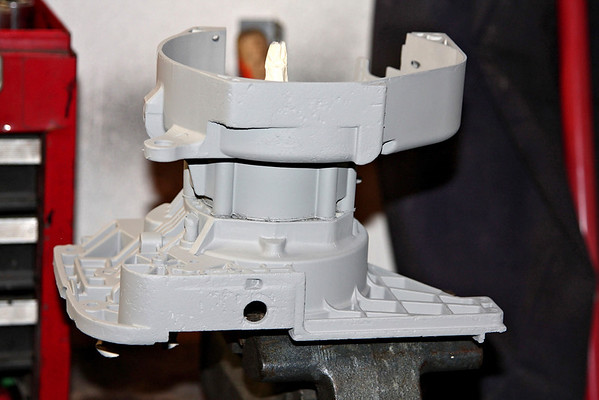

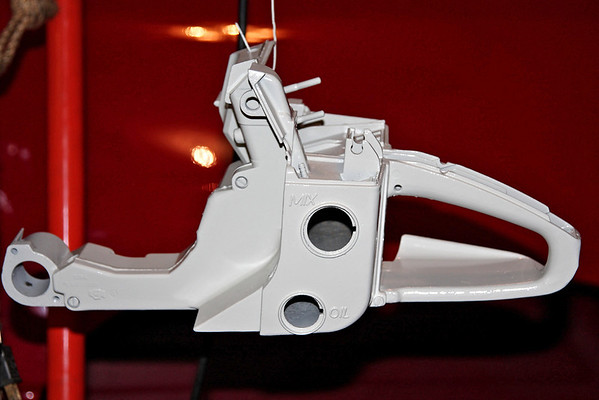

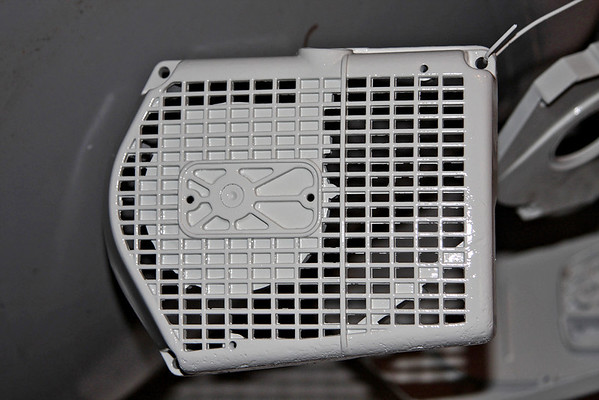

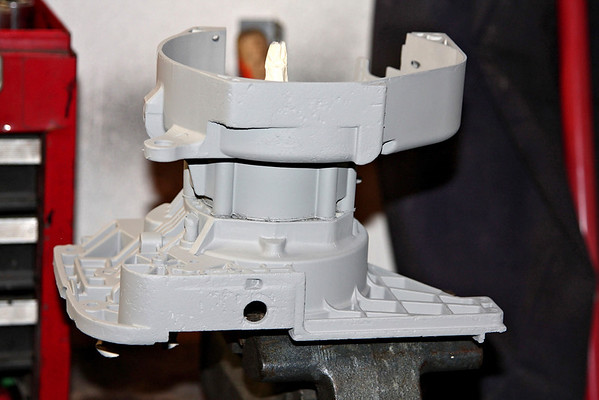

I decided it would be easier to get my small sandblasting cabinet out than to try to sand this all down. I knew it would do a better job of roughing up the surface in all the little nooks and cranies too. The bar cover was all chipped up so I stripped it all the way down, exposing some corrosion. The tank didn't have a lot of wear, so I left most of the original finish on it.

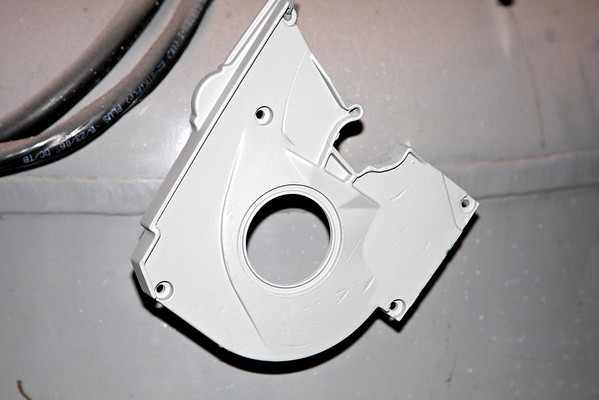

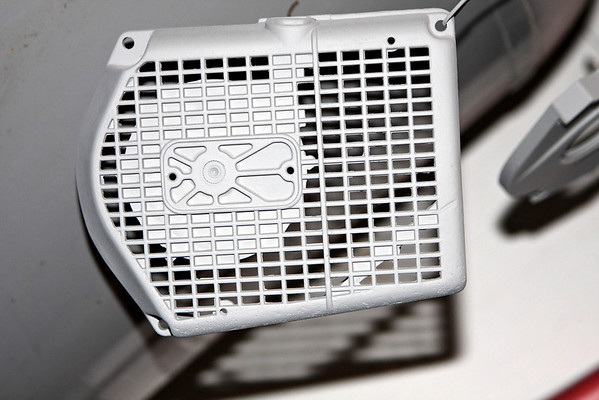

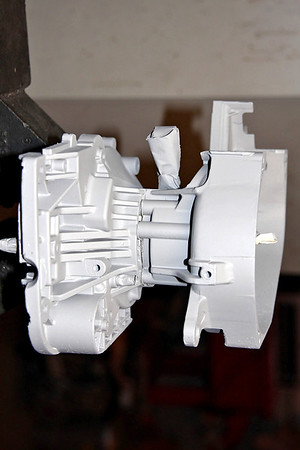

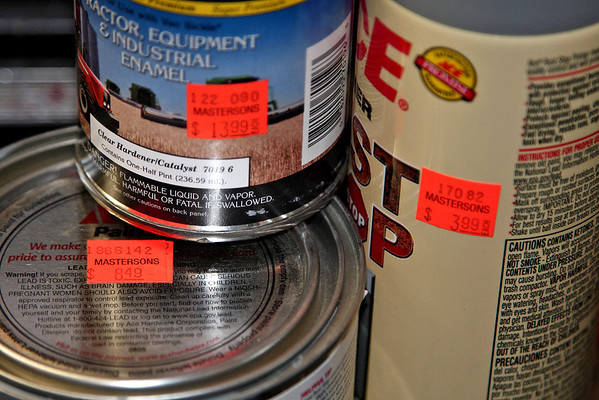

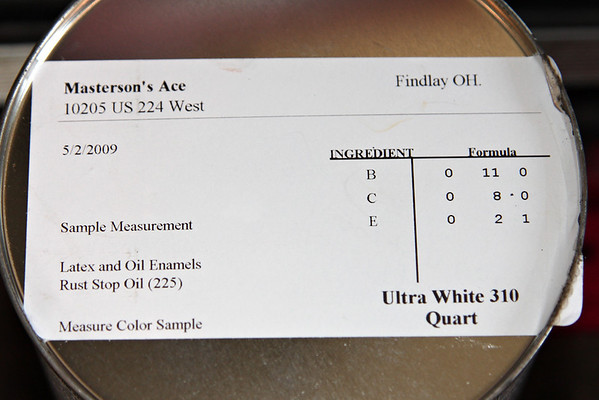

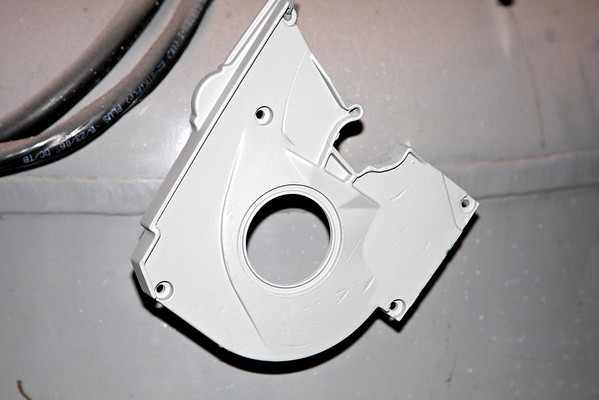

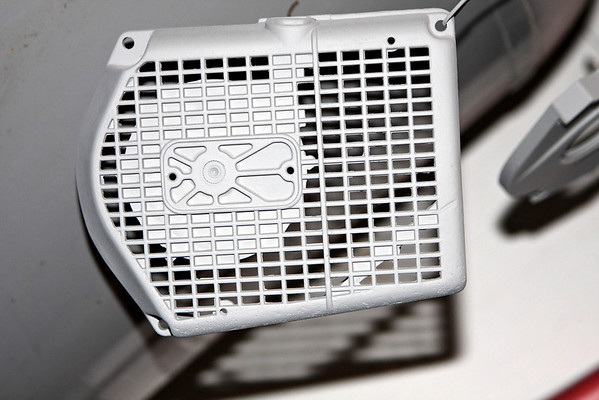

I used the primer from Ace that is intended for use with this paint. It took less than one can to do all the parts.

I used the primer from Ace that is intended for use with this paint. It took less than one can to do all the parts.