Rooshooter

ArboristSite Operative

MS880 sucking dust

It would appear that not only the 361 but quite a few model Stihl saws have air filtration ( or lack of it ) problems.

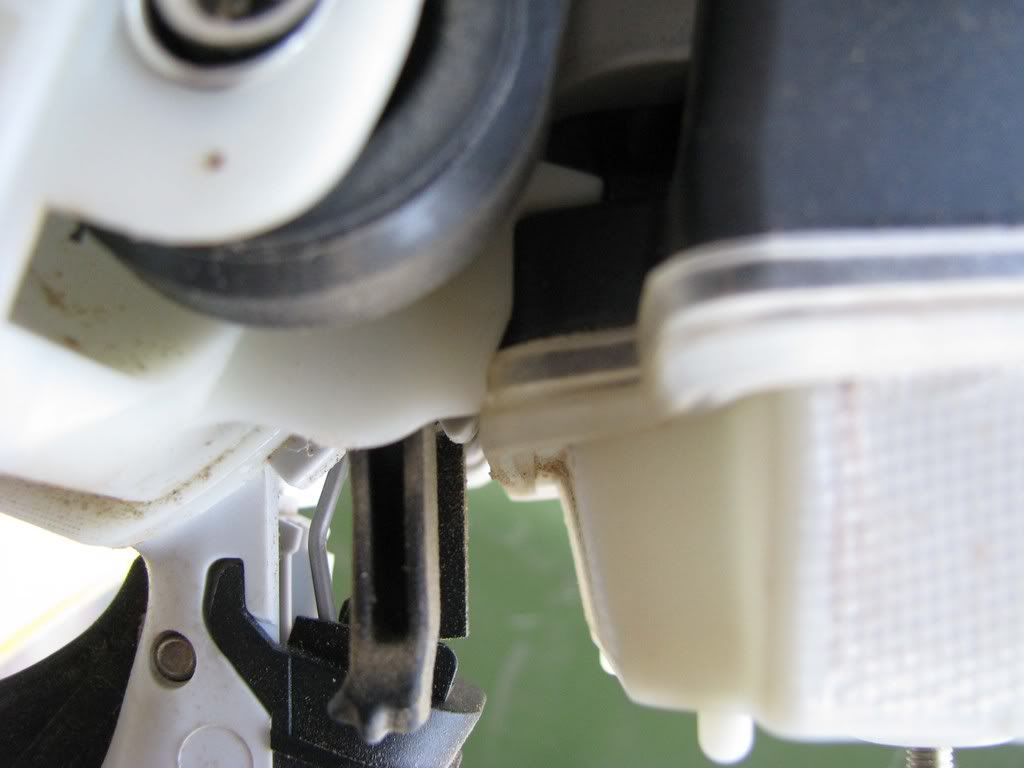

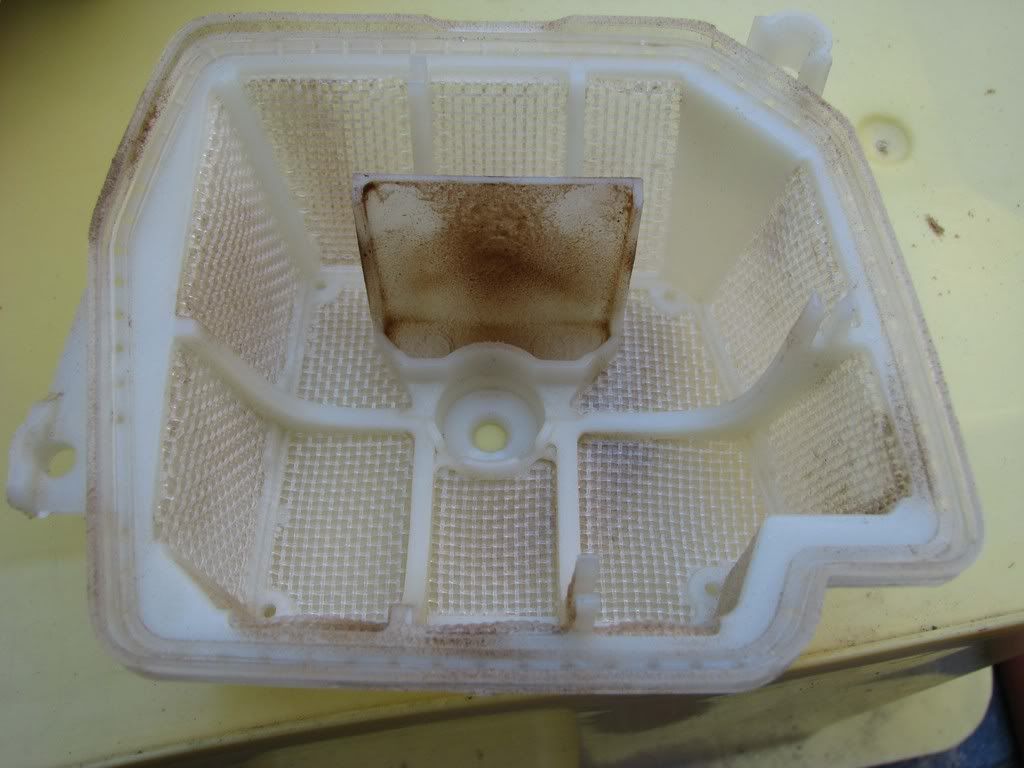

I have seen problems on the MS460, 660, & 880 and have an 880 myself which has had major problems with dust bypassing the airfilter at the filter base - my saw has a filter with the felt pre filter and no dust gets through the filter itself.

It would appear that a change of airfilter by the Stihl factory which seems to have an excessively hard base combined with a hard plastic plate the filter mounts against is is the cause of the problem.

I have spoken to the warranty & service manager at Stihl Australia and he admitted that Stihl were aware problem, but tried to tell me that it was more noticeable during the last few years whilst we were in one of the worst droughts on record and conditions were drier, What a load of bulls**t !

In any case when I started using the saw the problem was noticed almost immediately and the log I was blocking up had a 30 - 32% moisture content so it certainly was not dry.

When my saw was pulled down scoring was noticed on the cylinder bore and polishing on the piston skirt. The saw had only been operated for 15 hours at this stage, I would also imagine that a good quantity of sawdust got into the crank case & bearings. The saw was also sent to Stihl Aust and the service manager told me it was normal wear - What a load of crap.

I have not finished with this as yet and will go to consumer affairs about it as the local dealer that inspected it prior to being sent to Stihl said it would need a piston & cylinder replacement which has not been done.

Stihl have supplied a severe service filter kit for the saw however the rear cover can not be used when fitted.

In my opinion a p*ss poor effort by Stihl on the largest commercial chain saw now available AND ONE UNHAPPY CUSTOMER

A previous thread mentioned dust getting inside the airfilter housing.

I checked my 361 accordingly and found a lot of sawdust.

THIS LOOKS AS AN OEM DESIGN FLAW SO ALL 361 SHOULD BE AFFECTED CHECK YOURS ACCORDING MY PICTURES!!!

It would appear that not only the 361 but quite a few model Stihl saws have air filtration ( or lack of it ) problems.

I have seen problems on the MS460, 660, & 880 and have an 880 myself which has had major problems with dust bypassing the airfilter at the filter base - my saw has a filter with the felt pre filter and no dust gets through the filter itself.

It would appear that a change of airfilter by the Stihl factory which seems to have an excessively hard base combined with a hard plastic plate the filter mounts against is is the cause of the problem.

I have spoken to the warranty & service manager at Stihl Australia and he admitted that Stihl were aware problem, but tried to tell me that it was more noticeable during the last few years whilst we were in one of the worst droughts on record and conditions were drier, What a load of bulls**t !

In any case when I started using the saw the problem was noticed almost immediately and the log I was blocking up had a 30 - 32% moisture content so it certainly was not dry.

When my saw was pulled down scoring was noticed on the cylinder bore and polishing on the piston skirt. The saw had only been operated for 15 hours at this stage, I would also imagine that a good quantity of sawdust got into the crank case & bearings. The saw was also sent to Stihl Aust and the service manager told me it was normal wear - What a load of crap.

I have not finished with this as yet and will go to consumer affairs about it as the local dealer that inspected it prior to being sent to Stihl said it would need a piston & cylinder replacement which has not been done.

Stihl have supplied a severe service filter kit for the saw however the rear cover can not be used when fitted.

In my opinion a p*ss poor effort by Stihl on the largest commercial chain saw now available AND ONE UNHAPPY CUSTOMER

)

)

i was cutting up old pine construction wood all day and had to stop as the nails won from my chains...:censored:

i was cutting up old pine construction wood all day and had to stop as the nails won from my chains...:censored: