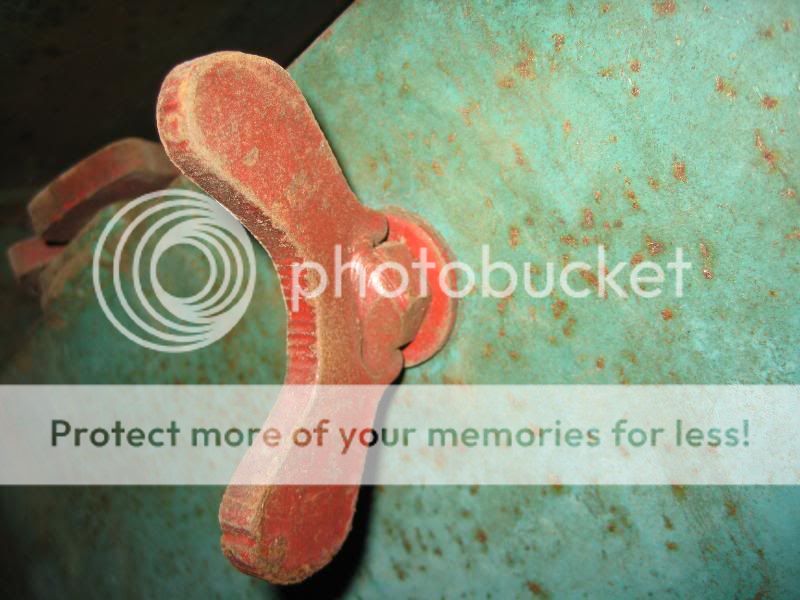

I tried looking for something like a Barshop for a while but I couldn't find anything... so I made my own. Sorry it's not the most recent picture but I think you get the idea. I've since ditched the CBN wheel and went with normal cutting wheels and made a stand. The next time I'm out in the shop I'll snap a picture of it's current state. It still looks like a prototype but it works well.

One thing I don't see on the Barshop is an easy way to adjust the grooving wheel to base distance, it looks fixed. So how do you center the grove for different bar thicknesses? That is why I included a vertical adjustment on the table. Yes, it's a re-purposed cross-slide vise.