Wife'nHubby

Addicted to ArboristSite

Here is the first hyd. connection I made. Also shows the u-bold which goes thru pre-drilled holes in the i-beam.

I haven't made this connection yet because I have a question here: Should I add hyd. fluid into the cylinder before completing this connection?

Here's my first hyd. connection. I have it tight enough now that now shiny threads are showing - again, I will have someone give this another crank or two before firing.

The fluid tank has an air hole, will this air hole be enough to release air in the hydraulic lines when I add fluid or should I remove the cap when running it during the initial fluid fill?

Don't forget, I will have some male I can corner to crank down all the connections I made before I fire it up.

Shari

My Dad, if he were still living, would laugh at my PP but would probably be proud that I at least tried this on my own. (I was Dad's "tool gal" when he worked on his machinery.) Wish me luck! I will report back.

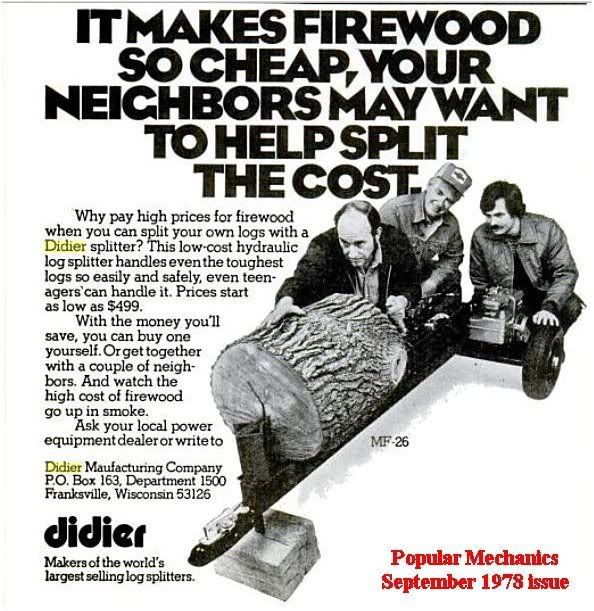

My Dad, if he were still living, would laugh at my PP but would probably be proud that I at least tried this on my own. (I was Dad's "tool gal" when he worked on his machinery.) Wish me luck! I will report back.Hey, thats on old Didier splitter, mine looked just like it when I bought it. You're on the right track, doing fine. Fill the cylinder, finish the connections, fill the tank about 3/4 of the way and fire it up. I'd leave the cap off of the tank to monitor the oil level. Actually, I'd take this opportunity to junk that little tank and replace it with one that will hold more than a quart. I've seen people use propane tanks on their Didiers in place of the originals. Just a suggestion. Good luck!

That's a good idea the OP could also try a expired 20lb propane tank.If you knew someone who could do some modifications and weld work one of these would be a cheap option.

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=41712

Wouldn't be too bad of a job to drill a couple of holes in one and weld pipe fittings on. Measure the space you have available between the tire and hyd. pump to make sure it'll fit. If not, elevating it above the pump won't hurt, its acutally a good idea.

What you already have will work (as you know) but more volume = less heat = longer cylinder life. Something to consider.