pervert...

I think that makes YOU the pervert!

pervert...

pervert...

Yes. I've been using a bar that's way too small, and it has a tiny HSS insert. It worked, but not like it could have. 3/4" is the biggest bar I can hold, and I don't plan on hanging the bit out too far, just as long as I need to, no more.

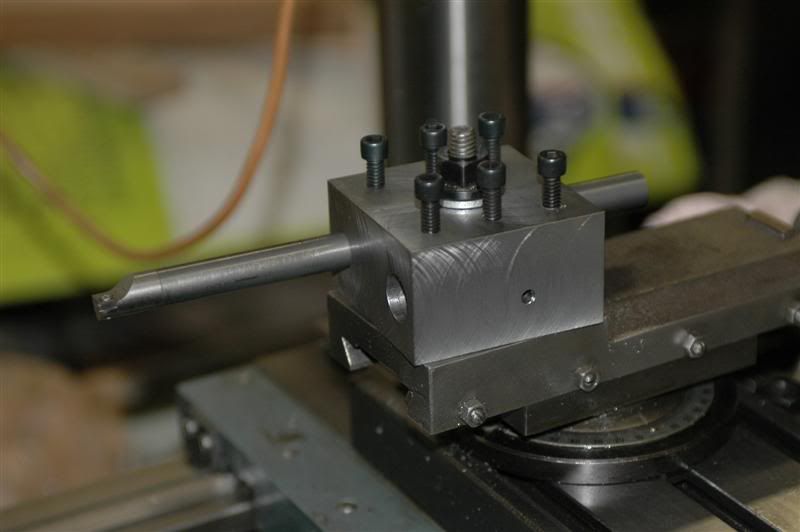

Toss the compound (ok, you can keep it), machine (or "obtain") a suitable block of steel, bolt it to the carriage using the compound mount post (or whatever) and use the lathe to bore whatever diameter you need for a bar. Also, make it so you can hold tooling. Light lathe compounds SUCK for rigidity; try a dedicated tool block when you don't need compound action and you'll be blown away by the improvement.

try a dedicated tool block when you don't need compound action and you'll be blown away by the improvement.

So you're just talking about getting rid of my quick change tool post? And just using a hunk of steel? Then I'd guess I'd have to shim to get the right height?

Pics of you guys' tooling and setups would be great

Pics of you guys' tooling and setups would be great

I have no use for them.

I've often thought about that, then I'd need a boring head? Once you bore the hole, how do you clamp the bar in the hole? Cut the block in half and bolt back together. I've seen the boring bar holders that bolt directly to where the tool post mounts.

So you're just talking about getting rid of my quick change tool post? And just using a hunk of steel? Then I'd guess I'd have to shim to get the right height?

Join my yahoo lathe group and look at all the pics in the folders and files for some great ideas. I thought so anyways...Bob

southbend10k : SouthBendLathe10k and lathe projects.

[snip]

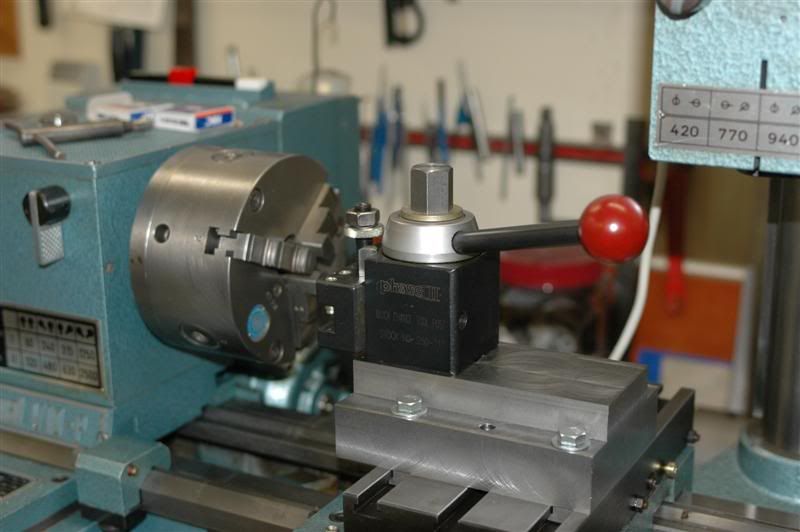

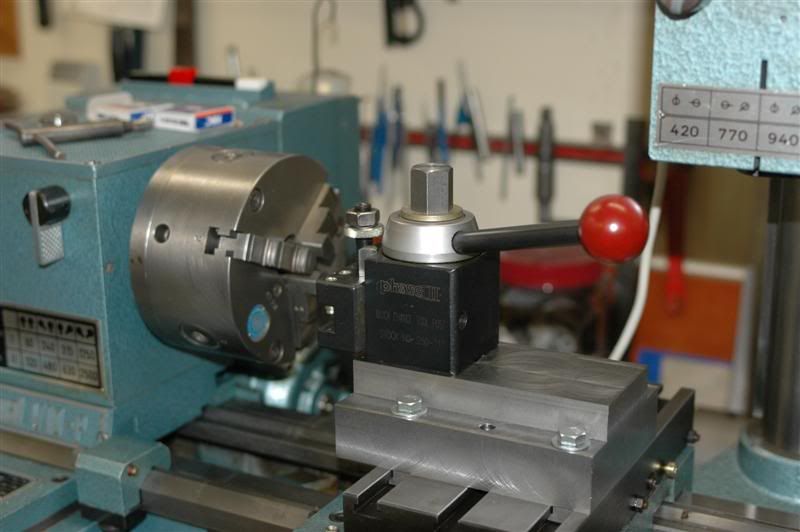

Here's the base block with an AXA toolpost (the block above can bolt to the top also). Massively rigid in comparison to a compound:

Is that an Emco Maximat you have there Lake?

I do not want to buy an old lathe that needs refurbed. If buying used, I wouldn't know a worn out machine from a good one. I was thinking something along the lines of a Grizzly. Of course, if someone I knew had a good older US made unit, that would be different. It MUST be small though

It's one of 2 V10P's i owned and sold to immediate neighbors (so i can still get to them). Should have kept the last one...

[snip]

To this:

Pics here : Emco v10P rebuild pictures by lakeside53 - Photobucket

I remember when you were cleaning up those rusty gears.

Very nice! The V10P is on my wish list. Its made in Austria so you can't go wrong. There was a local one advertised for $2600, but that's a bit high for me at the moment.