sILlogger

Addicted to ArboristSite

hmm...looks like i should have kept my BB kit and played with it more...the next saw i build is gonna get the works..ported, milled cylinder and pop-up....but with it be a BB or oem???? now that is the question!!

Howdy,

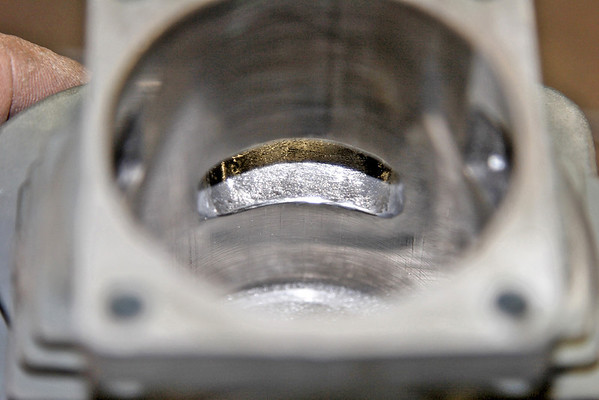

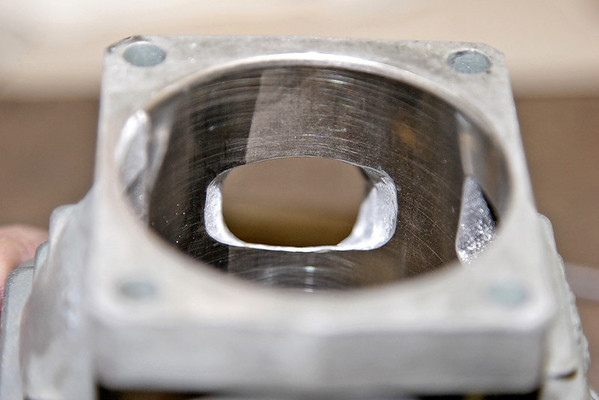

I'm concerned with what you've found after opening back up. The main concern is the flaking. We changed these to a NiSi coating from chrome and there is no way it should flake. Do you have a BB 066 kit or the BBN 066 kit? We stand behind these and really want them to be as good as possible. If it's not to late, can you supply some pix?

Gregg

Howdy,

I'm concerned with what you've found after opening back up. The main concern is the flaking. We changed these to a NiSi coating from chrome and there is no way it should flake. Do you have a BB 066 kit or the BBN 066 kit? We stand behind these and really want them to be as good as possible. If it's not to late, can you supply some pix?

Gregg

but man did it run good!!

but man did it run good!!

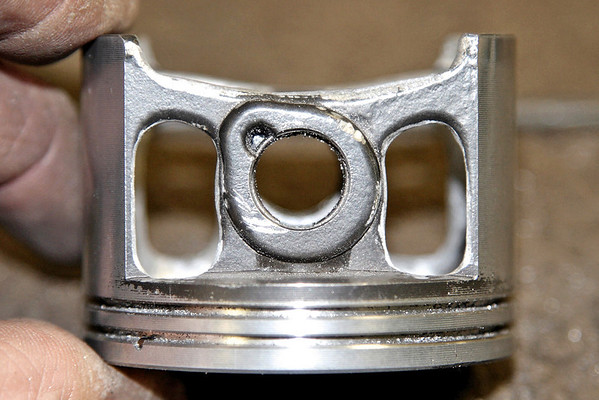

Brad.....When you ported this cylinder all you did was grind out the chamfer. Try rechamfering it with craytex in a fordom or dremel. It should clean up....but if not, have them give you a new one.

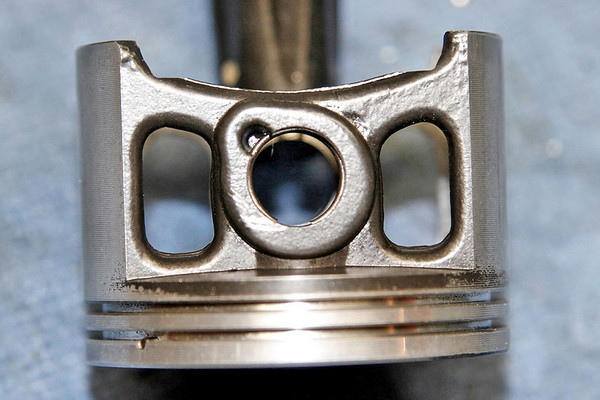

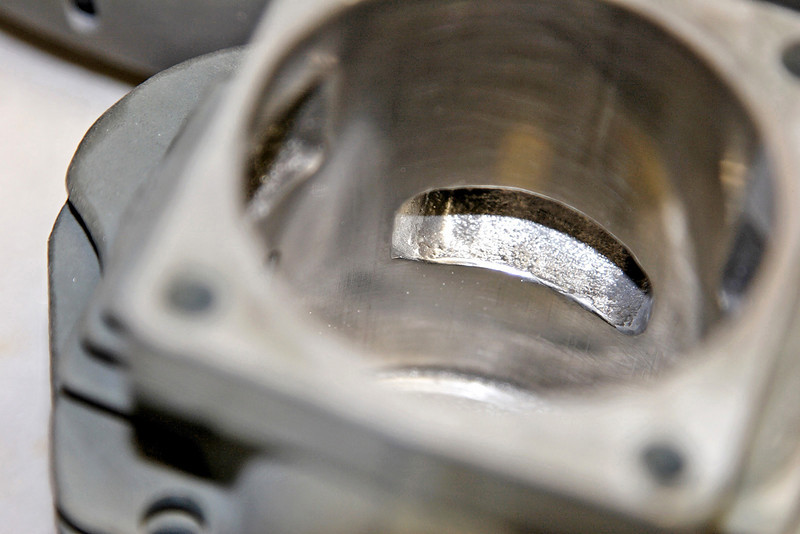

siILlogger, the edge of your ports do look aweful sharp. Of course, it's hard to tell in a pic. I would guess that yours was an issue of catching a ring, rather than a problem with flaking chrome.

So far so good. I finished putting it together and tuned it up. She tuned to 14,400, which is 700 higher than before. Afterwards I removed the muffler cover and the piston looks perfect so far. We'll have to see how it holds up in real use.

It's hard to tell from the pix but, the silver color of the cylinder lining sure looks like the chrome coating. The NiSi has a reddish tint to it. I checked your order and it should have been the NiSi version. Sorry for the mix up. I'll head another kit out to you right away. Looks like we shipped the last one by mail. Will that work for you again, or would you prefer another method?

It's hard to tell from the pix but, the silver color of the cylinder lining sure looks like the chrome coating. The NiSi has a reddish tint to it. I checked your order and it should have been the NiSi version. Sorry for the mix up. I'll head another kit out to you right away. Looks like we shipped the last one by mail. Will that work for you again, or would you prefer another method?

you should do a more even and better job chamfering the top and bottom edges of the ports.