seal.

Experts and Stihl dealers: how much damage is done? Advise please.

What would Stihl say about this? I will not jump over my dealer his head but first see what he is able to do about this.

I can see an easy mod to avoid this problem for all of you.

Take a dremel or file and take off part of the tank fins which are near the bottom side of the filter.

Another thing i have to check out is the support plate inside the white filter. This plate prevents the filter to be pushed to deep but i suspect that shaving off a mm will increase the pressure on the seals and avoid the problem.

Last edited: