Not sure who made the ones in the past, but there's always a chance. Who knows, I may have one down there I wasn't aware of too lol.It's my understanding that Sugi makes the lightweight bars for Husqvarna, so maybe you have had one? lol.

SR

I do have a very odd older husky labeled Oregon lightweight bar, it's a 93dl by

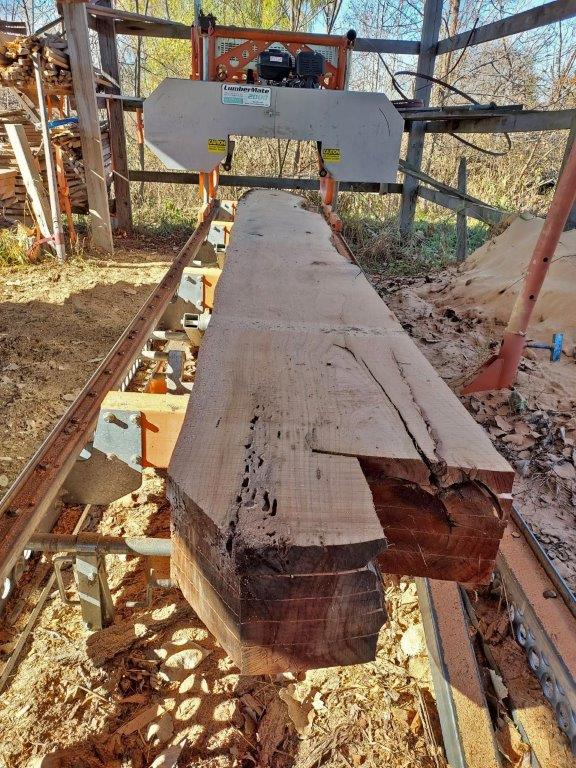

063. I think it was an error, I got a steal of a deal on two of them from a guy I met on Craigslist about two weeks after I tried to buy some on ebay myself. He and I are still good friends. He does a lot of chainsaw milling, he has a bunch of 120cc saws and some very large bars. He had a set of long aluminum tubes and a couple pieces of scaffolding that had tabs welded on every 3", he would set the log in place and level it up, then set the tubes onto the scaffolding. Cool setup.