Trigger-Time

Addicted to ArboristSite

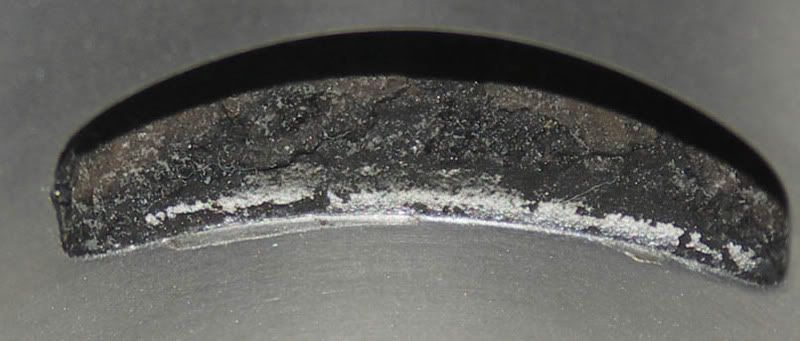

Bought a used 064 cylinder on e-bay, it had not been honed,

Cleaned it up, it was bad. Called seller, said he would send another

one right out (which he did) it looks very nice........But the chrome

is chipped above exhaust port.

Will it hurt anything?

Can it be fixed?

Or is it junk?

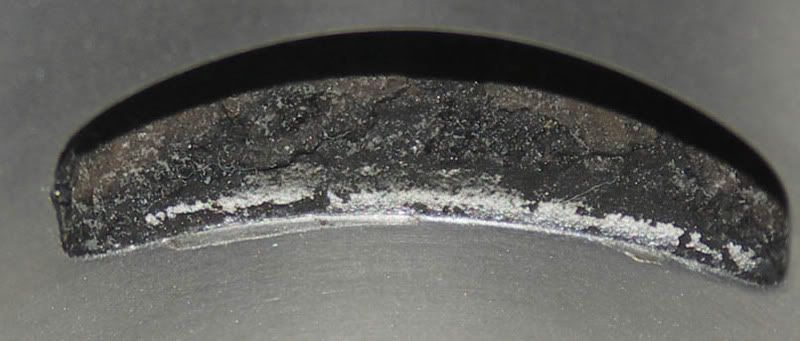

Cleaned it up, it was bad. Called seller, said he would send another

one right out (which he did) it looks very nice........But the chrome

is chipped above exhaust port.

Will it hurt anything?

Can it be fixed?

Or is it junk?