dlabrie

ArboristSite Member

1600cc s would throw a lot of sawdustSell it??? Are you serious??? That engine would be perfect to replace that Honda on the mill.

1600cc s would throw a lot of sawdustSell it??? Are you serious??? That engine would be perfect to replace that Honda on the mill.

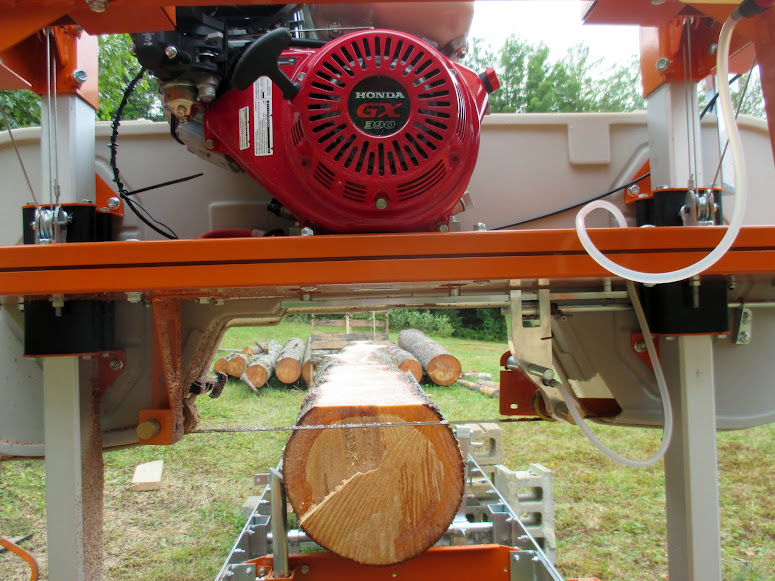

The next day, as i was cutting deeper into the cant, I hit another one! I just caught the tip of this on and was able to keep cutting. I will change the blade on jmy next log.Sir, I'm slightly jealous a new mill, room to mill, and a tractor!Just picking, congrats on the setup. Once you get your mill shed built you'll have no problems with it being on a slab.

I like your idea as well, a 2x10 would prob be plenty strong supported at 4' OC, maybe a 2x6 nailed as a beam would be bit stronger and give you a thicker area to lay your posts. 2x6 you could use smaller logs if needed to save better stuff for the building. Nice pics and sorry to see you ran into some metal. Is that a screw? I wonder how that got into the tree. I've been lucky to not have run into something so far. Maybe now that you've hit something right off the bat you won't have that issue for quite a while.

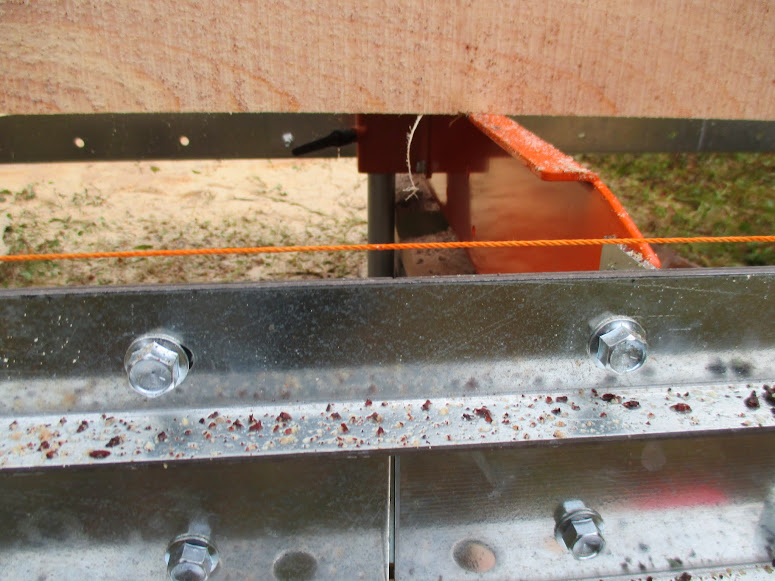

The 1/2 " dip was in the middle of the track. I loosened the bolts at the rail joints and lifted them to get it level/ That took care of it.Before I got the trailer package, I had my mill set up much like yours. I used wedges to fine-tune the track, and that worked fine. My concern is that the dip in the track does not explain the 1/2" variation in your cant. The most obvious is to make sure there was no debris on the crossbunks lifting one end of the cant. Run the string along the crossbunks. They should have the same dip as the track. Which end was high? Did you have your mill set to cut 6" or 6-1/2"? Assuming you wanted 6" thick, did you try making a second leveling cut? Did you watch carefully for any movement in the cant due to stress in the wood? Finally, did you get this variation after hitting the drywall screw? Even if the saw continues to cut, it will mess up the set in the blade, and it will cut every way but straight. Try it with a fresh blade (even if you didn't hit the drywall screw before the problem). Finally, re-check the adjustment on the blade guides.

As you may have guessed, there are a lot of variables involved in milling. The trick is to narrow down the cause of any problems. Checking the track for straight was a good start. Let us know what you find out.

Good deal, and was wondering when you get around to doing more milling and building will there be pics to follow? Not sure how time consuming it is for you to get your pics uploaded or if being so busy you'll even have time with the building, but if you're up for it many guys would like to see the progress of your milling and building. It's always nice to see more posts/build threads on here. Don't have to go too detailed, just a pic here and there. Might give others some ideas on how to setup a milling area and so forth. Also, if you ever have any carpentry questions lots of knowledgeable guys on here. I'm a carpenter myself and just love talking about building. Take care and enjoy the mill.

Also, was wondering if you'd be putting the shed up green? I see you have your piers in place, one step closer. How deep is frost line in NH? Here we're going 42" give or take. I use a skidsteer with a 12" bit and usually do 8" x 48" and bell the bottom out to 15" on any good size deck or structure if soil is silty or poor drainage.