TreeJunkie

ArboristSite Guru

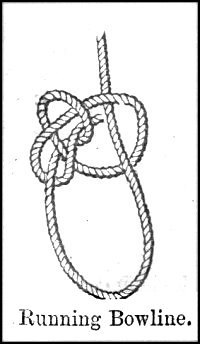

Some guys who i work w/ have gotten into the habit on the ground lines: which have spliced eyes;placing a steal biner 50kn and using this as a faster way to connect w/ rather than using a running bowline or the like.....THis seems fine to me in some situations>.However it does worry me when lowering heavier material. B/c of the way the load is applied, i don't think the biners are intended to be loaded this way....

I do like the idea that by using a spliced eye you are keeping a greater amount of your SWL;by avoiding using a knot...

Does anyone have any suggestions or Thoughts on this???

I do like the idea that by using a spliced eye you are keeping a greater amount of your SWL;by avoiding using a knot...

Does anyone have any suggestions or Thoughts on this???