John Paul Sanborn

Above average climber

He bought one from United Rental that supposedly was OSHA approved.

There is a big difference between OSHA and ANSI approval. If I understand it right this is one of the areas where Gerstenberger and associates is still haggling with the OSHA. If you are going to use these methods, know the standards you are going by to the letter. My recollection of the Z133 there is no prescribed method of attachment of climber positioning systems; other then not interfering with the crane's functionality.

To answer the question in the OP I got mine from American Arborist. It was under 100 bucks but not by much if I recall.

I tell you from experinence you don't want to be on that hook. I mean you can ( but not really) but you have to really be careful. I was on a hook years ago, the operator was swinging it into the canopy, I was hollering for him to stop but he didn't. The clasp was opened by the little twigs and my rope popped out just as I got onto a limb but still did not have my lanyard on the tree. It could have been nasty.In fact I am still pissed off about the whole thing.

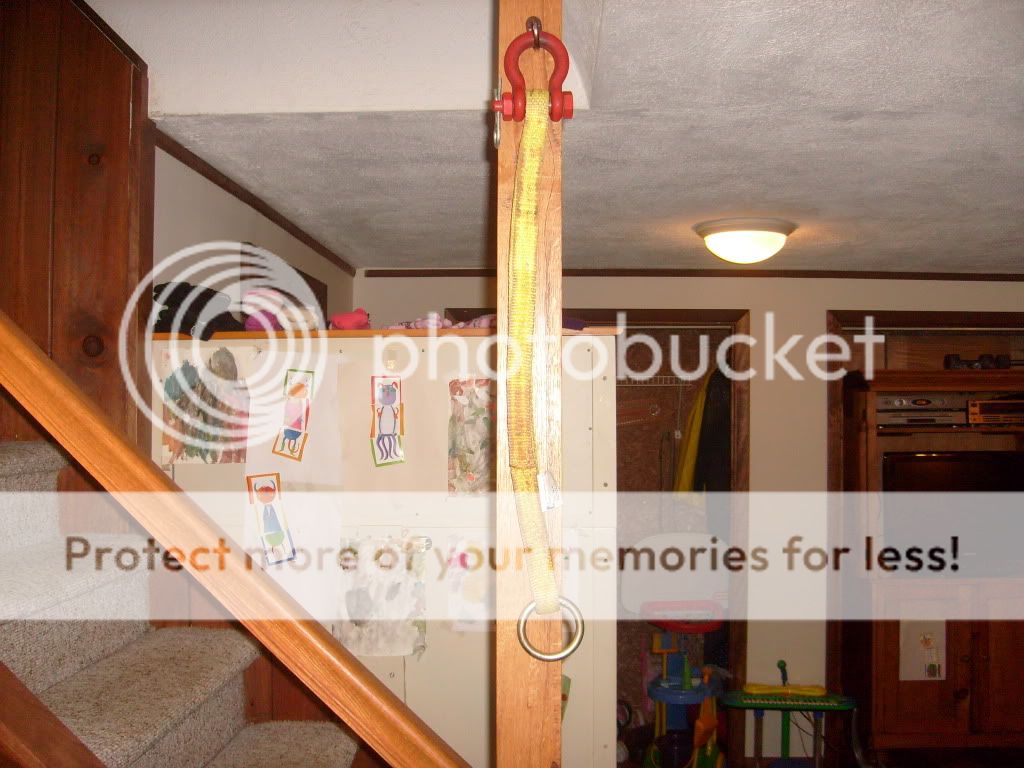

Don't know if it has been tested to this effect but if the disengaging device does not work or if the crane does not have one it seems to me that the clevis, if fed up into the sheave by an unalert op would likely break when under pressure.

People been riding the hook for decades. If the sub op says I have to use the clevis (on rare occasion) I will but if it is not there....no biggie. I ride my own without one. Been doing it for, again, decades...and I am still here.

Lots of these rules are being made by white skinned, soft handed, office type, wannabe's that haven't got a clue. (kinda like Jomoco)